Abstract

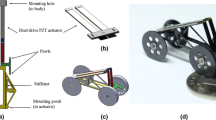

Millimeter-scale micro-robotic leg actuators are described that integrate thin-film lead zirconate titanate (PZT) piezoelectric actuation with compliant structures formed from parylene-C polymer. Models for out-of-plane rotation using piezoelectric cantilevers and in-plane rotation using high-aspect ratio polymer beams are discussed. Opportunities are highlighted for thin polymer films to aid in load-bearing, flexibility, and resilience of piezoelectric micro-robot appendages. A simple 5 mm × 2.4 mm × 0.15 mm hexapod robot prototype incorporating multiple actuators in each leg assembly is fabricated and tested within the silicon wafer in which it was built. Completed robot leg performance shows close agreement between modeled and tested static and dynamic characteristics, with potential benefits for future walking micro-robots from low power requirements relative to payload capacity and large amplitude motion at resonance.

Similar content being viewed by others

References

Aktakka, E.E., Woo, J.K., Egert, D., Gordenker, R., Najafi, K.: A Vibratory Stage for on Chip Physical Stimulation and Calibration of MEMS Gyroscopes. IEEE ISISS, Laguna Beach (2014)

Ash, B.J., Stone, J., Roger, D.F., Schadler, L.S., Siegel, R.W., Benicewicz, B.C., Apple, T.: Investigations into the Thermal and Mechanical Behavior of PMMA/Alumina Nanocomposites. Proc. MRS, Boston (2001)

Baisch, A., Wood, R.: Design and fabrication of the Harvard ambulatory micro-robot. Robot. Res. 70, 715–730 (2011)

Baumeister, G., Mueller, K., Ruprecht, R., Hausselt, J.: Production of metallic high aspect ratio microstructures by microcasting. Microsyst. Technol. 8(2), 105–108 (2002)

Becker, H., Heim, U.: Hot embossing as a method for fabrication of polymer high aspect ratio structures. Sens. Actuators 83, 130–135 (2000)

Bergbreiter, S., Pister, K.: Design of an Autonomous Jumping Microrobot. IEEE ICRA, Rome (2007)

Birkmeyer, P., Petersen, K., Fearing, R.S.: DASH: A Dynamic 16 g Hexapedal Robot. IEEE/RSJ ICRS, St. Louis (2009)

Cymbet Corp.: Enerchip rechargeable solid state bare die batteries. http://www.cymbet.com (2016)

Conway, N.J., Traina, Z.J., Kim, S.-G.: A strain amplifying piezoelectric MEMS actuator. J. Micromech. Microeng. 17, 781–787 (2007)

Dellmann, L., Roth, S., Beuret, C., Racine, G., Lorenz, H., Despont, M., Renaud, P., Vettiger, P., de Rooij, N.: Fabrication Process Of High-Aspect Ratio Elastic Structures For Piezoelectric Motor Applications. Transducers, Chicago (1997)

Ebefors, T., Mattsson, Kalvesten, J.E., Stemme, G.: A walking silicon micro-robot. Proceedings of the 10th International Conference on Solid-State Sensors Actuators, pp. 1202–1205, Sendai (1999)

Edamana, B., Oldham, K.R.: A near-optimal sensor scheduling strategy for an on-off controller with an expensive sensor. IEEE/ASME T Mech. 19(1), 158–170 (2014)

Edamana, B., Hahn, B., Pulskamp, J.S., Polcawich, R.G., Oldham, K.: Modeling and optimal low-power on-off control of thin-film piezoelectric rotational actuators. IEEE/ASME Trans. Mech. 16(5), 884–896 (2011)

Erdem, E.Y., Chen, Y.-M., Mohebbi, M., Suh, J.W., Kovacs, G.T.A., Darling, R.B., Bohringer, K.F.: Thermally-actuated omnidirectional walking microrobot. J MEMS 19(3), 433–442 (2010)

Espinosa, H.D., Prorok, B.C.: Size effects on the mechanical behavior of gold thin films. J. Mat. Sci. 38, 4125–4128 (2003)

