Abstract

In contrast to common and classical joining technologies for composite/metal hybrid structures such as bonding and riveting, profile and contour joints offer a promising potential for novel lightweight hybrid structures. Contour joints with form locking elements on multiple scale levels enable to pass very high loads into rod- and tube-shaped fibre reinforced structures and promise high degrees of material utilization for the composite part. This paper demonstrates the advantage of multi-scale structured load introduction elements. First the intrinsic manufacturing process, whereas the thermoplastic tape braided preform is simultaneously consolidated and formed into the metallic load introduction element is shown. Numerical investigations on the macro- and generic microscale demonstrate the potential to trigger cohesive or adhesive failure by appropriate designed form locking elements. The extensive experimental investigation of meso-, macro- or combined-structured tubular specimen shows the beneficial effect of multi-scale structuring to increase the joining strength. Concluding advises for the contour joints’ design are given.

Similar content being viewed by others

References

Töpker J, Schulz J, Haberstroh E, Michaeli W (2000) Krafteinleitungselemente und Verbindungstechniken bei endlosfaserverstärkten thermoplastischen Hohlprofilen, 3. AVK-TV Tagung, Baden-Baden

Fischer T, Schürmann H (2005) Der Pressverband als Krafteinleitungs-Element in Faser-Kunststoff-Verbund-Wellen. 11. Nationales Symposium SAMPE Deu tschland e.V

Reimerdes H-G, Menking M, Goetz F (1995) Konstruktive Auslegung von Fügeverbindungen in Leichtbaustrukturen. DGLR, Vortrag Nr. DGLR-JT 95-079

Mori K, Bay N, Fratini L, Micari F, Tekkaya AE (2013) Joining by plastic deformation. CIRP annals—manufacturing technology, vol 60, pp 673–694

Fleischer J, Ochs A, Dosch S (2012) The future of lightweight manufacturing—production related challenges when hybridizing metals and continuous fiber-reinforced plastics. In: Proceedings of international conference on “New developments in Sheet Metal Forming”, Stuttgart, pp 51–70

Helms O (2006) Construction and technological implementation of highly stressed load introduction systems for new lightweight structures in fiber composite design. PhD Thesis, TU Dresden

Hufenbach W, Gude M, Helms O, Ulbricht U (2008) Novel lightweight aircraft components in multi-material design with adapted load-introduction systems. European conference on materials and structures in aerospace (EUCOMAS), Berlin, 26–27.05.2008

Liu Y, Zwingmann B, Schlaich M (2015) Carbon fiber reinforced polymer for cable structures—a review. Polymers 7(10):2078–2099

Fleischer J, Koch S, Coutandin S (2015) Manufacturing of polygon fiber reinforced plastic profiles by rotational molding and intrinsic hybridization. Prod Eng Res Devel 9:317–328

Kim H, Lee D (2005) Optimal design of the press fir joint for hybrid aluminum/composite drive shaft. Compos Struct 70:33–47

Gude M, Lenz F, Gruhl A, Witschel B, Ulbricht A, Hufenbach W (2015) Design and automated manufacturing of profiled composite driveshafts. Sci Eng Compos Mater 22:187–197

Wang Z, Bobbert M, Dammann C, Zinn C, Lauter C, Mahnken R, Meschut G, Schaper M, Tröster T (2016) Influences of interface and surface pre-treatment on the mechanical properties of metal-CFRP hybrid structures manufactured by resin transfer moulding. Int J Autom Compos 2(3/4):272–298

Baburaji EG, et al (2007) Enhancement of adhesive joint strength by laser surface modification. Int J Adhes Adhes 27:268–276

Elter A (2015) Hochbelastbare, reibkraftschlüssige Krafteinleitungen für Faser-Kunststoff-Verbunde auf Basis strukturierter Oberflächen. Dissertation, Technische Universität Darmstadt, Shaker Verlag

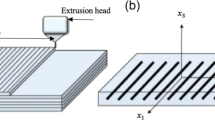

Barfuss D, Grützner R, Garthaus C, Gude M, Müller R, Langrebe D (2016) Intrinsic manufacture of hollow thermoplastic composite/metal structures. In: Proceedings 19th ESAFORM, 27th–29th April 2016, AIP Publishing

Garthaus C, Barfuss D, Witschel B, Gude M (2015) Tape braiding: high-performance fibre reinforced thermoplastic profile structures. JEC Composites Magazine, no. 96, pp 62–64

Barfuss D, Grützner R, Garthaus C, Gude M (2016) Design and intrinsic manufacturing of positive locking fibre thermoplastic-metal hollow structures. In: Proceedings ECCM17, Munich 26–30th June 2016

Hirsch F, Kästner M (2017) Microscale simulation of adhesive and cohesive failure in rough interfaces. Eng Fract Mech 178:416–432

Barfuss D, Garthaus C, Gude M, Grützner R (2017) Design of multi-scale structured AL-CF/PA6 contour joint. Int J Autom Compos, special issue “Fibre-Composite-based Multi-Material and Hybrid Systems for structural Applications”, vol 2, no. 3/4, pp 299–315

Alfaro M, Cid; Suiker A, Verhoosel C, de Borst R (2010) Numerical homogenization of cracking processes in thin fibre-epoxy layers. Eur J Mech A Solids 29(2):119–131

Lemaitre J (1985) A continuous damage mechanics model for ductile fracture. Transactions of the ASME. J Eng Mater Technol 107(1):83–89

Camanho PP, Davila CG, de Moura MF (2003) Numerical simulation of mixed-mode progressive delamination in composite materials. J Compos Mater 37(16):1415–1438

Kim WS, Yun IH, Lee JJ, Jung HT (2010) Evaluation of mechanical interlock effect on adhesion strength of polymer–metal interfaces using micro-patterned surface topography. Int J Adhes Adhes 30:408–417

Cuntze R (1998) The failure mode concept—a new comprehensive 3D-strenght analysis concept for any brittle and ductile behaving material. In: Proceedings of European Conferences of Spacecraft Structures. Materials and Mechanical Testing, Braunschweig, Nov, 26th–30th of June, pp 269–287

Hsiao HM, Daniel IM (1996) Elastic properties of composites with fiber waviness. Compos Part A 27A:931–943

Acknowledgements

The authors gratefully acknowledge the funding of this work by the German Research Foundation, DFG, within the priority program 1712: Intrinsic hybrid composites for lightweight structures—basics of manufacturing, characterization and design.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Barfuss, D., Grützner, R., Hirsch, F. et al. Multi-scale structuring for thermoplastic-metal contour joints of hollow profiles. Prod. Eng. Res. Devel. 12, 229–238 (2018). https://doi.org/10.1007/s11740-018-0800-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-018-0800-9