Abstract

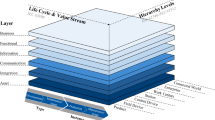

The digital revolution results in changes in the production and value-added processes, which is a challenge especially for SMEs who cannot keep up with the rapid pace of technology development. This is mainly due to the lack of know-how and lack of strategies to lead one’s own company into the fourth industrial revolution as well as high investment costs in industry 4.0 solutions with unclear benefits. The increased amount of data in production systems together with the increasing networking of all systems offer new possibilities for quality assurance and quality management, though. The main objective of Industry 4.0 out of the box is to enable manufacturing SMEs to carry out the individual tracking of value creation with minimal planning and implementation costs. Industry 4.0 out of the box contains all necessary hardware and software for flexible tracking of production and testing parameters at part level and the collection of order-specific parameters without disrupting normal production.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Plattform I4.0 Homepage. (2017). http://www.plattform-i40.de/I40/Navigation/DE/Industrie40/WasIndustrie40/was-ist-industrie-40.html. Last Accessed 12 Nov 2017.

IT-Innovation-Readiness-Index. (2015). Pierre Audoin Consultants (p. 13). München.

Kiem, R. (2016). Qualität 4.0: QM, MES und CAQ in digitalen Geschäftsprozessen der Industrie 4.0, p. 6. München: Carl Hanser Verlag GmbH & Co. KG.

Scheer, A. -W. (2013). Industrie 4.0—Wie sehen Produktionsprozesse im Jahr 2020 aus?, p. 15. Saarbrücken: Imc Information Multimedia Communication Ag.

Bajric, A., Mertins K., Rabe, M., & Jaekel, F. -W. (2010). A success story: Manufacturing execution system implementation. In The Proceeding of the 6th International Conference on Interoperability for Enterprise Software and Applications (IESA 2010), Springer, Coventry, UK.

INTEROP NOE. (2007). INTEROP, Enterprise Interoperability. Framework and knowledge corpus Final, FP6–Contact n 508011, Deliverable DI.3.

Naudet, Y., Guédria, W., & Chen, D.: Systems science for enterprise. In I-ESA’09 workshops, 5th International Conference.

Weinert, N., Plank, M., & Ullrich, A. (2017). Metamorphose zur intelligenten und vernetzten Fabrik: Ergebnisse des Verbundforschungsprojekts MetamoFAB. Berlin: Springer.

JUMP 40. (2017). Homepage. http://www.jump40.de. Last Accessed 12 Jan 2017.

Spur, G., Mertins, K., & Jochem, R. (1993). Integrierte Unternehmensmodellierung. Berlin: Beuth.

ISO 19440. (2007). Enterprise integration—constructs for enterprise modelling. Genève: ISO.

Industrial Internet Consortium. (2017). https://www.iiconsortium.org. Last Accessed 23 Nov 2017.

Plattform Industrie 4.0. (2017). http://www.plattform-i40.de. Last Accessed 23 Nov 2017.

OpenIoTFog Homepage. (2017). https://openiotfog.org. Last Accessed 23 Nov 2017.

Acknowledgements

This research and development project is funded by the European regional development fund. The author is responsible for the contents of this publication.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Switzerland AG

About this paper

Cite this paper

Gering, P., Drange, P. (2019). Industry 4.0 Out of the Box. In: Popplewell, K., Thoben, KD., Knothe, T., Poler, R. (eds) Enterprise Interoperability VIII. Proceedings of the I-ESA Conferences, vol 9. Springer, Cham. https://doi.org/10.1007/978-3-030-13693-2_4

Download citation

DOI: https://doi.org/10.1007/978-3-030-13693-2_4

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-13692-5

Online ISBN: 978-3-030-13693-2

eBook Packages: EngineeringEngineering (R0)