Evans, J.: PZT-silicon cantilever benders. http://www.ferrodevices.com (2001)

Fu, Y., Harvey, E., Ghantasala, M., Spinks, G.: Design, fabrication, and testing of piezoelectric polymer PVDF microactuators. Smart Mat. Struct. 15(1), S141 (2005)

General Electronics Battery Co., Ltd.: Produce specification (for high discharge ratio battery). http://www.powerstream.com (2011)

Guerre, R., Drechsler, U., Bhattacharyya, D., Rantakati, P., Stutz, R., Heikkila, T., Kirby, P.B., Despont, D.: Wafer-level transfer technologies for PZT-Based RF MEMS Switches. J. MEMS 19(3), 548–560 (2010)

Hariri, H., Prasetya, L.A., Foong, S., Soh, G.S., Otto, K.N., Wood, K.L.: A tether-less legged piezoelectric miniature robot using bounding gait locomotion for bidirectional motion. IEEE ICRA, Stockholm (2016a)

Hariri, H., Prasetya, L.A., Soh, G.S., Wood, K.L.: Tether-less legged piezoelectric miniature robot using bounding gait locomotion for bidirectional motion. IEEE ICRA, Stockholm (2016b)

Hollar, S., Flynn, A., Bellew, C., Pister, K.: Solar Powered 10 mg Silicon Robot. IEEE C, MEMS (2003)

Hollar, S., Flynn, A., Bergbreiter, S., Pister, K.S.J.: Robot leg motioon in a planarized-SOI, two-layer poly-Si process. J MEMS 14(4), 725–740 (2005)

Kim, B., Ryu, J., Jeong, Y., Tak, Y., Kim, B., Park, J.-O.: A ciliary Based 8-Legged Walking Micro Robot Using Cast IPMC Actuators. IEEE ICRA, Taipei (2003)

Kladitis, P.E., Bright, V.M.: Prototype microrobots for micro-positioning and micro-unmanned vehicles. Sensors Actuators 80, 132–137 (2000)

Lam, T., Lam, K., Chan, H.: Micromachined piezoelectric polymer membrane acoustic sensor. Integr. Ferroelec. 76(1), 31–37 (2005)

Liu, G., Tian, Y., Kan, Y.: Fabrication of high-aspect-ratio microstructures using SU8 photoresist. Microsyst. Technol. 11, 343–346 (2005)

Lu, B.: Parylene as a new membrane material for biomems applications. California Institute of Technology, Pasadena (2012)

Luo, Y., Lu, M., Cui, T.: A polymer-based bidirectional micropump driven by a PZT bimorph. Microsyst. Tech. 17, 403–409 (2011)

Ma, K., Chirarattananon, P., Fuller, S.W.R.: Controlled flight of a biologically inspired, insect-scale robot. Science 340(6132), 603–607 (2013)

Mohebbi, M.H., Terry, M.L., Bohringer, K.F., Kovacs, G.T.A., Suh, J.W.: Omindirectional Walking Microrobot Realized By Thermal Microactuator Arrays. ASME IMECE, New York (2001)

Murthy, R., Stephanou, H.E., Popa, D.: AFAM: an articulated four axes micro-robot for nanoscale applications. IEEE Trans. Automat. Sci. Eng. 10(2), 276–284 (2012)

Navarre, A., Rocks, S., Dewey, R.: Micromoulding of lead zirconate titanate (PZT) structures for MEMS. J. Electroceram. 19, 321–326 (2007)

Nemirovsky, Y., Nemirovsky, A., Muralt, P., Setter, N.: Design of a novel thin-film piezoelectric accelerometer. Sensors Actuators A 50, 239–249 (1996)

Oldham, K., Pulskamp, J.S., Polcawich, R.G., Dubey, M.: Thin-film piezoelectric lateral actuators with extended stroke. J. MEMS 17(4), 890–899 (2008)

Oldham, K., Edamana, B., Hahn, B.: Coordinated voltage conversion and low-power micro-actuator switching. ASME DSCC, Arlington (2011)

