Paper:

Variable-Stiffness and Deformable Link Using Shape-Memory Material and Jamming Transition Phenomenon

Kazuto Takashima*, Toshiki Imazawa*, and Hiroki Cho**

*Graduate School of Life Science and Systems Engineering, Kyushu Institute of Technology

2-4 Hibikino, Wakamatsu-ku, Kitakyushu, Fukuoka 808-0196, Japan

**Faculty of Environmental Engineering, University of Kitakyushu

1-1 Hibikino, Wakamatsu-ku, Kitakyushu, Fukuoka 808-0135, Japan

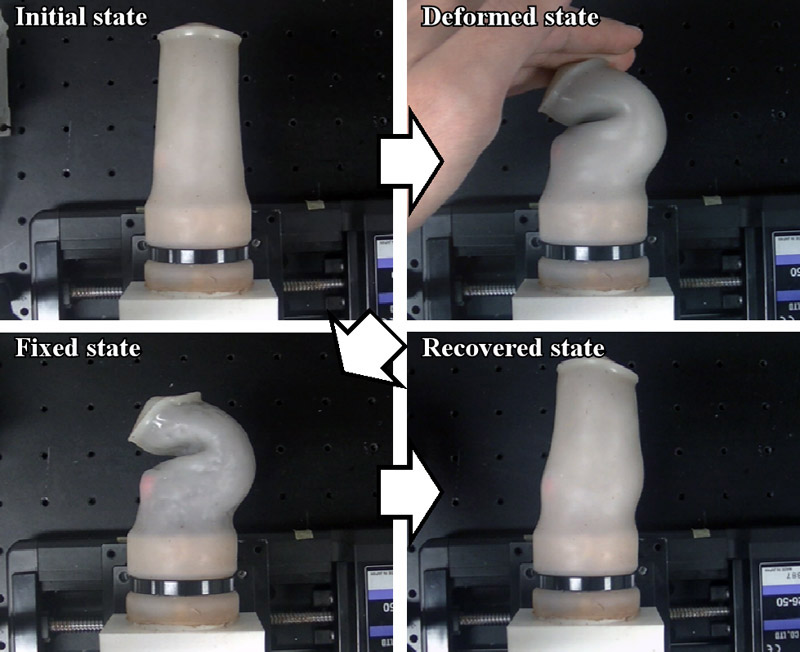

In this study, we developed a variable-stiffness and deformable link using shape-memory material and the jamming transition phenomenon. Above its glass transition temperature (Tg), a shape-memory polymer (SMP) can be deformed by applying a small load. SMPs maintain the deformed shape after they have been cooled below Tg, and they return to their original shape when heated above Tg. The reversible change in the elastic modulus between the glassy and rubbery states of SMPs can be on the order of 100–1000 times. We exploited the characteristics of SMPs to develop robot components with variable stiffness and sensitivity. The jamming transition phenomenon for granular material has been widely used as a method to change the stiffness of robots. This phenomenon is the change from fluid-like to solid-like conditions by removing air from a space containing particles. In this study, we developed a variable-stiffness link by combining the SMP and the jamming transition phenomenon. Moreover, by replacing the SMP with shape-memory alloys (SMAs), whose recovery force and elastic modulus are larger than those of SMPs, we prepared a second prototype with variable stiffness. We evaluated the performance of both prototypes, using the SMP or the SMA, with experiments and confirmed the motion principle of the proposed link (e.g., shape recovery and shape fixity). Moreover, it was confirmed that the stiffness of these links can be changed among four states.

Motion of prototype link

- [1] K. Takashima, D. Iwamoto, S. Oshiro, T. Noritsugu, and T. Mukai, “Characteristics of pneumatic artificial rubber muscle using two shape-memory polymer sheets,” J. Robot. Mechatron., Vol.33, No.3, pp. 653-664, doi: 10.20965/jrm.2021.p0653, 2021.

