Abstract

The transformation of industrial manufacturing with computers and automation with smart systems leads us to monitor and log of industrial equipment events. It is possible to apply analytic approaches, and to find interpretive results for strategic decision making, providing advantages such as failure detection and predictive maintenance.

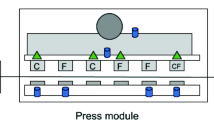

Over the last years, many researchers have been studying the application of machine learning techniques to improve such tasks. In this context, we develop a system capable of detect anomalies on an Air Production Unit (APU), taking into consideration the peak frequency of each sensor. The study started with the analysis of the sensors installed on the APU, defining its normal behavior and its failure mode. Using that information, we define rules, to monitor the APU, to detect anomalies on its components, and to predict possible failures. The definition of rules was based on the peak frequency analysis, which allowed the setting of boundaries of normality for the APU working modes and, thus, the identification of anomalies.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Allah Bukhsh, Z., Saeed, A., Stipanovic, I., Doree, A.G.: Predictive maintenance using tree-based classification techniques: a case of railway switches. Transp. Res. Part C Emerg. Technol. 101(February), 35–54 (2019). https://doi.org/10.1016/j.trc.2019.02.001

Aremu, O.O., Palau, A.S., Parlikad, A.K., Hyland-Wood, D., McAree, P.R.: Structuring data for intelligent predictive maintenance in asset management. IFAC-PapersOnLine 51(11), 514–519 (2018). https://doi.org/10.1016/j.ifacol.2018.08.370

Bengtsson, M.: Condition Based Maintenance Systems–An investigation of technical constituents and organizational aspects. Ph.D. thesis (2004)

De Benedetti, M., Leonardi, F., Messina, F., Santoro, C., Vasilakos, A.: Anomaly detection and predictive maintenance for photovoltaic systems. Neurocomputing 310, 59–68 (2018). https://doi.org/10.1016/j.neucom.2018.05.017

Fridolfsson, J., et al.: Effects of frequency filtering on intensity and noise in accelerometer-based physical activity measurements. Sensors 19(9), 2186 (2019). https://doi.org/10.3390/s19092186

Fumeo, E., Oneto, L., Anguita, D.: Condition based maintenance in railway transportation systems based on big data streaming analysis. Procedia Comput. Sci. 53, 437–446 (2015). https://doi.org/10.1016/j.procs.2015.07.321, http://www.sciencedirect.com/science/article/pii/S1877050915018244, iNNS Conference on Big Data 2015 Program San Francisco, CA, USA 8-10 August 2015

Hook, J.: Smoothing non-smooth systems with low-pass filters. Physica D: Nonlinear Phenomena 269, 76–85 (2014). https://doi.org/10.1016/j.physd.2013.11.016, http://www.sciencedirect.com/science/article/pii/S0167278913003254

Kang, S., Sristi, S., Karachiwala, J., Hu, Y.: Detection of anomaly in train speed for intelligent railway systems. In: 2018 International Conference Control Automation Diagnosis, ICCAD 2018 (2018)

Kennedy, R.: Examining the Processes of RCM and TPM: Group (January) 1–15 (2006)

Koons-Stapf, A.: Condition based maintenance: Theory, methodology, & application (2015)

Lee, W.J.: Anomaly detection and severity prediction of air leakage in train braking pipes. Int. J. Prognostics Health Manag. 21 (2017)

Lopes Gerum, P.C., Altay, A., Baykal-Gürsoy, M.: Data-driven predictive maintenance scheduling policies for railways. Transp. Res. Part C Emerg. Technol. 107(October 2018), 137–154 (2019). https://doi.org/10.1016/j.trc.2019.07.020

Manco, G., et al.: Fault detection and explanation through big data analysis on sensor streams. Expert Syst. Appl. 87, 141–156 (2017). https://doi.org/10.1016/J.ESWA.2017.05.079, https://www.sciencedirect.com/science/article/pii/S0957417417304074

Moubray, J.: Reliability-centered Maintenance. Industrial Press (2001). https://books.google.pt/books?id=bNCVF0B7vpIC

Pereira, P., Ribeiro, R.P., Gama, J.: Failure prediction – an application in the railway industry. In: Džeroski, S., Panov, P., Kocev, D., Todorovski, L. (eds.) DS 2014. LNCS (LNAI), vol. 8777, pp. 264–275. Springer, Cham (2014). https://doi.org/10.1007/978-3-319-11812-3_23

Rabatel, J., Bringay, S., Poncelet, P.: Anomaly detection in monitoring sensor data for preventive maintenance. Expert Syst. Appl. 38(6), 7003–7015 (2011). https://doi.org/10.1016/j.eswa.2010.12.014

Wang, Q., Zheng, S., Farahat, A., Serita, S., Gupta, C.: Remaining Useful Life Estimation Using Functional Data Analysis, April 2019

Acknowledgments

This research was Funded from national funds through FCT - Science and Technology Foundation, I.P in the context of the project FailStopper (DSAIPA /DS/0086/2018).

This work is financed by National Funds through the Portuguese funding agency, FCT - Fundação para a Ciência e a Tecnologia, within project UIDB/50014/ 2020.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Switzerland AG

About this paper

Cite this paper

Barros, M., Veloso, B., Pereira, P.M., Ribeiro, R.P., Gama, J. (2020). Failure Detection of an Air Production Unit in Operational Context. In: Gama, J., et al. IoT Streams for Data-Driven Predictive Maintenance and IoT, Edge, and Mobile for Embedded Machine Learning. ITEM IoT Streams 2020 2020. Communications in Computer and Information Science, vol 1325. Springer, Cham. https://doi.org/10.1007/978-3-030-66770-2_5

Download citation

DOI: https://doi.org/10.1007/978-3-030-66770-2_5

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-66769-6

Online ISBN: 978-3-030-66770-2

eBook Packages: Computer ScienceComputer Science (R0)