Abstract

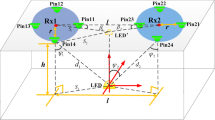

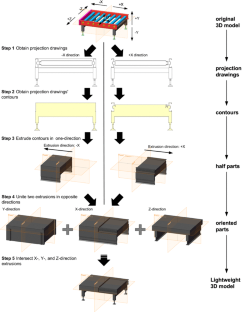

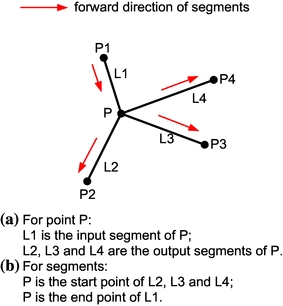

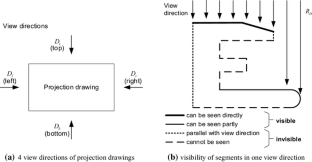

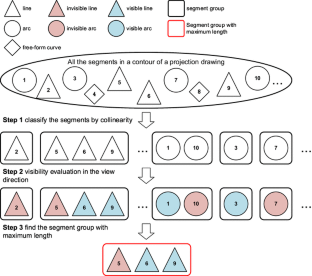

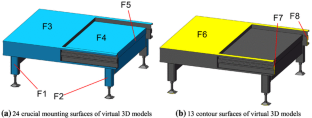

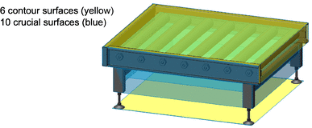

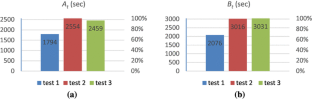

Because of the large quantity of three-dimensional (3D) models and the manual operation process used for their virtual assembly, production line assembly design is time consuming and cannot readily meet the requirements of normalization. To address these problems, we propose a rapid virtual assembly approach based on the smart recognition of assembly features and present a system based on this concept. A 3D-two-dimensional (2D)-3D assembly feature recognition mode is proposed. The 3D models are first standardized using a standardization algorithm. The standardized 3D models are subsequently divided into six half parts, and each half part is projected into the coordinate plane to obtain its 2D projection drawing. The contours of the 2D projection drawings are obtained via a contour-recognition algorithm, and segments in contours are classified into different groups according to collinearity. A lightweight 3D model of the original 3D model is created through a series of Boolean operations. Assembly features can be obtained by matching the lightweight 3D model with the original 3D model. The recognized assembly features are used in the rapid assembly system to perform the assembly, and the constraints among these features are automatically added when two models are in proximity. Three comparison tests are conducted, and the results show that the system simplifies the assembly process, greatly increases the assembly design efficiency of the production line, and simultaneously reduces the workload and operational complexity.

Similar content being viewed by others

References

Fan X, Tian L, He Q, Liu K (2015) Assembly-Design-Oriented Semantic Modeling and Assembly Configuration Simulation in Virtual Environment. In: ASME 2015 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Boston, USA

Frei R, Pereira N, Belo J, Barata J, Di Marzo Serugendo G (2010a) Implementing self-organisation and self-management in evolvable assembly systems. In: To appear in IEEE International symposium on industrial electronics (ISIE), Bari, Italy

Frei R, Serugendo GDM, Șerbănuță TF (2010b) Ambient intelligence in self-organising assembly systems using the chemical reaction model. J Ambient Intell Humaniz Comput 1(3):163–184

Frei R, Şerbănuţă TF, Serugendo GDM (2014) Self-organising assembly systems formally specified in Maude. J Ambient Intell Humaniz Comput 5(4):491–510

Gonzalez-Badillo G, Medellin-Castillo H, Lim T, Ritchie J, Garbaya S (2014) The development of a physics and constraint-based haptic virtual assembly system. Assembly Autom 34(1):41–55

Guo Q, Tang H, Guo S, Li Y, Zhang J (2015) An automatic assembly CAD system of plastic profile calibrating die based on feature recognition. Int J Adv Manuf Technol (85)9:2577–2587

Han P, Zhao G (2017) Line-based initialization method for mobile augmented reality in aircraft assembly. Visual Comput 33(9):1185–1196

Holland WV, Bronsvoort WF (2000) Assembly features in modeling and planning. Robot Comput Integr Manufac 16(4):277–294

