Abstract

This study is devoted to investigate the effects of the bump pitch on the capillary underfill flow. A micro particle image velocimetry (μPIV) system was used to visualize the flows and the shape of meniscus. Transparent flip chip specimens with quadrilateral bump arrangements were fabricated by etching silicon on glass wafer. Six bump pitches from 60 to 160 μm were tested and glycerin was dispensed to fill into the flip chip specimens. From the present experiments, it is shown that the overall filling speed becomes faster at larger bump pitch and changes abruptly when the bump pitch is twice the bump diameter. The detailed meniscus movement also has different behavior if the bump pitch gets smaller and larger than twice the bump diameter. The variation of dynamic contact angle is synchronized with that of the meniscus velocity throughout the whole process. During the interaction with the flip chip bumps, the contact line of the meniscus becomes concave or convex. The curvature of the concave and convex lines is larger at the smaller bump pitch.

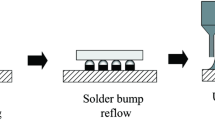

Graphical Abstract

Similar content being viewed by others

References

Han S, Wang KK (1997) Analysis of the flow of encapsulant during underfill encapsulation of flip-chips. IEEE Trans Compon Package Manuf Technol B 20:424–433

Hashimoto T, Shin-ichiro T, Morinishi K, Satofuka N (2008) Numerical simulation of conventional capillary flow and no-flow underfill in flip-chip packaging. Comput Fluids 37:520–523

Jong WR, Kuo TH, Ho SW, Chiu HH, Peng SH (2007) Flows in rectangular microchannels driven by capillary forces and gravity. Int Comm Heat Mass Transf 34:186–196

Keane RD, Adrian RJ (1992) Theory of cross-correlation analysis of PIV images. Appl Sci Res 49:191–215

Kim JS, Sung J, Kim S, Kim JS (2008) PIV measurements on the change of the three-dimensional wake structures by an air spoiler of a road vehicle. J Vis 11:45–54

Lee SH, Sung J, Kim EK (2010) Dynamic flow measurements of capillary underfill through a bump array in flip chip package. Microelectron Reliab 50:2078–2083

Meinhart CD, Wereley ST, Santiago JG (1999) PIV measurements of a microchannel flow. Exp Fluids 27:414–419

Nguyen L, Quentin C, Fine P, Cobb B, Bayyuk S, Yang H, Bidstrup-Allen SA (1999) Underfill of flip chip on laminates: simulation and validation. IEEE Trans Compon Package Technol 22:168–176

Sung J, Yoo JY (2001) Three-dimensional phase-averaging of time-resolved PIV measurement data. Meas Sci Technol 12:655–662

Tummala RR (2001) Fundamentals of microsystems packaging. McGrew-Hill, Singapore

Wan JW, Zhang WJ, Bergstrom DJ (2005) An analytical model for predicting the underfill flow characteristics in flip-chip encapsulation. IEEE Trans Adv Packaging 28:481–487

Wan JW, Zhang WJ, Bergstrom DJ (2008) Experimental verification of models for underfill flow driven by capillary forces in flip-chip packaging. Microelectron Reliab 48:425–430

Wan JW, Zhang WJ, Bergstrom DJ (2009) Numerical modeling for the underfill flow in flip-chip packaging. IEEE Trans Compon Package Technol 32:227–233

Wang J (2002) Underfill of flip chip on organic substrate: viscosity, surface tension, and contact angle. Microelectron Reliab 42:293–299

Wang J (2005) Flow time measurements for underfills in flip-chip packaging. IEEE Trans Compon Package Technol 28:366–370

Washburn EW (1921) The dynamics of capillary flow. Phys Rev 17:273–283

Young WB (2004) Capillary impregnation into cylinder banks. J Coll Interface Sci 273:576–580

Young WB, Yang WL (2002) The effect of solder bump pitch on the underfill flow. IEEE Trans Adv Packaging 25:537–542

Acknowledgments

This research was supported by Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education, Science and Technology (2010-0009054).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, Y.B., Sung, J. & Lee, M.H. Micro-PIV measurements of capillary underfill flows and effect of bump pitch on filling process. J Vis 14, 237–248 (2011). https://doi.org/10.1007/s12650-011-0073-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12650-011-0073-2