Abstract

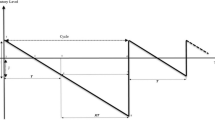

In this paper a multi-objective mathematical model is proposed for multi-item EOQ model considering partial backordering and defective supply batches. In order to consider real world situations, different stochastic operational constraints are considered and implemented under uncertainty. For the first time in this research, the rate of partial backordering is considered as decision variable. The aim is to determine time interval between successive supply deliveries, rate of partial backordering and filling rate from stock in order to minimize total inventory costs including holding, backordering and ordering costs, while, minimizing required warehouse space. Due to complexity and nonlinearity of the proposed mathematical model from one hand and importance of providing the decision maker with efficient Pareto optimal solutions, five meta heuristic algorithms as well as one hybrid exact solution method are utilized to solve the problem. To determine the most efficient solution method, the performance of the algorithms is investigated through a deep computational analysis considering different measures including diversity, number of Pareto optimal solutions, spacing and computation time. In addition, single factor ANOVA is utilized to determine significant difference among algorithms at ninety-five percent confidence level to demonstrate the superior algorithm.

Source Salehi et al. (2016)

Source Mirjalili et al. (2016)

Similar content being viewed by others

References

Balande U, Shrimankar D (2017) An oracle penalty and modified augmented Lagrangian methods with firefly algorithm for constrained optimization problems. Oper Res Int J 1–26. https://doi.org/10.1007/s12351-017-0346-1

Bera AK, Jana DK (2017) Multi-item imperfect production inventory model in Bi-fuzzy environments. OPSEARCH 54(2):260–282

Cárdenas-Barrón LE (2009) Economic production quantity with rework process at a single-stage manufacturing system with planned backorders. Comput Ind Eng 57:1105–1113

Chan WM, Ibrahim RN, Lochert PB (2003) A new EPQ model: integrating lower pricing, rework and reject situations. Prod Plann Control 14(7):588–595

Cheng MC, Hsieh TP, Lee HM, Ouyang LY (2017) Optimal ordering policies for deteriorating items with a return period and price-dependent demand under two-phase advance sales. Oper Res Int J 1–20. https://doi.org/10.1007/s12351-017-0359-9

Chiu YP (2003) Determining the optimal lot size for the finite production model with random defective rate, the rework process, and backlogging. Eng Optim 35(4):427–437

Chung KJ, Huang YF (2006) Retailer’s optimal cycle times in the EOQ model with imperfect quality and a permissible credit period. Qual Quant 40(1):59–77

Eroglu A, Ozdemir G (2007) An economic order quantity model with defective items and shortages. Int J Prod Econ 106:544–549

Fazli-Khalaf M, Khalilpourazari S, Mohammadi M (2017) Mixed robust possibilistic flexible chance constraint optimization model for emergency blood supply chain network design. Ann Oper Res 1–31. https://doi.org/10.1007/s10479-017-2729-3

Hsu JT, Hsu LF (2013) An EOQ model with imperfect quality items, inspection errors, shortage backordering, and sales returns. Int J Prod Econ 143:162–170

Hsu LF, Hsu JT (2014) Economic production quantity (EPQ) models under an imperfect production process with shortages backordered. Int J Syst Sci 47:852–867

Khalilpourazari S, Khalilpourazary S (2016) Optimization of production time in the multi-pass milling process via a Robust Grey Wolf Optimizer. Neural Comput Appl 1–16. https://doi.org/10.1007/s00521-016-2644-6

Khalilpourazari S, Khalilpourazary S (2017a) A lexicographic weighted Tchebycheff approach for multi-constrained multi-objective optimization of the surface grinding process. Eng Optim 49(5):878–895

Khalilpourazari S, Khalilpourazary S (2017b) An efficient hybrid algorithm based on water cycle and moth-flame optimization algorithms for solving numerical and constrained engineering optimization problems. Soft Comput 1–24. https://doi.org/10.1007/s00500-017-2894-y

Khalilpourazari S, Khalilpourazary S (2018) A Robust Stochastic Fractal Search approach for optimization of the surface grinding process. Swarm Evol Comput 38:173–186

Khalilpourazari S, Khamseh AA (2017) Bi-objective emergency blood supply chain network design in earthquake considering earthquake magnitude: a comprehensive study with real world application. Ann Oper Res 1–39. https://doi.org/10.1007/s10479-017-2588-y

Khalilpourazari S, Mohammadi M (2016) Optimization of closed-loop Supply chain network design: a water cycle algorithm approach. In: 12th International conference on industrial engineering (ICIE), pp 41–45

