Abstract

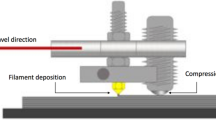

Additive Manufacturing Techniques such as Fused Filament Fabrication (FFF) produce 3D parts with complex geometries directly from a computer model without the need of using molding tools. Due to the rapid growth of these techniques, researchers have been increasingly interested in the availability of strategies, models or data that may assist process optimization. In fact, 3D parts often exhibit limited mechanical performance, which is usually the result of poor bonding between adjacent filaments. In turn, the latter is influenced by the temperature field history during deposition. This study aims at evaluating the influence of considering a phase change from the melt to the solid state on the heat transfer during the deposition stage, as undergone by semi-crystalline polymers. The energy equation considering solidification is solved analytically and then inserted in the MatLab® code previously developed by the authors to model cooling in FFF. The predictions of temperature evolution during the deposition of a simple 3D part demonstrate the importance of that thermal condition and highlight the influence of the type of material used for FFF.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Gebhardt, A.: Understanding Additive Manufacturing: Rapid Prototyping - Rapid Tooling - Rapid Manufacturing, 1st edn. Edition Hanser, Munich (2012)

Izdebska, J.: Printing on Polymers: Theory and Practice. In: Izdebska, J., Thomas, S. (eds.) Printing on Polymers: Fundamentals and Applications, pp. 1–20. William Andrew, Waltham (2016)

Rodríguez-Panes, A., Claver, J., Camacho, A.M.: The influence of manufacturing parameters on the mechanical behaviour of PLA and ABS pieces manufactured by FDM: a comparative analysis. Materials 11(8), 1–21 (2018)

Milde, J., Hrusecky, R., Zaujec, R., Morovic, L., Gorog, A.: Research of ABS and PLA materials in the process of fused deposition modeling method. In: Katalinic, B. (eds.) Proceedings of the 28th DAAAM International Symposium, Vienna, Austria, pp. 812–820. DAAM International (2017)

Kuznetsov, V.E., Solonin, A.N., Urzhumtsev, O.D., Schilling, R., Tavitov, A.G.: Strength of PLA components fabricated with fused deposition technology using a desktop 3D printer as a function of geometrical parameters of the process. Polymers 10(3), 313–323 (2018)

Hafsa, M., Ibrahim, M., Wahab, M., Zahid, M.: Evaluation of FDM pattern with ABS and PLA material. Appl. Mech. Mater. 465–466, 55–59 (2013)

Wojtyla, S., Klama, P., Baran, T.: Is 3D printing safe? Analysis of the thermal treatment of thermoplastics: ABS, PLA, PET, and nylon. J. Occup. Environ. Hyg. 14(6), 80–85 (2017)

Mudassir, A.: Measuring accuracy of two 3D Printing Materials, Department of Engineering Technologies. Bowling Green State University, Bowling Green (2016)

Sood, A.K., Ohdar, R.K., Mahapatra, S.S.: Parametric appraisal of mechanical property of fused deposition modelling processed parts. Mater. Des. 31, 287–295 (2010)

Sun, Q., Rizvi, G.M., Bellehumeur, C.T., Gu, P.: Effect of processing conditions on the bonding quality of FDM polymer filaments. Rapid Prototyping J. 14, 72–80 (2008)

Yang, F., Pitchumani, R.: Healing of thermoplastic polymers at an interface under nonisothermal conditions. Macromolecules 35, 3213–3224 (2002)

Costa, S.F., Duarte, F.M., Covas, J.A.: Estimation of filament temperature and adhesion development in fused deposition techniques. J. Mater. Process. Technol. 245, 167–179 (2017)

Costa, S.F., Duarte, F.M., Covas, J.A.: Thermal conditions affecting heat transfer in FDM/FFE: a contribution towards the numerical modelling of the process. Virtual Phys. Prototyping 10, 1–12 (2014)

Costa, S.F., Duarte, F.M., Covas, J.A.: An analytical solution for heat transfer during deposition in extrusion-based 3D printing techniques. In: Proceedings of the 15th International Conference Computational and Mathematical Methods in Science and Engineering, pp. 1161–1172 (2015)

Acknowledgments

This work has been supported by national funds through FCT – Fundação para a Ciência e Tecnologia through project UIDB/04728/2020.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Switzerland AG

About this paper

Cite this paper

Costa, S.F., Duarte, F.M., Covas, J.A. (2020). The Effect of a Phase Change During the Deposition Stage in Fused Filament Fabrication. In: Gervasi, O., et al. Computational Science and Its Applications – ICCSA 2020. ICCSA 2020. Lecture Notes in Computer Science(), vol 12249. Springer, Cham. https://doi.org/10.1007/978-3-030-58799-4_20

Download citation

DOI: https://doi.org/10.1007/978-3-030-58799-4_20

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-58798-7

Online ISBN: 978-3-030-58799-4

eBook Packages: Computer ScienceComputer Science (R0)