Abstract

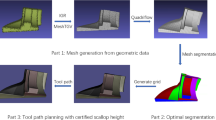

The manufacturing of complex bent parts can be supported effectively by computer-aided planning methods. Software systems are already available for unfolding, laser cutting and bending sequence determination. The paper focuses on methods that support the design of non-standard bending tools and the flexible manufacturing of such tools using laminated object modelling (LOM) technology. The developed system allows for concurrent planning and manufacturing of bending parts and tools. Within the framework of this system, neural networks are applied for automated tool design.

Similar content being viewed by others

References

de Vin, L. J., de Vries, J., Streppel, A. H. and Kals, H. J. J. (1992) PARTS-S, a CAPP system for small batch manufacturing of sheet metal components, in 24th CIRP International Seminar on Manufacturing Systems, Copenhagen.

Franke, V. (1995) Automation of tool planning for bent components, in Proceedings of the SheMet '95, Birmingham, pp. 35–44.

Geiger, M. and Backes, F. (1995) Wissensbasiertes System zur Biegestadienplanung, in Flexible Umformtechnik — Abschluβkolloquium zum DFG-Schwerpunktprogramm. RWTH Aachen, pp. 6.1–6.1.11.

Geiger, M. and Kolléra, H. (1994) Tool path optimization for 2D laser cutting. Production Engineering, 2, 155–158.

Geiger, M. and Vormann, B. (1994) Planungssystem für das Handhaben komplexer Blechbiegeteile. Bänder, Bleche, Rohre, 3, 28–32.

Hoffmann, M. (1992) Entwicklung einer CAD/ CAM-Prozeßkette für die Herstellung von Blechbiegeteilen, in Fertigungstechnologie Erlangen, No. 28, K. Feldmann and M. Geiger (eds), Carl Hanser Verlag, Munich.

Kolléra, H. (1993) Entwicklung eines benutzer-orientierten Werkstattprogrammiersystems für das Laserstrahlschneiden, in Fertigungstechnologie Erlangen, No. 36, K. Feldmann and M. Geiger (eds), Carl Hanser Verlag, Munich.

Kuzman, K., Pepelnjak, T. and Hoffmann, P. (1994) Flexible Herstellung von Lamellenwerkzeugen mittels Laserstrahlschneiden. Blech, Rohre, Profile, 4, 241–245.

Nakagawa, T. (1987) New manufacturing processes of metal forming tools, in Proceedings of the second ICTP, Vol. 1, Advanced Technology of Plasticity, TU Stuttgart, pp. 83–89.

Riedmiller, M. and Braun, H. (1993) A direct adaptive method for faster backpropagation learning: the RPROP algorithm, in Proceeding of the IEEE International Conference on Neural Networks, San Francisco.

Schreiber, M. P. and Clyens, S. (1993) Blanking tools manufactured by laminating laser cut steel sheets, in Proceedings of the fourth NOLAMP Conference Sonderborg, Denmark, pp. 31–37.

Shpitalni, M. and Saddan, D. (1994) Automatic determination of bending sequence in sheet metal products. Annals of CIRP, 1, 23–26.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Backes, F., Franke, V. & Geiger, M. Concurrent manufacturing of parts and tools for the sheet-metal industry. Journal of Intelligent Manufacturing 9, 347–352 (1998). https://doi.org/10.1023/A:1008930926776

Issue Date:

DOI: https://doi.org/10.1023/A:1008930926776