Huang J, Fukuda T, Matsuno T (2008) Model-based intelligent fault detection and diagnosis for mating electric connectors in robotic wiring harness assembly systems. IEEE/ASME Trans Mechatron 13(1):86–94

Huang J, Di P, Fukuda T, Matsuno T (2010) Robust model-based online fault detection for mating process of electric connectors in robotic wiring harness assembly systems. IEEE Trans Control Syst Technol 18(5):1207–1215

Kim H, Cha M, Mun D (2017) Shape distribution-based approach to comparing 3D CAD assembly models. J Mech Sci Technol 31(12):5627–5638

Li M, Hashimoto K (2017) Curve set feature-based robust and fast pose estimation algorithm. Sensors 17(8):1782

Li Z, Zhou X, Liu W (2017) Hierarchical representation and similarity assessment for reuse of sheet metal parts. Proc Inst Mech Eng, Part B: J Eng Manuf 232(2):328–338

Lingam R, Prakash O, Belk JH, Reddy NV (2017) Automatic feature recognition and tool path strategies for enhancing accuracy in double sided incremental forming. Int J Adv Manuf Technol 88(5–8):1639–1655

Liu W, Zhou X, Zhang X, Niu Q (2015) Three-dimensional (3D) CAD model lightweight scheme for large-scale assembly and simulation. Int J Comput Integr Manuf 28(5):520–533

Salem AA, Abdelmaguid TF, Wifi AS, Elmokadem A (2017) Towards an efficient process planning of the V-bending process: an enhanced automated feature recognition system. Int J Adv Manuf Technol 91(9–12):4163–4181

Tao F, Qi Q (2017) New IT driven service-oriented smart manufacturing: framework and characteristics. IEEE Trans Syst, Man, Cybern: Syst

Tao F, Zhang M (2017) Digital twin shop-floor: a new shop-floor paradigm towards smart manufacturing. IEEE Access 5:20418–20427

Tao F, Cheng J, Qi Q, Zhang M, Zhang H, Sui F (2017a) Digital twin-driven product design, manufacturing and service with big data. Int J Adv Manuf Technol, 1–14

Tao F, Zhang M, Cheng J, Qi Q (2017b) Digital twin workshop: a new paradigm for future workshop. Comput Integr Manuf Syst 23(1):1–9

Wang P, Li Y, Yu L, Zhang J, Xu Z (2016) A novel assembly simulation method based on semantics and geometric constraint. Assembly Autom 36(1):34–50

Wang Y, Zhang S, Yang S, He W, Bai X (2018) Mechanical assembly assistance using marker-less augmented reality system. Assembly Autom 38(1):77–87

Xiao H, Li Y, Yu JF, Cheng H (2014a) Dynamic assembly simplification for virtual assembly process of complex product. Assembly Autom 34(1):1–15

Xiao H, Li Y, Yu J, Zhang J, Tang W (2014b) Dynamic assembly simplification for virtual assembly process of complex product in cloud computing environment. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture 228(10): 1198–1213

Xiao H, Duan Y, Zhang Z (2018) Mobile 3D assembly process information construction and transfer to the assembly station of complex products. Int J Comput Integr Manuf 31(1):11–26

Yu JF, Xiao H, Zhang J, Cheng H, Xin B (2013) CAD model simplification for assembly field. Int J Adv Manuf Technol 68(9–12):2335–2347

Zhang J, Xu Z, Li Y, Jiang S (2015) Framework for the integration of assembly modeling and simulation based on assembly feature pair. Int J Adv Manuf Technol 78(5–8):765–780

Zhang M, Chen S, Shu Z, Xin SQ, Zhao J, Jin G, Zhang R, Beyerer J (2017) Fast algorithm for 2D fragment assembly based on partial EMD. Visual Comput 33(12):1601–1612

Acknowledgements

This research was financially supported by the Natural Science Foundation of Hubei Province, China (No. 2015CFA115); the National Key Research Plan, China (No. 2016YFB1101701); and Science and Technology Support Program of Hubei Province, China (No. 2015BAA058).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sheng, B., Yin, X., Zhang, C. et al. A rapid virtual assembly approach for 3D models of production line equipment based on the smart recognition of assembly features. J Ambient Intell Human Comput 10, 1257–1270 (2019). https://doi.org/10.1007/s12652-018-0753-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12652-018-0753-z