Abstract

Conventionally, steady state design for distillation column is often completed before dynamics and control issues are considered. The aim of this paper is to use the design issues as a tool to improve dynamic behavior of binary distillation column. The idea is augmenting the liquid holdup in the feed plate through a middle vessel. The degree of interactions between the loops are examined for five well known control schemes by considering different quantities of liquid holdup in the feed plate. Simulation results show that augmenting the hold-up in the feed plate will lead to minimize the interactions between the loops in all cases particularly for DV control scheme where a total decoupling is achieved.

Similar content being viewed by others

References

An Y, Li W, Huang S, Ma J, Shen C, Xu C (2015) Design and optimization of energy saving of extractive distillation process by combining preconcentration column and extractive distillation column. Chem Eng Sci 135:166–178

Barolo M, Guarise BG (1996) Some issues in the design and operation of a batch distillation column with a middle vessel. Comput Chem Eng 20:S37–S42

Deeptanshu D, Halvorsen I, Skogestad S (2011) Control structure for optimal operation for 4 product thermally coupled column. AIChE Spring National Meeting, March 13–17, 2011, Chicago, Illinois, USA

Dorf RC, Bishop RH (2011) Modern control systems, 12th edn. Prentice Hall, New York

Esref E (2003) Dynamic consistency relations in process modeling. AIChE J 49(8):2224–2227

Garrido J, Vazquez F, Manilla F (2012) Centralzed multivariable decoupling control by simplified decoupling. J Process Control 22:1044–1062

Halvorsen I, Skogestad S (2000) Distillation theory. Encyclopedia of separation science. Academic Press, Cambridge, pp 1117–1134

Hori ES, Skogestad S (2007) Selection of control structure and temperature location for two product distillation column. IChemE 85(A3):293–306

Huang H, Ohshima M, Hashimoto L (1994) Dynamic interaction and multiloop control system design. J Process Control 4(1):15–27

Karami G, Amidpour M, Heidari B, Salehi RG (2015) Distillation column controllability analysis through heat pump integration. Chem Eng Process 97:23–37

Khelassi A (1991) Analysis and assessment of interaction in process control system. Ph.D. Thesis, University of Nottingham, Nottingham, UK

Khelassi A, Bendib R, Benhalla A (2012) Configurations of binary distillation column for optimal control. UKACC international conference on control Cardiff-UK. IEEE Xplorer, pp 793–797

King CJ (2013) Separation process, 2nd edn. Dover Publication, Mineola

Kurt EH, Kurt W (1990) Control structures for disturbance rejection and decoupling of distillation column. AIChE J 36(7):1107–1113

Lundström P, Skogestad S (1995) Opportunities and difficulties with (5 × 5) distillation control. J Process Control 5:249–261

Luo X, Liu Y, Xu F (2014) Interaction analysis and decomposition principle for control structure design of large scale systems. Chin J Chem Eng 22(1):59–71

Luyben W (1990) Process modeling, simulation and control for chemical engineers, 2nd edn. McGraw Hill, New York

Luyben W (1992) Practical distillation control. Van Nostrand Reinhold, New York

McAvoy T, Arkum Y, Robinson D, Schnelle PD (2003) A new approach to defining a dynamic relative gain. Control Eng Pract 11:907–914

Nakaiwa M, Hung K, Endo A, Ohmori T, Akiya T, Takamatsu T (2003) Internally heat integrated distillation column a review. Trans IChemE 81, part A:162–177

Nandong J, Zang Z (2014) Multiloop design of multiscale controllers for multivariable processes. J Process Control 24(2014):600–612

Ogata K (2010) Modern control engineering, 5th edn. Prentice Hall, Upper Saddle River

Perry H, Green D (2007) Perry’s chemical engineer’ handbook, 8th edn. Mc Graw Hill, New York

Porru M, Baratti R, Alvarez J (2015) Energy saving through control in an industrial multicomponent distillation column. IFAC Pap Online 48–8(2015):1139–1143

Potts AS, Massaro LC, Garcia C (2015) Detection of decoupled input/output pairs in multivariable systems. ISA Trans 55:195–207

Shandeh H, Ivakapour J, Kasiri N (2014) Feasibility study of heat integrated distillation columns using rigorous optimization. Energy 74:662–674

Shinskey F (1984) Distillation control, 2nd edn. Mc Graw Hill, New York

Shinskey F (1996) Process control systems, 4th edn. Mc Graw Hill, New York

Skogestad S (1997) Dynamics and control of distillation columns. Trans IChemE 75, part A:539–562

Skogestad S, Morari M (1987) Control configuration selection for distillation column. AIChE J 33(10):1620–1635

Skogestad S, Postlethwaite I (2007) Multivariable feed back control analysis and design, 2nd edn. Wiley, Hoboken

Sodré C, Wilson J, Jones W (2000) Practical evaluation of hold-up for passive decoupling in distillation column. Braz J Chem Eng 17(4–7):1003–1014

Sujatha V, Panda RC (2013) Control configuration selection for multi input multi output processes. J Process Control 23:1567–1574

Xiong Q, Cai W, He M (2005) A practical loop pairing criterion for multivariable processes. J Process Control 15(2005):741–746

Zumoffen D, Gonzalo M, Basualdo M (2013) Improvements of multivariable control strategies tested on the Petlyuk distillation column. Chem Eng Sci 93:292–306

Author information

Authors and Affiliations

Corresponding author

Appendix: The used column

Appendix: The used column

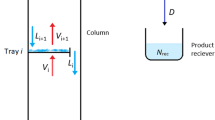

It consists of seven plates, a reboiler, and a condenser. The column separates a mixture of Benzene–Toluene. The feed is entering at plates 4 numbering from the base. Measurements are the compositions of liquid on plate 7 and reboiler. The manipulated variables are reflux, distillate flow, bottom flow, and reboiler steam valve position. Vapor flow into the column responds quickly to changes in steam valve position. The linear model for this column in state space representation given by

Rights and permissions

About this article

Cite this article

Bendib, R., Bentarzi, H. Contribution to improve the dynamic control of a binary distillation column. Int J Syst Assur Eng Manag 8 (Suppl 2), 663–675 (2017). https://doi.org/10.1007/s13198-016-0503-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13198-016-0503-6