Abstract

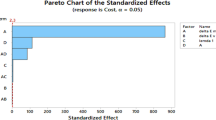

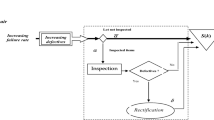

Production systems are exposed to machine failures and in most of them, buffer stocks are built between machines to guarantee that demands will be supplied during the interruptions because of breakdowns or periodic preventive maintenance (PM) actions. Also determination of the optimal maintenance policy in a production line is critical and it leads to provide a reliable system at lowest average total cost per time unit (comprising maintenance, quality and inventory costs). This is achieved by considering thresholds for nonconforming units and comparing with the proportion of produced nonconforming units and decides whether to undertake maintenance actions or not. The objective of this study is to integrating three aspects of quality, maintenance and production in operational units. In order to show the capability and effectiveness of the proposed approach, an operational unit consists of two machines is considered as a case study. The problem is modeled by simulation and the values of buffer stocks and nonconforming unit thresholds are determined to obtain the minimum average total cost using Taguchi method. Different rejection rates and buffer stocks values were given to the model as inputs in order to find the minimum average total cost which can satisfy the demand.

Similar content being viewed by others

References

Alfares HK, Khursheed SN, Noman SM (2005) Integrating quality and maintenance decisions in a production-inventory model for deteriorating items. Int J Prod Res 43(5):899–911

Ayed S, Sofiene D, Nidhal R (2012) Joint optimization of maintenance and production policies considering random demand and variable production rate. Int J Prod Res 50(23):6870–6885

Azadeh A, Sheikhalishahi M, Firoozi M, Khalili SM (2013) An integrated multi-criteria Taguchi computer simulation-DEA approach for optimum maintenance policy and planning by incorporating learning effects. Int J Prod Res 51(18):5374–5385

Azadeh A, Sheikhalishahi M, Khalili SM, Firoozi M (2014) An integrated fuzzy simulation–fuzzy data envelopment analysis approach for optimum maintenance planning. Int J Comput Integrated Manuf 27(2):181–199

Azadivar F (1999) Simulation optimization methodologies. In: Proceedings of the 31st conference on winter simulation: simulation—a bridge to the future ACM, vol 1, pp 93–100

Ben-Daya M (2002) The economic production lot-sizing problem with imperfect production processes and imperfect maintenance. Int J Prod Econ 76(3):257–264

Boschian V, Rezg N, Chelbi A (2009) Contribution of simulation to the optimization of maintenance strategies for a randomly failing production system. Eur J Oper Res 197(3):1142–1149

Chelbi A, Ait-Kadi D (2004) Analysis of a production inventory system with randomly failing production unit submitted to regular preventive maintenance. Eur J Oper Res 156(3):712–718

Chen YC (2013) Optimal production and inspection strategy with inspection time and reworking for a deteriorating process. Int J Oper Res 10(3):123–133

Colledani M, Tolio T (2012) Integrated quality, production logistics and maintenance analysis of multi-stage asynchronous manufacturing systems with degrading machines. CIRP Ann Manuf Technol 61(1):455–458

Dhouib K, Gharbi A, Ben Aziza MN (2012) Joint optimal production control/preventive maintenance policy for imperfect process manufacturing cell. Int J Prod Econ 137(1):126–136

Fu MC, Glover FW, April J (2005) Simulation optimization: a review, new developments, and applications. In: 2005 Proceedings of the winter simulation conference. IEEE, 13 pp

Huang BS, Chiu HN (1995) The quality management of the imperfect production process under two monitoring policies. Int J Qual Reliab Manag 12(3):19–31

Makis V, Fung J (1995) Optimal preventive replacement, lot sizing and inspection policy for a deteriorating production system. J Qual Maint Eng 1(4):41–55

Meller RD, Kim DS (1996) The impact of preventive maintenance on system cost and buffer size. Eur J Oper Res 95(3):577–591

Rahim MA, Ben-Daya M (2001) Joint determination of production quantity, inspection schedule, and quality control for an imperfect process with deteriorating products. J Oper Res Soc 1370–1378

Rezg N, Xie X, Mati Y (2004) Joint optimization of preventive maintenance and inventory control in a production line using simulation. Int J Prod Res 42(10):2029–2046

Rezg N, Chelbi A, Xie X (2005) Modeling and optimizing a joint inventory control and preventive maintenance strategy for a randomly failing production unit: analytical and simulation approaches. Int J Comput Integr Manuf 18(2–3):225–235

Rezg N, Dellagi S, Chelbi A (2008) Joint optimal inventory control and preventive maintenance policy. Int J Prod Res 46(19):5349–5365

Ribeiro MA, Silveira JL, Qassim RY (2007) Joint optimisation of maintenance and buffer size in a manufacturing system. Eur J Oper Res 176(1):405–413

Safizadeh MH (1990) Optimization in simulation: current issues and the future outlook. Nav Res Logist 37(6):807–825

Salameh MK, Ghattas RE (2001) Optimal just-in-time buffer inventory for regular preventive maintenance. Int J Prod Econ 74(1):157–161

Sana SS (2012) Preventive maintenance and optimal buffer inventory for products sold with warranty in an imperfect production system. Int J Prod Res 50(23):6763–6774

Sheikhalishahi M (2014) An integrated simulation data envelopment analysis approach for maintenance activities planning. Int J Comput Integr Manuf 27(9):858–868

Sheikhalishahi M, Ebrahimipour V, Farahani MH (2014) An integrated GA-DEA algorithm for determining the most effective maintenance policy for ak-out-of-n problem. J Intell Manuf 25(6):1455–1462

Suliman S, Jawad SH (2012) Optimization of preventive maintenance schedule and production lot size. Int J Prod Econ 137(1):19–28

Taguchi G, Yokoyama Y (1993) Taguchi methods: design of experiments, vol 4. Am Suppl Inst

Tseng ST, Yeh RH, Ho WT (1998) Imperfect maintenance policies for deteriorating production systems. Int J Prod Econ 55(2):191–201

Zequeira RI, Valdes JE, Berenguer C (2008) Optimal buffer inventory and opportunistic preventive maintenance under random production capacity availability. Int J Prod Econ 111(2):686–696

Acknowledgements

The authors are grateful for the valuable and useful comments by the respected reviewers. This study was supported by a grant from University of Tehran (Grant No. 8106013/1/21). The authors are grateful for the support provided by the College of Engineering, University of Tehran, Iran.

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix 1

See Table 6.

Appendix 2

See Table 7.

Appendix 3

Table 8.

Rights and permissions

About this article

Cite this article

Azadeh, A., Sheikhalishahi, M., Mortazavi, S. et al. Joint quality control and preventive maintenance strategy: a unique taguchi approach. Int J Syst Assur Eng Manag 8, 123–134 (2017). https://doi.org/10.1007/s13198-016-0536-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13198-016-0536-x