Abstract

Master production schedules (MPS) and Material requirements planning (MRP) are two important planning modules in the production planning system. In this paper, a new fuzzy credibility-based double-sided chance-constrained programming (FCDCP) model is proposed for the capacitated MPS/MRP integrated programming problem under complex uncertainty. The proposed model supports simultaneous lot sizing and scheduling decisions and can deal with uncertainty presented as fuzziness in both right-hand and left-hand sides of constraints. To tackle the FCDCP model, the corresponding defuzzification methods based on credibility measure are proposed for transforming the fuzzy MPS/MRP integrated programming model into a crisp equivalent mixed-integer programming model. When decision-makers decide on MPS/MRP integrated programming problem, the optimal lot sizing and scheduling solutions from the FCDCP model can not only provide an effective method for production planners to deal with the uncertainty in the production system, making the production plan more reasonable and accurate, but it can also help decision-makers obtain the optimal production plans and determine the best allocation of production resources, effectively reducing the total cost of the production system. Finally, an industrial example from a transmission manufacturer is provided to show the applicability and flexibility of the model.

Similar content being viewed by others

References

Ramezanian, R., Saidi-Mehrabad, M., Fattahi, P.: MIP formulation and heuristics for multi-stage capacitated lot-sizing and scheduling problem with availability constraints. J. Manuf. Syst. 32(2), 392–401 (2013)

Körpeoğlu, E., Yaman, H., Aktürk, M.S.: A multi-stage stochastic programming approach in master production scheduling. Eur. J. Oper. Res. 213(1), 166–179 (2011)

Ramezanian, R., Saidi-Mehrabad, M.: Hybrid simulated annealing and MIP-based heuristics for stochastic lot-sizing and scheduling problem in capacitated multi-stage production system. Appl. Math. Model. 37(7), 5134–5147 (2013)

De Smet, N., Minner, S., Aghezzaf, E.-H., et al.: A linearisation approach to the stochastic dynamic capacitated lotsizing problem with sequence-dependent changeovers. Int. J. Prod. Res. 58(16), 4980–5005 (2020)

Guillaume, R., Thierry, C., Zieliński, P.: Robust material requirement planning with cumulative demand under uncertainty. Int. J. Prod. Res. 55(22), 6824–6845 (2017)

Mohammadi, M., Esmaelian, M., Atighehchian, A.: Design of mathematical models for the integration of purchase and production lot-sizing and scheduling problems under demand uncertainty. Appl. Math. Model. 84, 1–18 (2020)

Ozturk, C., Ornek, A.M.: Capacitated lot sizing with linked lots for general product structures in job shops. Comput. Ind. Eng. 58(1), 151–164 (2010)

Ríos-Solís, Y.Á., Ibarra-Rojas, O.J., Cabo, M., et al.: A heuristic based on mathematical programming for a lot-sizing and scheduling problem in mold-injection production. Eur. J. Oper. Res. 284(3), 861–873 (2020)

Rodoplu, M., Arbaoui, T., Yalaoui, A.: A fix-and-relax heuristic for the single-item lot-sizing problem with a flow-shop system and energy constraints. Int. J. Prod. Res. 58, 1–21 (2019)

Buschkühl, L., Sahling, F., Helber, S., et al.: Dynamic capacitated lot-sizing problems: a classification and review of solution approaches. OR Spectr. 32(2), 231–261 (2010)

Tempelmeier, H., Buschkuhl, L.: A heuristic for the dynamic multi-level capacitated lotsizing problem with linked lotsizes for general product structures. OR Spectr. 31(2), 385–404 (2009)

Díaz-Madroñero, M., Mula, J., Jiménez, M., et al.: A rolling horizon approach for material requirement planning under fuzzy lead times. Int. J. Prod. Res. 55(8), 2197–2211 (2017)

Fandel, G., Stammen-Hegene, C.: Simultaneous lot sizing and scheduling for multi-product multi-level production. Int. J. Prod. Econ. 104(2), 308–316 (2006)

Ke, G., Chen, R.-S., Chen, Y.-C., et al.: Using ant colony optimisation for improving the execution of material requirements planning for smart manufacturing. Enterp. Inf. Syst., 1–23 (2020)

Ramezanian, R., Rahmani, D., Barzinpour, F.: An aggregate production planning model for two phase production systems: solving with genetic algorithm and tabu search. Expert Syst. Appl. 39(1), 1256–1263 (2012)

Suerie, C., Stadtler, H.: The capacitated lot-sizing problem with linked lot sizes. Manag. Sci. 49(8), 1039–1054 (2003)