Owen, K.J., VanDerElzen, B., Peterson, R.L., Najafi, K.: High Aspect Ratio Deep Silicon Etching. IEEE C. MEMS, Paris (2012)

Park, J., Lee, S., Cho, J., Jung, S., Han, J., Kang, S.: Acoustic and electromechanical properties of 1-3 PZT composites for ultrasonic transducer arrays fabricated by sacrificial micro PMMA mold. Sensors Actuators A 108, 206–211 (2003)

Pelc, E.H., Daley, M.A., Ferris, D.P.: Resonant hopping of a robot controlled by an artificial neural oscillator. Bioinspiration Biomim. 3(2), 026001 (2008)

Pulskamp, J.: Millimeter-scale MEMS Enabled Autonomous Systems: System Feasibility and Mobility. SPIE, Baltimore (2012)

Qu, J., Oldham, K.: Multiple Mode Dynamic Model for Piezoelectric Micro-Robot Walking. ASME IDETC, Charlotte (2016)

Rasmussen, J., Bonivert, W., Krafcik, J. High Aspect Ratio Metal MEMS (LIGA) Technologies For Rugged, Low-Cost Firetrain And Control Components, NDIA 47th Fuze Conference (2003)

Rhee, C.H., Pulskamp, J.S., Polcawich, R.G., Oldham, K.R.: Multi-degree-of-freedom thin-film PZT-actuated microrobotic leg. J. MEMS 21(6), 1492–1503 (2012)

Rios, S.A., Fleming, A.J., Yong, Y.K.: Design and Characterization of a Miniature Monolithic Piezoelectric Hexapod Robot. IEEE AIM, Banff (2016)

Rios, S.A., Fleming, A.J., Yong, Y.K.: Miniature resonant ambulatory robot. IEEE Robot. Autom. Lett. 2, 337–343 (2017)

Ritter, T., Geng, X., Shung, K.K., Lopath, P.D., Park, S.-E., Shrout, T.R.: Single crystal PZN/PT-polymer composites for ultrasound transducer applications. IEEE Trans. Ultrasonics 47(4), 792–800 (2002)

Robin, C., Vishnoi, A.: Mechanical behavior and anisotropy of spin-coated SU-8 thin-film for MEMS. J. MEMS 23(1), 168–180 (2013)

Sanuy, A., Casanova, R., Dieguez, A., Samitier, J., Szymanski, M., Worn, H.: Energy Efficient HW/SW Integration in an Autonomous Microrobot: 12th World Multi-C. Systemics Cybernetics Informatics, Orlando (2008)

Selvarasah, S., Chao, S.H., Chen, C.-L., Mao, D., Hopwood, J., Ryley, S., Sridar, S., Khademhosseini, A., Busnaina, A., Dokmeci, M.R.: A high aspect ratio, flexible, transparent and low-post parylene-C shadow mask technology for micropattering applications. Solid State Sensors Actuators Microsyst. C, Lyon (2007)

Shareef, I.A., Rubloff, G.W., Anderle, M., Gill, W.N., Cotte, J., Kim, D.H.: Subatmospheric chemical vapor deposition ozone/TEOS process for SiO2 trench filling. J. Vac. Sci. Technol. 13(4), 1888–1895 (1995)

Sharpe Jr., W.N., Gianola, P.J.D.S., Eberl, C., Polcawich, R.G., Thompson, R.J.: Strain measurements of silicon dioxide microspecimens by digital image processing. Exp. Mech. 5(649–658), 47–50 (2006)

Shih, V.C.-Y., Harder, T.A., Tai, Y.C.: Yield Strength of Thin-Film Parylene-C, Symp. MEMS/MOEMS (DTIP), Cote D’Azur (2003)

Shin, M., Choi, J., Rudy, R.Q., Kao, C., Pulskamp, J.S., Polcawich, R.G., Oldham, K.R.: Micro-robotic Actuation Units Based On Thin-Film Piezeoelectric and High-Aspect Ratio Polymer Structures. ASME IDETC, Buffalo (2014)

