Abstract

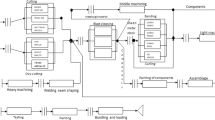

In the paper, the problem of proper resources management is considered. The problem was analysed and the results of a research on production improvement are presented, concerning specifically utilization rates of machinery and operators, as well as increase of production capacity. These aspects affect the efficiency of the whole production process. Thus, the proper resources management is an additional challenge that needs to be done by every manufacturing company. Examinations were carried-out in a company from the automotive industry, where the utilization of resources of three production lines were considered. In this case, the operators and machines utilization rates were emphasized. The optimization criteria was to increase the utilization rate of resources and reduce the time needed to produce one piece of each analysed products. The methods used to perform the improvement were, among the others, kanban and supermarket systems. The results were verified using computer simulation models designed for both present state and the state after implementing the suggested solutions.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Ratnayake, R.M.C., Stadnicka, D., Antosz, K.: Deriving an empirical model for machinery prioritization: mechanical systems maintenance. In: 2013 IEEE International Conference on Industrial Engineering and Engineering Management, Bangkok (2013)

Kotowska, J., Burduk, A.: Optimization of production support processes with the use of simulation tools. In: Wilimowska, Z., Borzemski, L., Świątek, J. (eds) Information Systems Architecture and Technology: Proceedings of 38th International Conference on Information Systems Architecture and Technology – ISAT 2017. Advances in Intelligent Systems and Computing, vol. 657, pp. 275–284 (2018)

Drevetskyi, V., Kovela, I., Kutia, V.: A method of comparative evaluation of control systems by the set of performance measures. Informatyka, Automatyka, Pomiary w Gospodarce i Ochronie Środowiska, vol. 3 (2017)

Kłos, S., Patalas-Maliszewska, J.: The topological impact of discrete manufacturing systems on the effectiveness of production processes. In: Rocha, Á., Correia, A., Adeli, H., Reis, L., Costanzo, S. (eds.) WorldCIST 2017. AISC, vol. 571, pp. 441–452. Springer, Cham (2017)

Grzybowska, K., Kovács, G.: The modelling and design process of coordination mechanisms in the supply chain. J. Appl. Logic 24, 25–38 (2017)

Krenczyk, D., Bocewicz, G.: Data-driven simulation model generation for ERP and DES systems integration. In: Jackowski, K., Burduk, R., Walkowiak, K., Wozniak, M., Yin, H. (eds) Intelligent Data Engineering and Automated Learning – IDEAL 2015. IDEAL 2015. Lecture Notes in Computer Science, vol 9375. Springer, Cham (2015)

Gwiazda, A., Sekala, A., Banas, W.: Modeling of a production system using the multiagent approach. In: Modtech International Conference - Modern Technologies in Industrial Engineering V, IOP Conference Series-Materials Science and Engineering, vol. 227 (2017)

Jasiulewicz-Kaczmarek, M.: The role of ergonomics in implementation of the social aspect of sustainability, illustrated with the example of maintenance. Occupational Safety and Hygiene, Occupational Safety and Hygiene, red. P. Arezes et al., CRC Press, Taylor & Francis Group, London (2013)

Rosienkiewicz, M., Gąbka, J., Helman, J., Kowalski, A., Susz, S.: Additive manufacturing technologies cost calculation as a crucial factor in industry 40. In: Hamrol, A., Ciszak, O., Legutko, S., Jurczyk, M. (eds.) Advances in Manufacturing. Lecture Notes in Mechanical Engineering. Springer, Cham (2018)

Kamińska, A.M., Parkitna, A., Górski, A.: Factors determining the development of small enterprises. In: Wilimowska, Z., Borzemski, L., Świątek, J. (eds) Information Systems Architecture and Technology: Proceedings of 38th International Conference on Information Systems Architecture and Technology – ISAT 2017. ISAT 2017. Advances in Intelligent Systems and Computing, vol 657. Springer, Cham (2018)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Switzerland AG

About this paper

Cite this paper

Górnicka, D., Kochańska, J., Burduk, A. (2020). Production Resources Utilization Improvement with the Use of Simulation Modelling. In: Świątek, J., Borzemski, L., Wilimowska, Z. (eds) Information Systems Architecture and Technology: Proceedings of 40th Anniversary International Conference on Information Systems Architecture and Technology – ISAT 2019. ISAT 2019. Advances in Intelligent Systems and Computing, vol 1051. Springer, Cham. https://doi.org/10.1007/978-3-030-30604-5_4

Download citation

DOI: https://doi.org/10.1007/978-3-030-30604-5_4

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-30603-8

Online ISBN: 978-3-030-30604-5

eBook Packages: Intelligent Technologies and RoboticsIntelligent Technologies and Robotics (R0)