Lang, J.C., Shen, Z.J.M.: Fix-and-optimize heuristics for capacitated lot-sizing with sequence-dependent setups and substitutions. Eur. J. Oper. Res. 214(3), 595–605 (2011)

Wang, S., Kurz, M., Mason, S.J., et al.: Two-stage hybrid flow shop batching and lot streaming with variable sublots and sequence-dependent setups. Int. J. Prod. Res. 57(22), 6893–6907 (2019)

Żurowski, M., Gawiejnowicz, S.: Scheduling preemptable position-dependent jobs on two parallel identical machines. Comput. Ind. Eng. 132, 373–384 (2019)

Kang, J.: Capacitated lot-sizing problem with sequence-dependent setup, setup carryover and setup crossover. Processes 8(7), 785 (2020)

Ramezanian, R., Saidi-Mehrabad, M.: Multi-product unrelated parallel machines scheduling problem with rework processes. Sci. Iran. 19(6), 1887–1893 (2012)

Tempelmeier, H., Copil, K.: Capacitated lot sizing with parallel machines, sequence-dependent setups, and a common setup operator. OR Spectr. 38(4), 819–847 (2016)

Mula, J., Poler, R., García-Sabater, J.P., et al.: Models for production planning under uncertainty: a review. Int. J. Prod. Econ. 103(1), 271–285 (2006)

Mula, J., Poler, R., Garcia-Sabater, J.P.: Material Requirement Planning with fuzzy constraints and fuzzy coefficients. Fuzzy Sets Syst. 158(7), 783–793 (2007)

Randa, A.C., Doğru, M.K., Iyigun, C., et al.: Heuristic methods for the capacitated stochastic lot-sizing problem under the static-dynamic uncertainty strategy. Comput. Oper. Res. 109, 89–101 (2019)

Tarim, S.A., Kingsman, B.G.: The stochastic dynamic production/inventory lot-sizing problem with service-level constraints. Int. J. Prod. Econ. 88(1), 105–119 (2004)

Tempelmeier, H., Hilger, T.: Linear programming models for a stochastic dynamic capacitated lot sizing problem. Comput. Oper. Res. 59, 119–125 (2015)

Pishvaee, M.S., Torabi, S.A., Razmi, J.: Credibility-based fuzzy mathematical programming model for green logistics design under uncertainty. Comput. Ind. Eng. 62(2), 624–632 (2012)

Zadeh, L.A.: Fuzzy sets. Inf. Control. 8(3), 338–353 (1965)

Liu, B., Liu, Y.: Expected value of fuzzy variable and fuzzy expected value models. IEEE Trans. Fuzzy Syst. 10(4), 445–450 (2002)

Huang, X.: Credibility-based chance-constrained integer programming models for capital budgeting with fuzzy parameters. Inf. Sci. 176(18), 2698–2712 (2006)

Lan, Y., Liu, Y., Sun, G.: Modeling fuzzy multi-period production planning and sourcing problem with credibility service levels. J. Comput. Appl. Math. 231(1), 208–221 (2009)

Pourrahmani, E., Delavar, M.R., Mostafavi, M.A.: Optimization of an evacuation plan with uncertain demands using fuzzy credibility theory and genetic algorithm. Int. J. Disaster Risk Reduct. 14, 357–372 (2015)

Xu, Y., Qin, X.: Agricultural effluent control under uncertainty: An inexact double-sided fuzzy chance-constrained model. Adv. Water Resour. 33(9), 997–1014 (2010)

Öztürk, C., Örnek, A.M.: A MIP based heuristic for capacitated MRP systems. Comput. Ind. Eng. 63(4), 926–942 (2012)

Hu, Z., Hu, G.: A multi-stage stochastic programming for lot-sizing and scheduling under demand uncertainty. Comput. Ind. Eng. 119, 157–166 (2018)

Baykasoglu, A., Gocken, T.: Multi-objective aggregate production planning with fuzzy parameters. Adv. Eng. Softw. 41(9), 1124–1131 (2010)

Stadtler, H.: Mixed integer programming model formulations for dynamic multi-item multi-level capacitated lotsizing. Eur. J. Oper. Res. 94(3), 561–581 (1996)

Liu, B.: A survey of credibility theory. Fuzzy Optim. Decis. Mak. 5(4), 387–408 (2006)

Zadeh, L.A.: Fuzzy sets as a basis for a theory of possibility. Fuzzy Sets Syst. 1(1), 3–28 (1978)

Dubois, D., Prade, H.: Ranking fuzzy numbers in the setting of possibility theory. Inf. Sci. 30(3), 183–224 (1983)

Zhang, C., Guo, P.: A generalized fuzzy credibility-constrained linear fractional programming approach for optimal irrigation water allocation under uncertainty. J. Hydrol. 553, 735–749 (2017)

Sun, K., Qiu, J., Karimi, H.R., et al.: A novel finite-time control for nonstrict feedback saturated nonlinear systems with tracking error constraint. IEEE Trans. Syst. Man Cybern 2019, 1–12 (2019)

Acknowledgements

The authors are grateful to the intelligent manufacturing support project for major science and technology programs of Shaanxi Province (Grant No.2018zdzx01-01-01) and the financial support of the National Natural Science Foundation of China (Grant No. 51605041).