Sugita, K., Daisuke, T., Ono, S., Chiba, S., Iwata, K., Han, Y., Takato, M., Uchikoba, F., Saito, K.: SMA Actuator and Pulse-Type Hardware Neural Networks IC for Fat Walking Motion Of Insect-Type MEMS Microrobot. IEEE AIM, Banff (2016)

Suzuki, Y., Tai, Y.: Micromachined high-aspect ratio parylene spring and its application to low-frequency accelerometers. J. MEMS 15(5), 1364–1370 (2006)

Timpano, K.: Mechanical Characterization of Gold Thin Films for RF MEMS. Proc. Virginia Space Grant Consortium Student Conf., Richmond (2005)

Venkatragavaraj, E., Satish, B., Vinod, P., Vijaya, M.: Piezoelectric properties of ferroelectric PZT-polymer composites. J. Phys. D Appl. Phys. 34(4), 487–494 (2000)

Vogtmann, D.E., Gupta, S.K., Bergbreiter, S.: Multi-Material Compliant Mechanisms for Mobile Millirobots. IEEE ICRA, Shanghai (2011)

Wang, Q.-W., Cross, L.E.: Constitutive equations of symmetrical tri-layer piezoelectric benders. IEEE Trans Ultrasonics, Ferroelec. Freq. Control 46(6), 1343–1352 (1999)

Wilson, C.J., Ormeggi, A., Narbutovskih, M.: Fracture testing of silicon micro-cantilever beams. J. Appl. Phys. 5, 142–150 (1996)

Acknowledgements

The authors thank the National Science Foundation, Grants CMMI 0954422, IIS 1208233 and CMMI 1435222, and the Army Research Laboratory Summer Research Opportunities Program for support of this research.

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

Combined behavior of multiple polymer elements from in-plane rotation mechanisms is modeled by series of force balance, compliance, and geometric constraint equations for the elements previously introduced in Fig. 5. These equations are applied in up to five dimensions, neglecting torsion of beams in the parallel direction of the actuators (about the x-axis as defined in Fig. 5). Force balances about the individual components can be summarized as

where F 0 is the input force from the piezoelectric beam and F 1, F 2, and F 3 are the force vectors at the right-hand side of the elements (tether, rigid link, and tether respectively), where T 1, T 2, and T 2 are matrices computing static force balances from forces on the left-hand side of the elements in their neutral position, i.e.

where L t is the tether length, w b is the width of the rigid link, and T 3 is identical to T 1 but using flexure dimensions.

Deformation of the elastic parylene elements is calculated as the difference between tip positions and their projected neutral location based on their initial rotation angles,

where u 1 and u 3 are tip displacements of the tether and flexure, respectively (with u 3 = 0 when anchored to the substrate). In (10), V f and V t are matrices projecting the neutral position of the tether and flexure tips given rotation of earlier links, and C f and C t are compliance matrices for the tether and flexure, respectively. Projection matrices are given by

with L f being the flexure length. The compliance matrix for the flexure in the tether-flexure assembly is calculated from simple Bernoulli bending theory with a simple shear stress adjustment in the y-direction,

where A f is the flexure’s cross-sectional area, I f is its area moment of inertia about z or y axes, and E p and G p are the elastic and shear moduli of parylene-C, respectively.

Geometric constraints for the rigid element are compiled in matrix form,

where S 2 is a matrix projecting displacement at u 2 from u 1 for small angular rotations,

Equations (8)–(14) can be solved by linear algebra to either relate a specified input force to a multi-axis displacements of the flexure and tether endpoints and rigid link, or more generally to calculate the combined stiffness matrix, K, used to calculate actuator displacement numerically when accounting for nonlinear arc lengths effects introduced in (5)–(7) in Sect. 2.3.

Rights and permissions

About this article

Cite this article

Choi, J., Shin, M., Rudy, R.Q. et al. Thin-film piezoelectric and high-aspect ratio polymer leg mechanisms for millimeter-scale robotics. Int J Intell Robot Appl 1, 180–194 (2017). https://doi.org/10.1007/s41315-017-0017-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41315-017-0017-7