Abstract

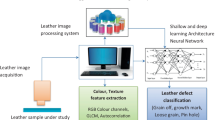

Smart production is trying to bring companies into the world of industry 4.0. In this field, leather is a natural product commonly used as a raw material to manufacture luxury objects. To ensure good quality on these products, one of the fundamental processes is the visual inspection phase to identify defects on leather surfaces. A typical exercise in quality control during the production is to perform a rigorous manual inspection on the same piece of leather several times, using different viewing angles and distances. However, the process of the human inspection is expensive, time-consuming, and subjective. In addition, it is always prone to human error and inter-subject variability as it requires a high level of concentration and might lead to labor fatigue. Therefore, there is a necessity to develop an automatic vision-based solution in order to reduce manual intervention in this specific process.

In this regard, this work presents an automatic approach to perform leather and stitching classification. The main goal is to automatically classify the images inside of a new dataset called LASCC (Leather And Stitching Color Classification) dataset. The dataset is newly collected and it is composed of 67 images with two different colors of leathers and seven different colors of stitching. For this purpose, Deep Convolutional Neural Networks (DCNNs) such as VGG16, Resnet50 and InceptionV3 have been applied to LASCC dataset, on a sample of 67 images.

Experimental results confirmed the effectiveness and the suitability of the approach, showing high values of accuracy.

This work was not supported by any organization.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

Notes

- 1.

LASCC Dataset is available upon request at the following link: https://vrai.dii.univpm.it/content/lascc-dataset.

References

Arivazhagan, S., Ganesan, L.: Texture classification using wavelet transform. Pattern Recogn. Lett. 24(9–10), 1513–1521 (2003)

Bong, H.Q., Truong, Q.B., Nguyen, H.C., Nguyen, M.T.: Vision-based inspection system for leather surface defect detection and classification. In: 2018 5th NAFOSTED Conference on Information and Computer Science (NICS), pp. 300–304. IEEE (2018)

Boser, B.E., Guyon, I.M., Vapnik, V.N.: A training algorithm for optimal margin classifiers. In: Proceedings of the Fifth Annual Workshop on Computational Learning Theory, pp. 144–152 (1992)

Brismar, J., Jacobsson, B.: Definition of terms used to judge the efficacy of diagnostic tests: a graphic approach. AJR Am. J. Roentgenol. 155(3), 621–623 (1990)

Broomhead, D.S., Lowe, D.: Radial basis functions, multi-variable functional interpolation and adaptive networks. Technical report, Royal Signals and Radar Establishment Malvern (United Kingdom) (1988)

Calabrese, M., et al.: Sophia: an event-based iot and machine learning architecture for predictive maintenance in industry 4.0. Information 11(4), 202 (2020)

Dasarathy, B.V.: Nearest neighbor (nn) norms: Nn pattern classification techniques. IEEE Computer Society Tutorial (1991)

Deng, J., Dong, W., Socher, R., Li, L.J., Li, K., Fei-Fei, L.: Imagenet: a large-scale hierarchical image database. In: 2009 IEEE Conference on Computer Vision and Pattern Recognition, pp. 248–255. IEEE (2009)

Giardina, C., Dougherty, E.: Morphological Methods in Image and Signal Processing, Prentice-Hall, Inc., New Jersey (1988)

He, K., Gkioxari, G., Dollár, P., Girshick, R.: Mask r-cnn. In: Proceedings of the IEEE International Conference on Computer Vision, pp. 2961–2969 (2017)

He, K., Zhang, X., Ren, S., Sun, J.: Deep residual learning for image recognition. In: Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, pp. 770–778 (2016)

Jawahar, M., Babu, N.C., Vani, K.: Leather texture classification using wavelet feature extraction technique. In: 2014 IEEE International Conference on Computational Intelligence and Computing Research, pp. 1–4. IEEE (2014)

Jobanputra, R., Clausi, D.A.: Texture analysis using gaussian weighted grey level co-occurrence probabilities. In: First Canadian Conference on Computer and Robot Vision, 2004. Proceedings, pp. 51–57. IEEE (2004)

Keerthi, S.S., Lin, C.J.: Asymptotic behaviors of support vector machines with gaussian kernel. Neural Comput. 15(7), 1667–1689 (2003)

Kingma, D.P., Ba, J.: Adam: A method for stochastic optimization. arXiv preprint arXiv:1412.6980 (2014)

Krizhevsky, A., Sutskever, I., Hinton, G.E.: Imagenet classification with deep convolutional neural networks. In: Advances in Neural Information Processing Systems, pp. 1097–1105 (2012)

Lasi, H., Fettke, P., Kemper, H.G., Feld, T., Hoffmann, M.: Industry 4.0. Bus. Inform. Syst. Eng. 6(4), 239–242 (2014)

Lee, C., Wong, S.: A mathematical morphological approach for segmenting heavily noise-corrupted images. Pattern Recogn. 29(8), 1347–1358 (1996)

