Abstract

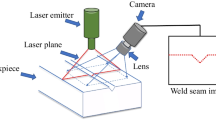

In this paper, a method for welding track correction based on emulational laser and trajectory are introduced. The proposed method is divided into two parts: seam tracking and trajectory correction. In the seam tracking method, by using the prior information of emulational laser stripes which are generated by the simulation software and affine transformation of emulational laser stripes, the real seam point can be detected. And then the trajectory correction method mainly consists of three steps: pre-processing, coarse matching and presice matching by using Iterative Closest Point Matching (ICP). For various conditions and workpieces, the corresponding experiments are conducted in this paper. Experimental results demonstrate that the method can meet the requirement of the internal seams tracking of workpiece and accuracy of welding track correction.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Yanling, X., Huanwei, Yu., Zhong, J., Lin, T., Chen, S.: Real-time seam tracking control technology during welding robot GTAW process based on passive vision sensor. J. Mater. Process. Technol. 212(8), 1654–1662 (2012)

Ma, H., Wei, S., Sheng, Z., Lin, T., Chen, S.: Robot welding seam tracking method based on passive vision for thin plate closed-gap butt welding. Int. J. Adv. Manuf. Technol. 48(9), 945–953 (2010). https://doi.org/10.1007/s00170-009-2349-4

Zhang, Y., Gao, X.: Analysis of characteristics of molten pool using cast shadow during high-power disk laser welding. Int. J. Adv. Manuf. Technol. 70(9), 1979–1988 (2013). https://doi.org/10.1007/s00170-013-5442-7

Xiao, R., Yanling, X., Hou, Z., Chen, C., Chen, S.: An adaptive feature extraction algorithm for multiple typical seam tracking based on vision sensor in robotic arc welding. Sensors Actuat. A Phys. 297, 111533 (2019)

Geng, J.: Structured-light 3D surface imaging: a tutorial. Adv. Optics Photon. 3(2), 128–160 (2011)

Fan, J., Jing, F., Yang, L., Long, T., Tan, M.: A precise seam tracking method for narrow butt seams based on structured light vision sensor. Opt. Laser Technol. 109, 616–626 (2019)

Zeng, J., et al.: A weld position recognition method based on directional and structured light information fusion in multi-layer/multi-pass welding. Sensors 18(1), 129 (2018)

Muhammad, J., Altun, H., Abo-Serie, E.: A robust butt welding seam finding technique for intelligent robotic welding system using active laser vision. Int. J. Adv. Manuf. Technol. 94(1), 13–29 (2016). https://doi.org/10.1007/s00170-016-9481-8

Gu, W.P., Xiong, Z.Y., Wan, W.: Autonomous seam acquisition and tracking system for multi-pass welding based on vision sensor. Int. J. Adv. Manuf. Technol. 69(1), 451–460 (2013). https://doi.org/10.1007/s00170-013-5034-6

Chen, X.Z., Chen, S.B.: The autonomous detection and guiding of start welding position for arc welding robot. Ind. Robot Int. J. 37(1), 70–78 (2010)

Huang, W., Kovacevic, R.: Development of a real-time laser-based machine vision system to monitor and control welding processes. Int. J. Adv. Manuf. Technol. 63(1), 235–248 (2012). https://doi.org/10.1007/s00170-012-3902-0

Yang, S.-M., Cho, M.-H., Lee, H.-Y., Cho, T.-D.: Weld line detection and process control for welding automation. Meas. Sci. Technol. 18(3), 819–826 (2007)

Xu, D., Jiang, Z., Wang, L., Tan, M.: Features extraction for structured light image of welding seam with arc and splash disturbance. In: ICARCV 2004 8th Control, Automation, Robotics and Vision Conference, 2004, vol. 3, pp. 1559–1563 (2004)

Chu, H.-H., Wang, Z.-Y.: A vision-based system for post-welding quality measurement and defect detection. Int. J. Adv. Manuf. Technol. 86(9), 3007–3014 (2016). https://doi.org/10.1007/s00170-015-8334-1

Kiddee, P., Fang, Z., Tan, M.: An automated weld seam tracking system for thick plate using cross mark structured light. Int. J. Adv. Manuf. Technol. 87, 3589–3603 (2016). https://doi.org/10.1007/s00170-016-8729-7

Ester, M., Kriegel, H.P., Sander, J., Xu, X.: A density-based algorithm for discovering clusters in large spatial databases with noise. In: Proceedings 1996 International Conference Knowledge Discovery and Data Mining (KDD 1996), pp. 226–231 (1996)

Besl, P.J., McKay, N.D.: Method for registration of 3-D shapes. Sensor Fusion IV Control Paradigms Data Struct. 1611, 586–606 (1992)

Acknowledgements

The authors would like to gratefully acknowledge the reviewers comments. This work is supported by National Natural Science Foundation of China (Grant Nos. U1713207 and 52075180), Science and Technology Program of Guangzhou (Grant Nos. 201904020020), and the Fundamental Research Funds for the Central Universities.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Switzerland AG

About this paper

Cite this paper

Wang, N., Yang, J., Zhong, K., Zhang, X. (2020). A Method for Welding Track Correction Based on Emulational Laser and Trajectory. In: Chan, C.S., et al. Intelligent Robotics and Applications. ICIRA 2020. Lecture Notes in Computer Science(), vol 12595. Springer, Cham. https://doi.org/10.1007/978-3-030-66645-3_42

Download citation

DOI: https://doi.org/10.1007/978-3-030-66645-3_42

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-66644-6

Online ISBN: 978-3-030-66645-3

eBook Packages: Computer ScienceComputer Science (R0)