Abstract

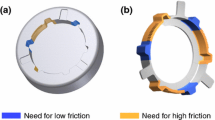

Sheet-bulk metal forming (SBMF) is characterized by successive and/or simultaneous occurrence of quite different load conditions regarding stress and strain states. These conditions significantly influence the material flow and thus the geometrical accuracy of the components. To improve the product quality a control of the material flow is required. An appropriate approach is given by locally adapted tribological conditions due to surface modifications of tool and workpiece, so-called tailored surfaces. Within the present study different methods to adapt the surfaces are presented and investigated with respect to their tribological effectiveness in SBMF. In a first step, requirements regarding necessary adaptions of the friction values for two SBMF processes are numerically defined. Based on the requirements different tailored surfaces are presented and analyzed regarding their tribological influence. Finally, the potential of surface modifications to improve SBMF processes is shown.

Similar content being viewed by others

References

Kleiner M, Geiger M, Klaus A (2003) Manufacturing of lightweight components by metal forming. Ann CIRP 52(2):521–542

Merklein M, Allwood JM, Behrens BA, Brosius A, Hagenah H, Kuzman K, Mori K, Tekkaya AE, Weckenmann A (2012) Bulk forming of sheet metal. Ann CIRP 61(2):725–745

Klocke F, Dambon O, Behrens B (2011) Analysis of defect mechanisms in polishing of tool steels. Prod Eng Res Dev 5(5):475–483

Lange K (1985) Handbook of metal forming. McGraw-Hill, New York

Lange K, Kammerer M, Pöhlandt K, Schöck J (2008) Fließpressen. Springer, Berlin

Bartz W (2004) Tribologie und Schmierung bei der Massivumformung. Expert Verlag, Renningen

Tosha K (2008) Effect of shot peening on surface integrity. In: Tosha K (ed) Prof. ICSP 10. DGM-Informationsgesellschaft, Tokyo

Vierzigmann U, Schneider T, Koch J, Gröbel D, Merklein M, Engel U, Hense R, Biermann D, Krebs E, Kersting P, Henning L, Denkena B, Herper J, Tillmann W (2013) Untersuchungen von Tailored Surfaces für die Blechmassivumformung mittels angepasstem Ringstauchversuch. In: Merklein M, Behrens BA, Tekkaya AE (eds) 2. Workshop Blechmassivumformung. Bamberg, Meisenbach, pp 137–162

Fontaine J, Donnet C, Erdemir A (2008) Fundamentals of the Tribology of DLC Coatings. In: Donnet C, Erdemir A (eds) Tribology of Diamond-Like Carbon Films. Springer, New York, pp 139–154

Strondl C, Carvalho NM, DE Hosson JTHM, Krug TG (2005) Influence of energetic ion bombardment on W-C: H coatings deposited with W and WC targets. Surf Coat Technol 200(1–4):1142–1146

Voevodin AA (2008) Hard DLC growth and inclusion in nanostructured wear-protective coatings. In: Donnet C, Erdemir A (eds) Tribology of diamond-like carbon films. Springer, New York, pp 263–281

Hetzner H, Tremmel S, Wartzack S (2012) Amorphous carbon coatings for locally adjusted tribological properties in sheet bulk metal forming. Key Eng Mater 504–506:969–974

Polcar T, Cvrcek L, Siroky P, Novák R (2005) Tribological characteristics of CrCN coatings at elevated temperature. Vacuum 80(1–3):113–116

Zhoua H, Chena L, Wanga W, Renc LQ, Shana HY, Zhanga ZH (2005) Abrasive particle wear behavior of 3Cr2W8V steel processed to bionic non-smooth surface by laser. Mater Sci Eng A 412(1–2):323–327

Kitamura K, Makino T, Nawa M, Miyata S (2016) Tribological effects of punch with micro-dimples in blanking under high hydrostatic pressure. CIRP Ann Manuf Technol (in press)

Kersting P, Gröbel D, Merklein M, Sieczkarek P, Wernicke S, Tekkaya AE, Krebs E, Freiburg D, Biermann D, Weikert T, Tremmel S, Stangier D, Tillmann W, Matthias S, Reithmeier E, Löffler M, Beyer F, Willner K (2016) Experimental and numerical analysis of tribological effective surfaces for forming tools in sheet-bulk metal forming. In: Production engineering. Research and development, pp 1–14. doi:10.1007/s11740-015-0651-6

Zabel A, Surmann T, Peuker A (2008) Surface structuring and tool path planning for efficient milling of dies. In: 7th international conference on high speed machining proceedings, pp 155–160

Denkena B, Grove T, Lucas H (2016) Influences of grinding with Toric CBN grinding tools on surface and subsurface of 1.3344 PM steel. J Mater Process Technol 229:541–548

Löffler M, Andreas K, Engel U, Merklein M (2016) Applicability of blasted blanks for adaption of tribological conditions in sheet-bulk metal forming. Procedia CIRP 45:239–242

Löffler M, Gröbel D, Engel U, Andreas K, Merklein M (2015) Analysis of effectiveness of locally adapted tribological conditions for improving product quality in sheet-bulk metal forming. Appl Mech Mater 794:81–88

Löffler M, Schneider T, Vierzigmann U, Engel U, Merklein M (2015) Locally adapted tribological conditions as a method for influencing the material flow in sheet-bulk metal forming processes. Key Eng Mater 639:267–274

Acknowledgments

This work was supported by the German Research Foundation (DFG) within the scope of the Transregional Collaborative Research Centre on sheet-bulk metal forming (CRC/TR 73, Subprojects A1, A2, B2, B3, B4, B5, B8 and C1).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Löffler, M., Andreas, K., Engel, U. et al. Tribological measures for controlling material flow in sheet-bulk metal forming. Prod. Eng. Res. Devel. 10, 459–470 (2016). https://doi.org/10.1007/s11740-016-0695-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-016-0695-2