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix A: Proof of Theorem 1

Proof

(1): Because \(\alpha \le 1/2\) and \(Cr\left\{ {\hat{\xi } \le r} \right\} \ge \alpha\), from Eq. (17), it is easy to know that \(a_{1} \le r \le a_{2}\), and then we have \(\frac{{r - a_{1} }}{{2(a_{2} - a_{1} )}} \ge \alpha\), therefore conclusion(1) can be obtained.

(2) Similar to (1), if \(\alpha > 1/2\) and \(Cr\left\{ {\hat{\xi } \le r} \right\} \ge \alpha\), we have \(a_{2} \le r \le a_{3}\), according to Eq. (17), it is easy to prove the conclusion(2).

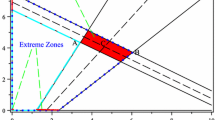

The graphical explanation of Theorem (2) is shown in Fig. 10.

Appendix B: Proof of Theorem 2

Proof

For a given fuzzy number \(\hat{\xi }\) = (\(a_{1} ,a_{2} ,a_{3}\)) is denoted by the membership function \(\mu\). It is easy to know that for any \(\lambda \in (0,1)\), there exist two values on the x-axis for the inverse function of \(\mu (x)\), they are \((1 - \lambda )a_{1} + \lambda a_{2}\) and \((1 - \lambda )a_{3} + \lambda a_{2}\), respectively, and \((1 - \lambda )a_{1} + \lambda a_{2}\) < \((1 - \lambda )a_{3} + \lambda a_{2}\), which can be viewed as two points of \( \user2{Ax} \) in real line R, as shown in Fig. 10. To ensure that \(Cr\left\{ {{\text{f}} (\user2{x}, {\varvec{\hat{\xi }}}) \le 0} \right\} \ge 1/2\), the smaller value, i.e.,\((1 - \lambda )a_{1} + \lambda a_{2}\) is valid according to Eq. (18).

Furthermore, since \(\user2{A,x} \in \user2{R}^{n}\), therefore \(\user2{Ax} \in \user2{R}\), and \(Cr\left\{ {{\text{f}} (\user2{x}, {\varvec{\hat{\xi }}}) \le 0} \right\} = Cr\left\{ {\user2{Ax} \le \hat{\xi }} \right\} \ge \alpha\). According to Theorem (2), we have \(2(1 - \alpha )a_{2} + (1 - 2\alpha )a_{1} - {\user2{Ax}} \ge 0\). As can be seen from the geometric relationship shown in Fig. 10, the following formula can be deduced:

Therefore, the proof of Theorem (3) is complete.

Appendix C:. Proof of Theorem 3.

Proof

Since both \(h_{k}^{ + } ({\mathbf{x}})\) and \(h_{k}^{ - } ({\mathbf{x}})\) are non-negative, and \(h_{k} ({\mathbf{x}}) = h_{k}^{ + } ({\mathbf{x}}) - h_{k}^{ - } ({\mathbf{x}})\), and we have

\(g({\mathbf{x}},\hat{\varvec{\xi }}, {\varvec{\hat{\eta }}}) = g({\mathbf{x}},\hat{\varvec{\xi }}) - \hat{\eta }\), \(Cr\left\{ {g({\mathbf{x}},\hat{\varvec{\xi }}, {\varvec{\hat{\eta }}}) \le 0} \right\}{ = }Cr\left\{ {g({\mathbf{x}},\hat{\varvec{\xi }}) \le \hat{\eta }} \right\}\).

According to Theorem (1), \(g({\mathbf{x}},\hat{\varvec{\xi }})\) is also a triangular fuzzy variable, and can be denoted as the following form:

And also, \(\hat{\eta }{ = (}b_{1} {,}b_{2} ,b_{3} {)}\), according to Eq. (22), it is easy to prove that Eqs. (29) and (30) are true.

Rights and permissions

About this article

Cite this article

Zhu, B., Li, Y. & Zhang, F. A Credibility-Based MPS/MRP Integrated Programming Model Under Complex Uncertainty. Int. J. Fuzzy Syst. 23, 1414–1430 (2021). https://doi.org/10.1007/s40815-020-01041-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40815-020-01041-2