Abstract

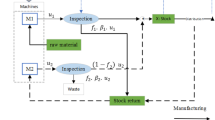

The objective of this article is to present an expository overview of our recent studies on developing dynamic approaches to quality control in batch manufacturing. The approaches are dynamic in the sense that they are concerned with finding policies or controls, instead of merely parametric or statistical designs. In particular, we emphasize identifying certain optimal sequential procedures and revealing their structural properties. We shall review our studies on the following issues:(i)coordination between the inspection‐repair of finished products and their follow‐upservices; (ii) coordination between inspection of different component parts in assembly lines;(iii) coordination between inspection and process revision; and(iv) inter‐stage coordination

-of the inspection processes at different stages

-under capacity constraints, and

-between production and inspection.

The basic methodology underlying our approaches is Markov decision programming (MDP). We also incorporate into MDP the usage of stochastic comparison techniques, including those based on notions of stochastic convexity and stochastic submodularity. These properties play a crucial role in revealing the structures of the policies and in proving their optimality.

Similar content being viewed by others

References

S.L. Albin and D.J. Friedman, The impact of clustered defect distributions in IC fabrication, Management Science 35(1989)1066-1078.

D. Ballou and H. Pazer, The impact of inspector facility on the inspection policy in serial production systems, Management Science 28(1982)387-399.

J. Banks, Principles of Quality Control, Wiley, New York, 1989.

F.J. Beutler and K.W. Ross, Optimal policies for controlled Markov chains with a constraint, J. of Math. Anal and Appl. 112(1985)236-252.

W.R. Blischke, Mathematical models for analysis of warranty policies, Math. Comput. Modeling 13(1990)1-16.

J.A. Buzacott and J.G. Shanthikumar, Design of manufacturing systems using queueing models, Queueing Systems 12(1992)135-214.

J.A. Buzacott and J.G. Shanthikumar, Stochastic Models of Manufacturing Systems, Prentice-Hall, Englewood Cliffs, NJ, 1993.

J.A. Buzacott and D.D. Yao, On queueing network models of flexible manufacturing systems, Queueing Systems 1(1986)5-28.

C.S. Chang, J.G. Shanthikumar and D.D. Yao, Stochastic convexity and stochastic majorization, in: Stochastic Modeling and Analysis of Manufacturing Systems, ed. D.D. Yao, Springer, New York, 1994, chapter 5.

K. Chittayil, R.T. Kumara and P.H. Cohen, Acoustic emission sensing for tool wear monitoring and process control in metal cutting, in: Handbook of Design, Manufacturing and Automation, eds. R.C. Dorf and A. Kusiak, Wiley, New York, 1994, chapter 33.

H. Chen, M.J. Harrison, A.V. Ackere and L.M. Wein, Empirical evaluation of a queueing network model for semiconductor wafer fabrication, Operations Research 36(1988)202-215.

H. Chen, P. Yang and D.D. Yao, Control and scheduling in a two-station network: Optimal policies and heuristics, Queueing Systems 18(1994)301-332.

J. Chen, D.D. Yao and S. Zheng, Quality control for finished products under warranty, Operations Research 46(1998)107-115.

J. Chen, D.D. Yao and S. Zheng, Coordinated quality control in an assembly line, Preprint.

D.W. Cheng and D.D. Yao, Tandem queues with general blocking: A unified model and stochastic comparisons, Discrete Event Dynamic Systems 2(1993)207-234.

Y.S. Chow, H. Robbins and D. Siegmund, Great Expectations, The Theory of Optimal Stopping, Houghton Mifflin, New York, 1972.

D.E. Coleman, Generalized control charting, in: Statistical Process Control in Automated Manufacturing, eds. J.B. Keats and N.F. Hubele, Marcel Dekker, New York, 1989.

D. Connors, G. Feigin and D.D. Yao, Scheduling semiconductor lines using a fluid network model, IEEE Transactions on Robotics and Automation 10(1994) 88-98.

D. Connors, G. Feigin and D.D. Yao, A queueing network model for semiconductor manufacturing, IEEE Transactions on Semiconductor Manufacturing 9(1996)412-427.