- [2] K. Takashima, K. Sugitani, N. Morimoto, S. Sakaguchi, T. Noritsugu, and T. Mukai, “Pneumatic artificial rubber muscle using shape-memory polymer sheet with embedded electrical heating wire,” Smart Mater. Struct., Vol.23, No.12, Article No.125005, doi: 10.1088/0964-1726/23/12/125005, 2014.

- [3] K. Takashima, J. Rossiter, and T. Mukai, “McKibben artificial muscle using shape-memory polymer,” Sensors & Actuators: A Physical, Vol.164, pp. 116-124, doi: 10.1016/j.sna.2010.09.010, 2010.

- [4] K. Takashima, T. Noritsugu, J. Rossiter, S. Guo, and T. Mukai, “Curved type pneumatic artificial rubber muscle using shape-memory polymer,” J. Robot. Mechatron., Vol.24, No.3, pp. 472-479, doi: 10.20965/jrm.2012.p0472, 2012.

- [5] K. Takashima, H. Kamizono, M. Takenaka, and T. Mukai, “Force sensor utilizing stiffness change of shape-memory polymer based on temperature,” Robomech J., Vol.4, Article No.17, doi: 10.1186/s40648-017-0086-2, 2017.

- [6] K. Takashima, R. Miyazaki, and T. Mukai, “Surface shape changeable tactile sensor using shape-memory polymer,” Proc. of the Annual Conf. of the Society of Instrument and Control Engineers of Japan (SICE) 2021, pp. 1166-1171, 2021.

- [7] Japan Institute of Invention and Innovation, “Patent Distribution Support Chart: Shape-Memory Polymers,” National Center for Industrial Property Information and Training, 2006 (in Japanese).

- [8] J. M. Jani, M. Leary, A. Subic, and M. A. Gibson, “A review of shape memory alloy research, applications and opportunities,” Mater. Des., Vol.56, pp. 1078-1113, doi:10.1016/j.matdes.2013.11.084, 2014.

- [9] H. Tobushi, K. Tanaka, H. Horikawa, and M. Matsumoto, “Shape Memory Materials and their Applications,” Corona Publishing, 2004 (in Japanese).

- [10] Y. Yang, Y. Chen, Y. Li, and M. Z. Chen, “3D printing of variable stiffness hyper-redundant robotic arm,” Proc. of IEEE Int. Conf. on Robotics and Automation (ICRA), Vol.2016-June, pp. 3871-3877, doi: 10.1109/ICRA.2016.7487575, 2016.

- [11] J. Shintake, V. Cacucciolo, D. Floreano, and H. Shea, “Soft robotic grippers,” Adv. Mater., Vol.30, Article No.1707035, doi: 10.1002/adma.201707035, 2018.

- [12] S. Yahara, S. Wakimoto, T. Kanda, and K. Matsushita, “McKibben artificial muscle realizing variable contraction characteristics using helical shape-memory polymer fibers,” Sensors and Actuators, A: Physical, Vol.295, pp. 637-642, doi: 10.1016/j.sna.2019.06.012, 2019.

- [13] Y. An and H. Okuzaki, “Novel electro-active shape memory polymers for soft actuators,” Jpn. J. Appl. Phys., Vol.59, Article No.061002, doi: 10.35848/1347-4065/ab8e08, 2020.

- [14] M. Fujita, T. Fujimoto, H. Tetsui, A. Nishumura, A. Nomura, E. Takane, H. Komatsu, K. Tadakuma, M. Konyo, and S. Tadokoro, “Tufted jamming membrane gripper mechanism – Quantitative evaluation experiment as pushing force –,” Proc. of 18th SICE System Integration Division Annual Conference (SI2017), pp. 1669-1673, 2017 (in Japanese).

- [15] E. Brown, N. Rodenberg, J. Amend, A. Mozeika, E. Steltz, M. R. Zakin, H. Lipson, and H. M. Jaeger, “Universal robotic gripper based on the jamming of granular material,” Proc. Natl. Acad. Sci. U.S.A., doi: 10.1073/pnas.1003250107, 2010.

