Abstract

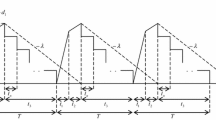

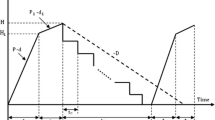

This paper considers an economic manufacturing quantity (EMQ) model for defective products with imperfect production processes and rework, in which the setup cost is logarithmic function of capital investment. In this study, fixed quantity multiple installments of the finished batch are delivered to customers at a fixed interval of time. We also consider three types of continuous probabilistic defective function to find the associated cost. The way our basic business operations like decision making, marketing strategies, financial management, etc. are done are being reformed with the use of computers and mathematics. In view of that the mathematical modeling and computational algorithm are employed in this study for optimizing the replenishment lot-size and setup cost simultaneously with the objective of minimizing total cost of the EMQ system. The long-run average cost function is derived, its convexity is proved via differential calculus. A computer code using the software Matlab is developed to derive the optimal solution and present numerical examples to illustrate the model.

Similar content being viewed by others

References

Aderohunmu R, Mobolurin A, Bryson N (1995) Joint vendor buyer policy in JIT manufacturing. J Oper Res Soc 46:375–385

Affisco JF, Paknejad MJ, Nasri F (2002) Quality improvement and setup reduction in the joint economic lot size model. Eur J Oper Res 142:497–508

Annadurai K, Uthayakumar R (2010) Controlling setup cost in (Q, r, L) inventory model with defective items. Appl Math Model 34:1418–1427

Bera UK, Maiti MK, Maiti M (2012) Inventory model with fuzzy lead-time and dynamic demand over finite time horizon using a multi-objective genetic algorithm. Comput Math Appl 64:1822–1838

Cardenas-Barron LE, Sarkar B, Trevino-Garza G (2013) An improved solution to the replenishment policy for the EMQ model with rework and multiple shipments. Appl Math Model 37:5549–5554

Chen YC (2013) An optimal production and inspection strategy with preventive maintenance error and rework. J Manuf Syst 32:99–106

Chiu YSP, Chen KK, Cheng FT, Wu MF (2010) Optimization of the finite production rate model with scrap, rework and stochastic machine breakdown. Comput Math Appl 59:919–932

Chiu YSP, Liu SC, Chiu CL, Chang HH (2011) Mathematical modeling for determining the replenishment policy for EMQ model with rework and multiple shipments. Math Comput Model 54:2165–2174

Chung KJ (2011) The economic production quantity with rework process in supply chain management. Comput Math Appl 62:2547–2550

Chung KJ (2012) The integrated inventory model with the transportation cost and two-level trade credit in supply chain management. Comput Math Appl 64:2011–2033

Chung CJ, Wee HM (2008) An integrated production–inventory deteriorating model for pricing policy considering imperfect production, inspection panning and warranty-period-and stock-level-dependent demand. Int J Syst Sci 9:823–837

Coates ER (1996) Manufacturing setup cost reduction. Comput Ind Eng 31:111–114

Crdenas-Barrn LE (2010) An easy method to derive EOQ and EPQ inventory models with backorders. Comput Math Appl 59:948–952

Das D, Roy A, Kar S (2011) A volume flexible economic production lot-sizing problem with imperfect quality and random machine failure in fuzzy-stochastic environment. Comput Math Appl 61:2388–2400

Diaby M, Cruz JM, Nsakanda AL (2013) Shortening cycle times in multi-product, capacitated production environments through quality level improvements and setup reduction. Eur J Oper Res 228:526–535

Dutta P, Chakraborty D, Roy AR (2007) An inventory model for single-period products with reordering opportunities under fuzzy demand. Comput Math Appl 53:1502–1517

Glock CH, Grosse EH, Ries JM (2014) The lot sizing problem: a tertiary study. Int J Prod Econ 155:39–51

Goyal SK (1977) Integrated inventory model for a single supplier single customer problem. Int J Prod Res 15:107–111

Goyal SK, Huang CK, Chen HK (2003) A simple integrated production policy of an imperfect item for vendor and buyer. Prod Plan Control 14:596–602

Hadley G, Whitin TM (1963) Inventory systems. Prentice Hall, Upper Saddle River

Haji R, Haji A, Sajasifar M, Zolfaghari S (2008) Lot sizing with non-zero setup times for rework. J Syst Sci Syst Eng 17:230–240

Harris FW (1913) How many parts to make at once. Fact Mag Manag 10:135–136 (reprinted in Operations Research 38(1990):947–950)

Hayek PA, Salameh MK (2001) Production lot sizing with the reworking of imperfect quality items produced. Prod Plan Control 12:584–590

Hillier FS, Lieberman GJ (2001) Introduction to operations research. McGraw Hill, New York

Hong JD, Hayya JC (1995) Joint investment in quality improvement and setup reduction. Comput Oper Res 22:567–574

Hou KL (2007) An EPQ model with setup cost and process quality as functions of capital expenditure. Appl Math Model 31:10–17

Khan M, Jaber MY, Abdul-Rahim A (2014) An integrated supply chain model with errors in quality inspection and learning in production. Omega 42:16–24

Lin H-D, Chiu Y-SP, Ting C-K (2008) A note on optimal replenishment policy for imperfect quality EMQ model with rework and backlogging. Comput Math Appl 56:2819–2824

Lin LC, Hou KL (2005) An inventory system with investment to reduce yield variability and setup cost. J Oper Res Soc 56:67–74

Mahata GC, Goswami A, Gupta DK (2005) A joint economic-lot-size model for purchaser and vendor in fuzzy sense. Comput Math Appl 50:1767–1790

Maity K, Maiti M (2008) A numerical approach to a multi-objective optimal inventory control problem for deteriorating multi-items under fuzzy inflation and discounting. Comput Math Appl 55:1794–1807

Porteus EL (1985) Investing in reduced setups in the EOQ model. Manag Sci 31:998–1010

Salameh MK, Jaber MY (2000) Economic production quantity model for items with imperfect quality. Int J Prod Econ 64:59–64

Sarkar B (2013) A production–inventory model with probabilistic deterioration in two-echelon supply chain management. Appl Math Model 37:3138–3151

So KC, Tang CS (1995) Optimal operating policy for a bottleneck with random rework. Manag Sci 41:620–636

Taheri-Tolgari J, Mirzazadeh A, Jolai F (2012) An inventory model for imperfect items under inflationary conditions with considering inspection errors. Comput Math Appl 63:1007–1019

Taleizadeh AA, Pentico DW, Jabalameli MS, Aryanezhad M (2013) An EOQ model with partial delayed payment and partial backordering. Omega 41:354–368

Widyadana GA, Wee HM (2010) Revisiting lot sizing for an inventory system with product recovery. Comput Math Appl 59:2933–2939

Xie J, Dong J (2002) Heuristic genetic algorithms for general capacitated lot-sizing problems. Comput Math Appl 44:263–276

Acknowledgments

The authors would like to acknowledge the anonymous reviewer for his encouragement and constructive comments in revising the paper. The first author is grateful to the Mepco Schlenk Engineering College, Sivakasi 626 005, Virudhunagar, Tamilnadu, India, for the infrastructural assistance to carry out the research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Priyan, S., Uthayakumar, R. Setup cost reduction EMQ inventory system with probabilistic defective and rework in multiple shipments management. Int J Syst Assur Eng Manag 8, 223–241 (2017). https://doi.org/10.1007/s13198-016-0418-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13198-016-0418-2