S.V. Crowder, An application of adaptive Kalman filtering to statistical process control, in: Statistical Process Control in Automated Manufacturing, eds. J.B. Keats and N.F. Hubele, Marcel Dekker, New York, 1989.

L. Dan and J. Mathew, Tool wear and failure monitoring techniques for turning — a review, Int. J. Mach. Tool Manufacturing 30(1990)579-598.

W.E. Deming, Foreword to Statistical Method from the Viewpoint of Quality Control, ed. W.A. Shewhart, Dover, New York, 1986.

W.E. Deming, Out of the Crisis, MIT Press, Cambridge, MA, 1986.

C. Derman, Finite State Markovian Decision Processes, Academic Press, New York, 1970.

G.D. Eppen and E.G. Hurst, Optimal location of inspection stations in a multistage production process, Management Science 20(1974)1194-1200.

E.A. Feinberg, Constrained semi-Markov decision processes with average rewards, ZOR — Mathematical Methods of Operations Research 39(1994)257-288.

G. Gallego, D.D. Yao and I. Moon, Optimal control of a production process with trial runs, Management Science 39(1993)1499-1505.

M.A. Girshick and H. Rubin, A Bayes approach to a quality control model, Ann. of Math. Statist. 23(1952)114-125.

P. Glasserman and D.D. Yao, Monotone Structure in Discrete-Event Systems, Wiley, New York, 1994.

P. Glasserman and D.D. Yao, A GSMP framework for the analysis of production lines, in: Stochastic Modeling and Analysis of Manufacturing Systems, ed. D.D. Yao, Springer, New York, 1994, chapter 4.

P. Glasserman and D.D. Yao, Monotone optimal control of permutable GSMPs, Mathematics of Operations Research 19(1994)449-476.

P. Glasserman and D.D. Yao, Structured buffer allocation problems, Discrete Event Dynamic Systems 6(1996)9-29.

N.F. Hubele, A multivariate and stochastic framework for statistical process control, in: Statistical Process Control in Automated Manufacturing, eds. J.B. Keats and N.F. Hubele, Marcel Dekker, New York, 1989.

L. Kallenberg, Linear Programming and Finite Markovian Control Problems, Math. Centre Tracts 148, Mathematisch Centrum, Amsterdam, 1983.

P.R. Kumar, Re-entrant lines, Queueing Systems 13(1993)87-110.

H. Lee, A multi-echelon inventory model for repairable items with emergency lateral transhipments, Management Science 33(1987)1302-1316.

C.H. Lie and Y.H. Chun, Optimum single-sample inspection plans for products sold under free and rebate warranty, IEEE Trans. on Reliability R-36(1987) 634-647.

G.F. Lindsay and A. Bishop, Allocation of screening inspection effort: A dynamic programming approach, Management Science 10(1964)342-352.

M.D. Longtin, L.M. Wein and R.E. Welsch, Sequential screening in semiconductor manufacturing, II: Exploiting spatial dependence, Operations Research 44(1996)173-195.

T.J. Lorenzen, Minimum cost sampling plans using Bayesian methods, Naval Res. Logistics 32(1985)57-69.

E. Menipaz, A taxonomy of economically based quality control problems, International Journal of Production Research 16(1978)153-167.

A. Mitra, Fundamentals of Quality Control and Improvement, Macmillan, New York, 1993.

D. Montgomery, Introduction to Statistical Quality Control, Wiley, New York, 1991.

D.G. Nguyen and D.N.P. Murthy, An optimal policy for servicing warranty, J. Oper. Res. Soc. 37(1986)1081-88.

J. Ou and L.M. Wein, Sequential screening in semiconductor manufacturing, I: Exploiting lot-to-lot variability, Operations Research 44(1996)196-205.

M.S. Phadke, Quality evaluation plan using adaptive Kalman filtering, Bell Syst. Tech. J. 61(1981)2081-2107.

T. Raz, A survey of models for allocating inspection effort in multistage production systems, J. Quality Technology 18(1986)239-247.

