Abstract

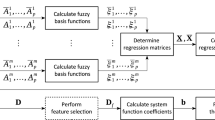

This paper describes a new diagnosis system, which is based on fuzzy reasoning to monitor the performance of a discrete manufacturing process and to justify the possible causes. The diagnosis system consists chiefly of a knowledge bank and a reasoning mechanism. The knowledge bank provides knowledge of the membership functions of unnatural symptoms that are described by Nelson's rules on X control charts and knowledge of cause-symptom relations. We develop an approach called maximal similarity method (MSM) for knowledge acquisition to construct the fuzzy cause-symptom relation matrix. Through the knowledge bank, the diagnosis system can first determine the degrees of an observation fitting each unnatural symptom. Then, using the fuzzy cause-symptom relation matrix, we can diagnose the causes of process instability. In conclusion we provide a numerical example to illustrate the system.

Similar content being viewed by others

References

Al-Ghanim, A. M. and Kamat, S. J. (1995) Unnatural pattern recognition on control charts using correlation analysis techniques. Computers and Industrial Engineering, 29(1-4), 43-47.

Beliakov, G. (1996) Fuzzy sets and membership functions based on probabilities. Information Science, 91, 95-111.

Davis, L. (1991) Handbook of Genetic Algorithms, Ed. Van Nostrand Reinhold, New York.

Goldberg, D. E. (1989) Genetic Algorithms in Search, Optimization, and Machine Learning, Addison-Wesley, Reading, MA.

Guo, Y. and Dooley, K. J. (1992) Identification of change structure in statistical process control. International Journal of Production Research, 30(7), 1655-1669.

Gwee, B. H., Lim, M. H. and Soong, B. H. (1996) Self-adjusting diagnostic system for the manufacture of crystal resonators. IEEE Transactions on Industry Application, 32(1), 73-79.

Hwarng, H. B. and Hubele, N. F. (1991) X-bar chart pattern recognition using neural nets. Annual Quality Congress Transactions, 45, 884-889.

Hwarng, H. B. and Hubele, N. F. (1993) Back-propagation pattern recognition for \(\overline X \) control charts: methodology and performance. Computers and Industrial Engineering,24(2), 219-235.

Karr, C. L. and Gentry, E. J. (1993) Fuzzy control of pH using genetic algorithms. IEEE Transactions on Fuzzy Systems, 1(1), 46-53.

Nelson, L. S. (1984) The Shewhart control chartÐtest for special causes. Journal of Quality Technology, 16, 237-239.

Nelson, L. S. (1985) Interpreting Shewhart _ X control charts. Journal of Quality Technology, 17(2), 114-116.

Pedryrcz, W. (1983) Numerical and applicational aspects of fuzzy relational equations. Fuzzy Sets and Systems, 11, 1-18.

Wang, H. F. (1993) Numerical analysis on fuzzy relation equations with various operators. Fuzzy Sets and Systems, 53, 155-166.

Western Electric Co. (1985) Statistical Quality Control Handbook, Western Electric Co. Inc, Indianapolis, Indiana.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Hsu, HM., Chen, YK. A fuzzy reasoning based diagnosis system for X control charts. Journal of Intelligent Manufacturing 12, 57–64 (2001). https://doi.org/10.1023/A:1008903614042

Issue Date:

DOI: https://doi.org/10.1023/A:1008903614042