Lee, J., Kao, H.A., Yang, S., et al.: Service innovation and smart analytics for industry 4.0 and big data environment. Procedia Cirp. 16(1), 3–8 (2014)

Liong, S.T., Gan, Y., Huang, Y.C., Yuan, C.A., Chang, H.C.: Automatic defect segmentation on leather with deep learning. arXiv preprint arXiv:1903.12139 (2019)

Liong, S.T., et al.: Efficient neural network approaches for leather defect classification. arXiv preprint arXiv:1906.06446 (2019)

Lovergine, F.P., Branca, A., Attolico, G., Distante, A.: Leather inspection by oriented texture analysis with a morphological approach. In: Proceedings of International Conference on Image Processing, vol. 2, pp. 669–671. IEEE (1997)

Lu, Y., Xu, X., Xu, J.: Development of a hybrid manufacturing cloud. J. Manufact. Syst. 33(4), 551–566 (2014)

Paolanti, M., Frontoni, E.: Multidisciplinary pattern recognition applications: a review. Comput. Sci. Rev. 37, 100276 (2020)

Paolanti, M., Pietrini, R., Mancini, A., Frontoni, E., Zingaretti, P.: Deep understanding of shopper behaviours and interactions using rgb-d vision. Mach. Vis. Appl. 31(7), 1–21 (2020)

Paolanti, M., Romeo, L., Felicetti, A., Mancini, A., Frontoni, E., Loncarski, J.: Machine learning approach for predictive maintenance in industry 4.0. In: 2018 14th IEEE/ASME International Conference on Mechatronic and Embedded Systems and Applications (MESA), pp. 1–6. IEEE (2018)

Pereira, R.F., Dias, M.L., de Sá Medeiros, C.M., Rebouças Filho, P.P.: Classification of failures in goat leather samples using computer vision and machine learning

Pistori, H., Paraguassu, W.A., Martins, P.S., Conti, M.P., Pereira, M.A., Jacinto, M.A.: Defect detection in raw hide and wet blue leather. In: Proceedings of the International Symposium Computing IMAGE, p. 355 (2018)

Powers, D.M.: Evaluation: from precision, recall and f-measure to roc, informedness, markedness and correlation (2011)

Romeo, L., Loncarski, J., Paolanti, M., Bocchini, G., Mancini, A., Frontoni, E.: Machine learning-based design support system for the prediction of heterogeneous machine parameters in industry 4.0. Expert Syst. Appl. 140, 112869 (2020)

Romeo, L., Paolanti, M., Bocchini, G., Loncarski, J., Frontoni, E.: An innovative design support system for industry 4.0 based on machine learning approaches. In: 2018 5th International Symposium on Environment-Friendly Energies and Applications (EFEA), pp. 1–6. IEEE (2018)

Simonyan, K., Zisserman, A.: Very deep convolutional networks for large-scale image recognition. arXiv preprint arXiv:1409.1556 (2014)

Sokolova, M., Lapalme, G.: A systematic analysis of performance measures for classification tasks. Inform. Process. Manag. 45(4), 427–437 (2009)

Sturari, M., Paolanti, M., Frontoni, E., Mancini, A., Zingaretti, P.: Robotic platform for deep change detection for rail safety and security. In: 2017 European Conference on Mobile Robots (ECMR), pp. 1–6. IEEE (2017)

Szegedy, C., et al.: Going deeper with convolutions. In: Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, pp. 1–9 (2015)

Szegedy, C., Vanhoucke, V., Ioffe, S., Shlens, J., Wojna, Z.: Rethinking the inception architecture for computer vision. In: Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, pp. 2818–2826 (2016)

Wang, L., Törngren, M., Onori, M.: Current status and advancement of cyber-physical systems in manufacturing. J. Manufact. Syst. 37, 517–527 (2015)

Wang, P., Gao, R.X., Fan, Z.: Cloud computing for cloud manufacturing: benefits and limitations. J. Manufact. Sci. Eng. 137(4) (2015)

Winiarti, S., Prahara, A., Murinto, D.P.I., Ismi, P.: Pretrained convolutional neural network for classification of tanning leather image. Network (CNN), vol. 9, no. 1 (2018)

Wu, D., Rosen, D.W., Schaefer, D.: Cloud-based design and manufacturing: status and promise. In: Cloud-Based Design and Manufacturing (CBDM), pp. 1–24. Springer, Berlin (2014)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 Springer Nature Switzerland AG

About this paper

Cite this paper

Pazzaglia, G., Martini, M., Rosati, R., Romeo, L., Frontoni, E. (2021). A Deep Learning-Based Approach for Automatic Leather Classification in Industry 4.0. In: Del Bimbo, A., et al. Pattern Recognition. ICPR International Workshops and Challenges. ICPR 2021. Lecture Notes in Computer Science(), vol 12664. Springer, Cham. https://doi.org/10.1007/978-3-030-68799-1_48

Download citation

DOI: https://doi.org/10.1007/978-3-030-68799-1_48

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-68798-4

Online ISBN: 978-3-030-68799-1

eBook Packages: Computer ScienceComputer Science (R0)