Abstract

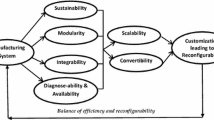

The reconfigurable manufacturing system (RMS) is one of the newest manufacturing paradigms. In this paradigm, machine components, machine software, or handling units can be inserted, removed, modified, or interchanged as needed and, where appropriate, imposed by the need to adapt and adjust quickly and cost-effectively to changing requirements. RMS is considered to be a convenient processing paradigm for the manufacture of varieties as well as a scalable enabler for this variety. Considered as two of the six main RMS characteristics, in this paper, we review the most used models and solving approaches dedicated to scalability and convertibility in reconfigurable manufacturing environments. Moreover, we highlight the most critical research gaps.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Koren, Y., et al.: Reconfigurable manufacturing systems. CIRP Ann. 48(2), 527–540 (1999)

Koren, Y. (2006) General RMS characteristics. comparison with dedicated and flexible systems. In: Dashchenko, A.I. (eds.) Reconfigurable Manufacturing Systems and Transformable Factories, pp. 27–45. Springer, Berlin, Heidelberg (2006). https://doi.org/10.1007/3-540-29397-3_3

Koren, Y., Gu, X., Badurdeen, F., Jawahir, I.S.: Sustainable living factories for next generation manufacturing. Procedia Manuf. 21, 26–36 (2018)

Koren, Y.: The emergence of reconfigurable manufacturing systems (RMSs). In: Benyoucef, L. (ed.) Reconfigurable Manufacturing Systems: From Design to Implementation. SSAM, pp. 1–9. Springer, Cham (2020). https://doi.org/10.1007/978-3-030-28782-5_1

Son, S., Lennon Olsen, T., Yip-Hoi, D.: An approach to scalability and line balancing for reconfigurable manufacturing systems. Integr. Manuf. Syst. 12(7), 500–511 (2001)

Deif, A.M., ElMaraghy, H.A.: Assessing capacity scalability policies in RMS using system dynamics. Int. J. Flex. Manuf. Syst. 19(3), 128–150 (2007)

Deif, A.M., ElMaraghy, W.H.: A control approach to explore the dynamics of capacity scalability in reconfigurable manufacturing systems. J. Manuf. Syst. 25(1), 12–24 (2006)

Deif, A.M., ElMaraghy, W.H.: Integrating static and dynamic analysis in studying capacity scalability in RMS. Int. J. Manuf. Res. 2(4), 414–427 (2007)

Wang, W., Koren, Y.: Design principles of scalable reconfigurable manufacturing systems. IFAC Proceedings Volumes 46(9), 1411–1416 (2013)

Hasan, S.M., Baqai, A.A., Butt, S.U., Ausaf, M.F., Zaman, U.: Incorporation of part complexity into system scalability for flexible/reconfigurable systems. Int. J. Adv. Manuf. Technol. 99(9), 2959–2929 (2018). https://doi.org/10.1007/s00170-018-2654-x

Koren, Y., Wang, W., Gu, X.: Value creation through design for scalability of reconfigurable manufacturing systems. Int. J. Prod. Res. 55(5), 1227–1242 (2017)

Asl, F.M., Galip Ulsoy, A..: Stochastic optimal capacity management in reconfigurable manufacturing systems. J. Manuf. Sci. Product. 6(1–2), 83–88 (2004)

Maler-Speredelozzi, V., Koren, Y., Hu, S.J.: Convertibility measures for manufacturing systems. CIRP Ann. 52(1), 367–370 (2003)

Gumasta, K., Gupta, S.K., Benyoucef, L., Tiwari, M.K.: Developing a reconfigurability index using multi-attribute utility theory. Int. J. Prod. Res. 49(6), 1669–1683 (2011)

Goyal, K.K., Jain, P K., Jain, M.: Multiple objective optimization of reconfigurable manufacturing system. In :Advances in Intelligent and Soft Computing, pp. 453–460. Springer India (2012)

Mittal, K.K., Jain, P.K., Kumar, D.: Optimal configuration selection in reconfigurable manufacturing system. In: Deep, K., Jain, M., Salhi, S. (eds.) Decision Science in Action. AA, pp. 193–202. Springer, Singapore (2019). https://doi.org/10.1007/978-981-13-0860-4_14

Lafou, M., Mathieu, L., Pois, S., Alochet, M.: convertibility indicator for manual mixed-model assembly lines. Procedia CIRP 17, 314–319 (2014)

Chinnathai, M.K., Alkan, B., Harrison, R.: Convertibility evaluation of automated assembly system designs for high variety production. Procedia CIRP 60, 74–79 (2017)

Wang, W., Koren, Y.: Scalability planning for reconfigurable manufacturing systems. J. Manuf. Syst. 31(2), 83–91 (2012)

Elmasry, S.S., Youssef, A.M.A., Shalaby, M.A.: Investigating best capacity scaling policies for different reconfigurable manufacturing system scenarios. Procedia CIRP 17, 410–415 (2014)

Wang, W., Koren, Y.: design principles of scalable reconfigurable manufacturing systems. IFAC Proc. 46(9), 1411–1416 (2013)

Elmasry, S.S., Youssef, A.M.A., Shalaby, M.A.: A cost-based model to select best capacity scaling policy for reconfigurable manufacturing systems. Int. J. Manuf. Res. 10(2), 162–183 (2015)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 IFIP International Federation for Information Processing

About this paper

Cite this paper

Dahmani, A., Benyoucef, L. (2021). Scalability and Convertibility Models and Approaches for Reconfigurable Manufacturing Environments. In: Dolgui, A., Bernard, A., Lemoine, D., von Cieminski, G., Romero, D. (eds) Advances in Production Management Systems. Artificial Intelligence for Sustainable and Resilient Production Systems. APMS 2021. IFIP Advances in Information and Communication Technology, vol 631. Springer, Cham. https://doi.org/10.1007/978-3-030-85902-2_47

Download citation

DOI: https://doi.org/10.1007/978-3-030-85902-2_47

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-85901-5

Online ISBN: 978-3-030-85902-2

eBook Packages: Computer ScienceComputer Science (R0)