Abstract

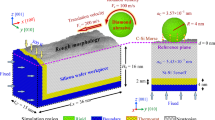

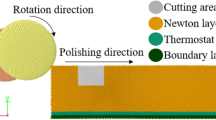

With the development of semiconductor industry, the chemical mechanical polishing technology has already become the mainstream method of realizing the surface global flatness. In order to understanding physical essence underlying this technology, the author carried out nanometer polishing experiment of silicon wafer using molecular dynamics (MD) simulation method. The simulation result shows that using larger slurry grain can generate much more vacancy, dislocation and larger residual stress than using of small one although using larger slurry grain can acquire better surface quality.

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

Han, X.S., Wang, S.X., Yu, S.Y.: Molecular Dynamics Simulation of Nanometric Grinding - The Effect of Crystal Anisotropy on the Quality of Machined Surface. Key Eng. Mater., 258–259, 361–365 (2004)

Han, X.S., Yu, S.Y.: Investigation of tool geometry in nanometric cutting by molecular dynamics simulation. J. Mater. Process Technol. 129(1-3), 105–108 (2002)

Yu, S.Y., Han, X.S.: A study on surface quality of ultraprecision grinding for engineering ceramics. Key Eng. Mater., 202–203, 35–39 (2001)

Liu, C.-W., Dai, B.-T., Tseng, W.-T.: Modeling of the wear mechanism during chemical-mechanical polishing. J. Electrochem. Soc. 143(2), 716–721 (1996)

Luo, J., Dornfeld, D.A.: Effects of abrasive size distribution in chemical mechanical planarization: Modeling and verification. IEEE Trans. Semicond. Manuf. 16(3), 469–476 (2006)

Morse, P.M.: Diatomic molecules according to the wave mechanics _ vibrational levels. Phys. Rev. 34, 57–65 (1929)

Tersoff, J.: Modeling solid state chemistry: Interatomic potential for multicomponent systems. Phys. Rev. B39, 5566–5570 (1989)

Belak, J., Boercher, D.B.: Molecular dynamics modeling of the mechanical behavior of metallic multilayers. In: Mater. Res. Soc. Symp. Proc., vol. 308, pp. 743–746 (1993)

Inamura, T., Shimada, S.: Brittle/ductile transition phenomena observed in computer simulations of machining defect-free monocrystalline silicon. CIRP 46(1), 31–34 (1997)

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2006 Springer-Verlag Berlin Heidelberg

About this paper

Cite this paper

Han, X. (2006). Investigation of Surface Integrity in the Case of Chemical Mechanical Polishing Silicon Wafer by Molecular Dynamics Simulation Method. In: Pan, Z., Cheok, A., Haller, M., Lau, R.W.H., Saito, H., Liang, R. (eds) Advances in Artificial Reality and Tele-Existence. ICAT 2006. Lecture Notes in Computer Science, vol 4282. Springer, Berlin, Heidelberg. https://doi.org/10.1007/11941354_67

Download citation

DOI: https://doi.org/10.1007/11941354_67

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-540-49776-9

Online ISBN: 978-3-540-49779-0

eBook Packages: Computer ScienceComputer Science (R0)