Abstract

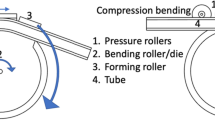

Three-roll-push-bending (TRPB) is an innovative and flexible freeform bending process for the manufacturing of tube geometries with a continuous distribution of curvature along the bending line. The shaping is done kinematically, which means that the bending line is defined solely by the defined movement of the bending tools. Measurements of the resulting curvature have shown a characteristic oscillating transition zone over an extensive length of the part until a constant curvature is reached. The quantitative description of the transition zone and typical bending characteristics, such as radius of curvature and bending angle, is only possible to a limited extent using the common measurement approach. This paper presents an algorithm, which allows the determination of typical bending characteristics and the quantitative description of transition zones along the curvature distribution. For specimen components the results provided by this method are compared to those provided by a common method for the examination of bending radii. The algorithm forms the basis for investigating the influence of machine, tool and semi-finished parameters on the transition zone at the bending section.

Similar content being viewed by others

References

Vollertsen F, Sprenger A, Kraus J, Arnet H (1999) Extrusion, channel, and profile bending: a review. J Mater Process Technol 87:1–27

Engel B, Kersten S (2013) Bending test for the characterization of Freeform-Bending processes. In: Proceedings of the Metal Forming, Krakau, Vol. 14, pp 1235–1238

Tekkaya AE, Becker C, Staupendahl D (2015) The impact of torsion on the bending curve during 3D bending of thin-walled tubes—a case study on forming helices. Key Eng Mater 651–653:1595–1601

Plettke R, Vatter PH, Vipavc D (2012) Basics of Process Design for 3D freeform bending. In: Steel research international: 14th Int. Conf. on Metal Forming, pp 307–301

VDI 3431 (2014) Bending of profiles—testing notes for profile beind elements, version 2014–06, Beuth Verlag GmbH, Berlin

Selvaggio A, Dirksen U, Tekkaya AE, Schikorra M, Kleiner M (2009) Increasing the production accuracy of profile bending with methods of computational intelligence. Evolut Comput 17(4):561–576 (MIT Press)

Engel B, Kersten S (2010) Sensitivitätsanalyse beim Freiformbiegen von Rohrprofilen. 30. EFB-Kolloquiums Blechverarbeitung 2010. EFB Tagungsband T31:125–138

Wangyu L, Kaidong H (2016) Research on the three-roll-push-bending forming rules for improving processing precision. Int J Adv Manuf Technol 90:769–773

Engel B, Groth S (2016) Auswirkung der zustellbewegung beim drei-rollen-schubbiegen auf charakteristische biegemerkmale in: konferenzband zum 35. Verformungskundlichen Kolloquium der Montanuniversität Leoben, pp 105–110, ISBN 978-3-902078-21-6

Groth S, Engel B (2017) Determination of the bending line of bent tubes by an analytical plasticity model considering process kinematics. In: Proceedings Conference on Plasticity, Damage and Fracture, Puerto Vallarta (Mexico)

Kopfer P (2011) Improving the curvature of bent profiles by adjusting the process kinematics of Three-Roll-Pushbending Process, 4th Dortmund Tube and Profile bending Colloquium, vol 4, pp 127–130

Ghiotti A, Enrico Simonetto S, Bariani P (2017) Springback measurement in three roll push bending process of hollow structural sections. CIRP Ann 66(1):289–292

Quarteroni A, Sacco R, Saleri F (2002) Numerical mathematics, 2nd edn. Springer, Berlin

Reinsch C-H (1967) Smoothing by spline functions. Numer Math 10.3:177–183

Frenet JF (1852) Sur les courbes à double courbure. J Math Pures Appl 17:437–447

Serret JA (1851) Sur quelques formules relatives à la théorie des courbes à double courbure. J Math Pures Appl 16:193–207

DIN ISO 286 (1988) ISO-system für Grenzmaße und passungen: grundlagen für toleranzen, abmaße und passungen, version 1990–11. Beuth Verlag, Berlin

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Groth, S., Engel, B. & Langhammer, K. Algorithm for the quantitative description of freeform bend tubes produced by the three-roll-push-bending process. Prod. Eng. Res. Devel. 12, 517–524 (2018). https://doi.org/10.1007/s11740-018-0795-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-018-0795-2