Khalilpourazari S, Pasandideh SHR (2016) Bi-objective optimization of multi-product EPQ model with backorders, rework process and random defective rate. In: 12th international conference on industrial engineering (ICIE), pp 36–40

Khalilpourazari S, Pasandideh SHR (2017) Multi-item EOQ model with nonlinear unit holding cost and partial backordering: moth-flame optimization algorithm. J Ind Prod Eng 34(1):42–51

Khalilpourazari S, Pasandideh SHR, Niaki STA (2016) Optimization of multi-product economic production quantity model with partial backordering and physical constraints: sQP, SFS, SA, and WCA. Appl Soft Comput 49:770–791

Khan M, Jaber MY, Wahab MJM (2010) Economic order quantity for items with imperfect quality with learning in inspection. Int J Prod Econ 124(1):87–96

Maddah B, Jaber MY (2008) Economic order quantity for items with imperfect quality: revisited. Int J Prod Econ 112(2):808–815

Mirjalili S, Saremi S, Mirjalili SM, Coelho LS (2016) Multi-objective grey wolf optimizer: a novel algorithm for multi-criterion optimization. Expert Syst Appl 47:106–119

Mohammadi M, Khalilpourazari S (2017) Minimizing makespan in a single machine scheduling problem with deteriorating jobs and learning effects. In: Proceedings of the 6th international conference on software and computer applications. ACM, pp 310–315

Mokhtari H, Rezvan MT (2017) A single-supplier, multi-buyer, multi-product VMI production-inventory system under partial backordering. Oper Res Int J 1–21. https://doi.org/10.1007/s12351-017-0311-z

Nobil AH, Sedigh AHA, Cárdenas-Barrón LE (2017) A multiproduct single machine economic production quantity (EPQ) inventory model with discrete delivery order, joint production policy and budget constraints. Ann Oper Res 1–37. https://doi.org/10.1007/s10479-017-2650-9

Pasandideh SHR, Khalilpourazari S (2018) Sine cosine crow search algorithm: a powerful hybrid meta heuristic for global optimization. Cornell Univer Library 1–15. arXiv:1801.08485

Pasandideh SHR, Niaki STA, Asadi K (2015a) Optimizing a bi-objective multi-product multi-period three echelon supply chain network with warehouse reliability. Expert Syst Appl 42(5):2615–2623

Pasandideh SHR, Niaki STA, Gharaei A (2015b) Optimization of a multiproduct economic production quantity problem with stochastic constraints using sequential quadratic programming. Knowl Based Syst 84:98–107

Sadollah A, Eskandar H, Kim JH (2015) Water cycle algorithm for solving constrained multi-objective optimization problems. Appl Soft Comput 27:279–298

Salameh MK, Jaber MY (2000) Economic production quantity model for items with imperfect quality. Int J Prod Econ 64(1–3):59–64

Salehi H, Taleizadeh AA, Tavakkoli-Moghaddam R (2016) An EOQ model with random disruption and partial backordering. Int J Prod Res 54(9):2600–2609

Skouri K, Konstantaras I, Lagodimos AG, Papachristos S (2014) An EOQ model with backorders and rejection of defective supply batches. Int J Prod Econ 155:148–154

Taleizadeh AA, Noori-daryan M (2016) Pricing, inventory and production policies in a supply chain of pharmacological products with rework process: a game theoretic approach. Oper Res Int J 16(1):89–115

Taleizadeh AA, Sari-Khanbaglo MP, Cárdenas-Barrón LE (2017) Outsourcing rework of imperfect items in the economic production quantity (EPQ) inventory model with backordered demand. IEEE Trans Syst Man Cybern Syst 1–12

Thangam A, Uthayakumar R (2010) Optimal pricing and lot-sizing policy for a two-warehouse supply chain system with perishable items under partial trade credit financing. Oper Res Int J 10(2):133–161

Wang GG, Deb S, Zhao X, Cui Z (2016) A new monarch butterfly optimization with an improved crossover operator. Oper Res Int J 1–25. https://doi.org/10.1007/s12351-016-0251-z

Wee HM, Yu J, Chen MC (2007) Optimal inventory model for items with imperfect quality and shortage backordering. Omega 35(1):7–11

Yassine A, Maddah B, Salameh M (2012) Disaggregation and consolidation of imperfect quality shipments in an extended EPQ model. Int J Prod Econ 135:345–352

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Khalilpourazari, S., Pasandideh, S.H.R. Multi-objective optimization of multi-item EOQ model with partial backordering and defective batches and stochastic constraints using MOWCA and MOGWO. Oper Res Int J 20, 1729–1761 (2020). https://doi.org/10.1007/s12351-018-0397-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12351-018-0397-y