Abstract

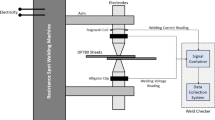

Resistance spot welding (RSW) is widely utilized as a joining technique for automobile industry. However, good weld quality control method has not yet been developed in plant environment when part fitup fault exists. This paper proposed a neuro-fuzzy algorithm to control weld quality by adjusting welding current. An experimental system was developed to measure electrode displacement curve. Accordingly based on electrode displacement curve optimal current for every cycle will be achieved under poor fitup fault condition. Results showed that proposed neuro-fuzzy system is suitable as a weld quality monitoring for resistance spot welding.

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

Nagel, G.L., Lee, A.: A new approach to spot welding feedback control, SAE Technical Paper, No. 880371 (1988)

Karagoulis, M.: Nuts-and-Bolts approach to the control of resistance spot welding. Welding Journal 73(7), 27–31 (1995)

Li, W., Cheng, S., Hu, S.J.: Statistical Investigation on Resistance Spot Welding Quality Using a Two-State, Sliding-Level Experiment. Journal of Manufacturing Science and Engineering-Transactions of The ASME 123(8), 513–520 (2001)

Cho, Y., Hu, S.J., Li, W.: Resistance spot welding of aluminum and steel: a comparative experimental study. Proceedings of the institution of mechanical engineers part B-Journal of Engineering Manufacture 217(7), 1355–1363 (2003)

Tsai, C.L., Dai, W.L., Dickinson, D.W., Papritan, J.C.: Analysis and development of a real-time control methodology in resistance spot welding. Welding Research Supplement 12, 339–351 (1991)

Cho, H.S., Chun, D.W.: A microprocessor-based electrode movement controller for spot weld quality assurance. IEEE Transactions on Industrial Electronics 32(3), 234–238 (1985)

Chang, H.S., Cho, Y.J., Choi, S.G., Cho, H.S.: A proportional-integral controller for resistance spot welding using nugget expansion. ASME Journal of Dynamic Systems, Measurement, and Control 111, 332–336 (1989)

Messler Jr., R.W., Jou, M.: An intelligent control system for resistance spot welding using a neural network and fuzzy logic. In: Conference Record-IAS Annual Meeting, pp. 1757–1763 (1995)

Jou, M.: Experimental investigation of resistance spot welding for sheet metals used in automotive industry. JSME International Journal Series C-Mechanical Systems Machine Elements and Manufacturing 44(2), 544–552 (2001)

Khoo, L.P., Young, H.Y.: A prototype fuzzy resistance spot welding system. International Journal of Production Research 33(7), 2023–2036 (1995)

Dilthey, U., Dickersbach, J.: Application of neural networks for quality evaluation for resistance spot welds. ISIJ International 39(10), 1061–1066 (1999)

Lee, S.R., Choo, Y.J.: A quality assurance technique for resistance spot welding using a neuro-fuzzy algorithm. Journal of manufacturing systems, 320–328 (2001)

Jang, S.R.: ANFIS: Adaptive-network-based fuzzy inference systems. IEEE Transactions on Systems, Man & Cybernetics 23(3), 665–685 (1993)

Kiguchi, K., Tanaka, T., Fukuda, T.: Neuro-fuzzy control of a robotic exoskeleton with EMG signals. IEEE Trans. Fuzzy Systems 12, 481–490 (2004)

Wang, L.P., Frayman, Y.: A Dynamically-generated fuzzy neural network and its application to torsional vibration control of tandem cold rolling mill spindles. Engineering Applications of Artificial Intelligence 15, 541–550 (2003)

Lin, C.-M., Hsu, C.-F.: Supervisory recurrent fuzzy neural network control of wing rock for slender delta wings. IEEE Trans. Fuzzy Systems 12, 733–742 (2004)

Frayman, Y., Wang, L.P.: A Dynamically-constructed fuzzy neural controller for direct model reference adaptive control of multi-input-multi-output nonlinear processes. Soft Computing 6, 244–253 (2002)

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2005 Springer-Verlag Berlin Heidelberg

About this paper

Cite this paper

Zhang, Y.S., Chen, G.L. (2005). A Neuro-fuzzy Approach to Part Fitup Fault Control During Resistance Spot Welding Using Servo Gun. In: Wang, L., Chen, K., Ong, Y.S. (eds) Advances in Natural Computation. ICNC 2005. Lecture Notes in Computer Science, vol 3612. Springer, Berlin, Heidelberg. https://doi.org/10.1007/11539902_135

Download citation

DOI: https://doi.org/10.1007/11539902_135

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-540-28320-1

Online ISBN: 978-3-540-31863-7

eBook Packages: Computer ScienceComputer Science (R0)