- [16] T. Nishida, D. Shigehisa, N. Kawashima, and K. Tadakuma, “Development of universal jamming gripper with a force feedback mechanism,” Proc. of 7th Int. Conf. on Soft Computing and Intelligent Systems (SCIS) and 15th Int. Symp. on Advanced Intelligent Systems (ISIS), pp. 242-246, doi: 10.1109/SCIS-ISIS.2014.7044693, 2014.

- [17] K. Yokouchi, T. Kamegawa, T. Matsuno, T. Hiraki, T. Yamaguchi, and A. Gofuku, “Development of a gripper with variable stiffness for a CT-guided needle insertion robot,” J. Robot. Mechatron., Vol.32, No.3, pp. 692-700, doi: 10.20965/jrm.2020.p0692, 2020.

- [18] N. G. Cheng, M. B. Lobovsky, S. J. Keating, A. M. Setapen, K. I. Gero, A. E. Hosoi, and K. D. Iagnemma, “Design and analysis of a robust, low-cost, highly articulated manipulator enabled by jamming of granular media,” Proc. of IEEE Int. Conf. on Robotics and Automation (ICRA), pp. 4328-4333, doi: 10.1109/ICRA.2012.6225373, 2012.

- [19] A. Jiang, P. Dasgupta, K. Althoefer, and T. Nanayakkara, “Robotic granular jamming: A new variable stiffness mechanism,” J. of the Robotics Society of Japan, Vol.32, pp. 333-338, doi: 10.7210/jrsj.32.333, 2014.

- [20] S. Yamane and S. Wakimoto, “Development of a flexible manipulator with changing stiffness by granular jamming,” Proc. of 24th Int. Conf. on Mechatronics and Machine Vision in Practice (M2VIP), pp. 1-5, doi: 10.1109/M2VIP.2017.8211491, 2017.

- [21] E. Steltz, A. Mozeika, N. Rodenberg, E. Brown, and H. M. Jaeger, “JSEL: Jamming skin enabled locomotion,” Proc. of the 2009 IEEE/RSJ Int. Conf. on Intelligent Robots and Systems, pp. 5672-5677, doi: 10.1109/IROS.2009.5354790, 2009.

- [22] M. Yamano, N. Akiba, J. Gong, and H. Furukawa, “Experiments of a two-arm robot using shape memory gel,” Proc. of IEEE/SICE Int. Symp. on System Integration (SII), pp. 236-241, doi: 10.1109/SII.2012.6426947, 2012.

- [23] H. Nakai, Y. Hoshino, M. Inaba, and H. Inoue, “Softening deformable robot: Development of shape adaptive robot using phase change of low-melting-point alloy,” J. of the Robotics Society of Japan, Vol.20, pp. 625-630, doi: 10.7210/jrsj.20.625, 2002 (in Japanese).

- [24] S. Kise, “Material characteristics and application of shape memory alloys,” Plastos, Vol.1, pp. 132-137, doi: 10.32277/plastos.1.2_132, 2018 (in Japanese).

- [25] Y. Haga, Y. Tanahashi, and M. Esashi, “Small diameter active catheter using shape memory alloy,” Proc. of IEEE 11th Annual Int. Workshop on Micro Electro Mechanical Systems (MEMS), pp. 419-424, doi: 10.1109/MEMSYS.1998.659793, 1998.

- [26] H. Cho, T. Yamamoto, Y. Takeda, A. Suzuki, and T. Sakuma, “Exploitation of shape memory alloy actuator using resistance feedback control and its development,” Prog. Nat. Sci., Vol.20, pp. 97-103, doi: 10.1016/S1002-0071(12)60013-6, 2010.

- [27] H. Kino, N. Mori, S. Moribe, K. Tsuda, and K. Tahara, “Experiment verification and stability analysis of iterative learning control for shape memory alloy wire,” J. Robot. Mechatron., Vol.31, No.4, pp. 583-593, doi: 10.20965/jrm.2019.p0583, 2019.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.

This article is published under a Creative Commons Attribution-NoDerivatives 4.0 Internationa License.