S.M. Ross, Quality control under Markovian deterioration, Management Science 17(1971)587-596.

S.M. Ross, Stochastic Processes, 2nd ed., Wiley, New Yor, 1996.

S.M. Ross, Introduction to Stochastic Dynamic Programming, Academic Press, 1983.

H. Scarf, The optimality of (S, s) policies in the dynamic inventory problem, in: Mathematical Methods in the Social Sciences, eds. K.J. Arrow, S. Karlin and P. Suppes, Stanford University Press, Stanford, CA, 1960, pp. 196-202.

N. Schmitz, Optimal Sequentially Planned Decision Procedures, Springer, 1992.

M. Shaked and J.G. Shanthikumar, Stochastic convexity and its applications, Advances in Applied Probability 20(1988)427-446.

J.G. Shanthikumar and D.D. Yao, Strong stochastic convexity: Closure properties and applications, Journal of Applied Probability 28(1991)131-145.

J.G. Shanthikumar and D.D. Yao, Bivariate characterization of some stochastic order relations, Advances in Applied Probability 23(1991)642-659.

W.A. Shewhart, Statistical Method from the Viewpoint of Quality Control, Dover, New York, 1986.

N.D. Singpurwalla and S. Wilson, The warranty problem: Its statistical and game theoretic aspects, SIAM Review 35(1993)17-42.

G. Taguchi, A. Elsayed and T. Hsiang, Quality Engineering in Production Systems, McGraw-Hill, New York, 1989.

G. Taguchi and Y. Wu, Introduction to Off-Line Quality Control, Central Japan Quality Control Association, Nagoya, Japan, 1979.

S. Takata, M. Ogawa, P. Bertok, J. Ootsuka, K. Matushima and T. Sata, Real-time monitoring system of tool breakage using Kalman filtering, Robotics and Computer Integrated Manufacturing 2(1985)33-40.

C.S. Tapiero and H.L. Lee, Quality control and product servicing: A decision framework, Eur. J. Oper. Res. 39(1989)261-273.

C.S. Tang, Designing an optimal production system with inspection, Eur. J. Oper. Res. 52(1991)45-54.

K. Tang and J.M. Pruett, Manufacturing process quality control and improvement, in: Handbook of Design, Manufacturing and Automation, eds. R.C. Dorf and A. Kusiak, Wiley, New York, 1994, chapter 31.

H. Taylor, Markov sequential replacement processes, Ann. of Math. Statist. 36(1965)1677-1694.

M.U. Thomas, Optimum warranty policies for nonrepairable items, IEEE Trans. on Reliability R-32(1983)282-288.

J.R. Thompson and J. Koronacki, Statistical Process Control for Quality Improvement, Chapman and Hall, New York, 1993.

J. Tlusty and G.C. Andrews, A critical review of sensors for unmanned machining, Ann. CIRP (Annals of the Int. Inst. for Prod. Eng. Res.) 32(1983)563-572.

D.M. Topkis, Minimizing a submodular function on a lattice, Operations Research 26(1978)305-321.

L. White, The analysis of a simple class of multistage inspection plans, Management Science 9(1966)685-693.

L. White, Shortest route models for allocation of inspection effort on a production line, Management Science 15(1969)249-259.

A. Wald, Sequential Analysis, Dover, 1973.

D.D. Yao and S. Zheng, Coordinated production and inspection in a tandem system, Queueing Systems 24(1996)59-82.

D.D. Yao and S. Zheng, Coordinated quality control in a two-stage system, Preprint.

D.D. Yao and S. Zheng, Sequential quality control of a machining process, Proceedings of the 34th IEEE Conference on Decision and Control, New Orleans, LA, 1995.

D.D. Yao and S. Zheng, Sequential inspection under capacity constraints, Operations Research, to appear.

Rights and permissions

About this article

Cite this article

Yao, D., Zheng, S. Sequential quality control in batch manufacturing. Annals of Operations Research 87, 3–30 (1999). https://doi.org/10.1023/A:1018989120793

Issue Date:

DOI: https://doi.org/10.1023/A:1018989120793