Abstract

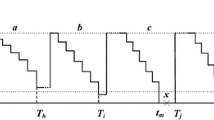

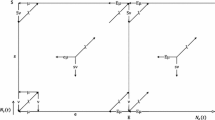

Aiming at multi-echelon inventory optimization of spare parts, the process of equipment support under preemptive maintenance and non-preemptive maintenance were analyzed. The support time of spare parts in each maintenance sites was calculated and a model of expected backorder was established. The marginal effect algorithm was utilized to calculate the maintenance priority assignment and inventory policy of spare parts. Finally, through a numerical example, the inventory project of spare parts obtained by the proposed model can greatly reduce the cost of the spare parts while ensuring the availability of the equipment, and which can improve the military and economic benefits of the equipment support commendably.

Similar content being viewed by others

References

Costantino F, di Gravio G, Tronci M (2013) Multi-echelon, multi-indenture spare parts inventory control subject to system availability and budget constraints. Reliab Eng Syst Saf 119:95–101

Francesco C, Giulio DG, Massimo T (2013) Multi-echelon, multi-indenture spare parts inventory control subject to system availability and budget constraints. Reliab Eng Syst Saf 19:95–101

Levner E, Perlman Y, Cheng TCE, Levner I (2011) A network approach to modeling the multi-echelon spare-part inventory system with backorders and interval-valued demand. Int J Prod Econ 132(1):43–51

Liu C-F (2011) Research on manufacturing supply chain multi-echelon inventory optimization based on centre strategy. Manuf Autom 11:35–37

Olsson F (2010) An inventory model with unidirectional lateral transshipments. Eur J Oper Res 200:725–732

Paterson C, Kiesmuller G, Teunter R et al (2011) Inventory models with lateral transshipments: a review. Eur J Oper Res 210(2):125–136

Ruan M-Z, Li Q-M, Huang A-L et al (2012) Inventory control of multi-echelon maintenance supply under finite repair channel constraint. Acta Aeronautica et Astronautica Sinica 33(11):2018–2027

Samouei P, Kheirkhah AS, Fattahi P (2015) A network approach modeling of multi-echelon spare-part inventory system with backorders and quantity discount. Ann Oper Res 226(1):551–563

Sherbrooke CC (1968) METRIC: a multi-echelon technique for recoverable item control. Oper Res 16(1):122–141

Sherbrooke CC (2006) Optimal inventory modeling of systems: multi-echelon techniques. Springer, Amsterdam

Sleptchenko A, van der Heijden MC, van Harten A (2002) Effects of finite repair capacity in multi-echelon, multi-indenture service part supply systems. Int J Prod Econ 79(3):209–230

Sleptchenko A, van der Heijden MC, van Harten A (2005) Using repair priorities to reduce stock investment in spare part networks. Eur J Oper Res 163:733–750

Tiacci L, Saetta S (2011) Reducing the mean supply delay of spare parts using lateral transshipments policies. Int J Prod Econ 133(1):182–191

Topan E, Bayindir ZP (2012) Multi-item two-echelon spare parts inventory control problem with batch ordering in the central warehouse under compound Poisson demand. J Oper Res Soc 63(8):1143–1152

Topan E, Bayindir ZP, Tan T (2010) An exact solution procedure for multi-item two-echelon spare parts inventory control problem with batch ordering in the central warehouse. Oper Res Lett 38(5):454–461

Xu L, Li Q-M, Ruan M-Z (2014) Support project optimiza-tion for warship formation with finite repair capacity. Syst Eng Electron 36(11):2226–2232

Zhang G-Y, Li Q-M, Guo X (2012) Modeling for repairable spare parts in multi-location inventory system with lateral transshipments. Syst Eng Electron 34(7):1424–1429

Zhang G-Y, Li Q-M, Ge E-S (2013) Modeling and optimization of multi-location inventory lateral transshipment system of repairable spare parts. J Naval Univ Eng 25(5):52–58

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, Yk., Gao, Q., Su, Xb. et al. Research on optimization of spare parts inventory policy considering maintenance priority. Int J Syst Assur Eng Manag 9, 1336–1345 (2018). https://doi.org/10.1007/s13198-018-0748-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13198-018-0748-3