Abstract

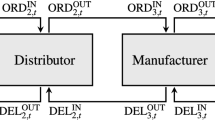

We consider the dynamic scheduling of a two-part-type make-to-stock production system using the model of Wein [12]. Exogenous demand for each part type is met from finished goods inventory; unmet demand is backordered. The control policy determines which part type, if any, to produce at each moment; complete flexibility is assumed. The objective is to minimize average holding and backorder costs. For exponentially distributed interarrival and production times, necessary and sufficient conditions are found for a zero-inventory policy to be optimal. This result indicates the economic and production conditions under which a simple make-to-order control is optimal. Weaker results are given for the case of general production times.

Similar content being viewed by others

References

T. Bielecki and P.R. Kumar, Optimality of zero-inventory policies for unreliable manufacturing systems, Oper. Res. 36 (1988) 532–546.

F. de Véricourt, F. Karaesmen and Y. Dallery, Dynamic scheduling in a make-to-stock system: A partial characterization of optimal policies, Oper. Res. 48 (2000) 811–819.

D. Gross and C.M. Harris, Fundamentals of Queueing Theory (Wiley, New York, 1985).

A. Ha, Optimal dynamic scheduling policy for a make-to-stock production system, Oper. Res. 45 (1997) 42–53.

J. Keilson and L.D. Servi, The distributional form of Little's law and the Furhmann–Cooper decomposition, Oper. Res. Lett. 9 (1990) 239–247.

A. P?na-Perez and P. Zipkin, Dynamic scheduling rules for a multi-product make-to-stock queue, Oper. Res. 45 (1997) 919–930.

J.R. Perkins and R. Srikant, Hedging policies for failure-prone manufacturing systems: Optimality of JIT policies and bounds on buffer levels, IEEE Trans. Automat. Control (1998) 953–958.

E. Presman, S.P. Sethi, H. Zhang and Q. Zhang, Optimality of zero-inventory policies for an unreliable manufacturing system producing two part types, Dyn. Cont. Discrete Impulsive Systems 4 (1998) 485–496.

M.H. Veatch and M.C. Caramanis, Optimal manufacturing flow controllers: Zero-inventory policies and control switching sets, IEEE Trans. Automat. Control 44 (1999) 914–921.

M.H. Veatch and L.M. Wein, Scheduling a make-to-stock queue: Index policies and hedging points, Oper. Res. 44 (1996) 634–647.

R.R. Weber and S. Stidham, Optimal control of service rates in networks of queues, Adv. in Appl. Probab. 19 (1987) 202–218.

L.M. Wein, Dynamic scheduling of a multi-class make-to-stock queue, Oper. Res. 40 (1992) 724–735.

M.J. Yee and M.H. Veatch, Just-in-time policies for manufacturing flow controllers, IEEE Trans. Automat. Control 45 (2000) 336–339.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Veatch, M.H., De Véricourt, F. Zero-Inventory Conditions for a Two-Part-Type Make-to-Stock Production System. Queueing Systems 43, 251–266 (2003). https://doi.org/10.1023/A:1022846711722

Issue Date:

DOI: https://doi.org/10.1023/A:1022846711722