Abstract

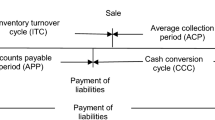

Cash flow bullwhip effect (CFB) is the amplification of working capital variance along a supply chain. High CFB is a sign of inefficient working capital (WC) management and can lead to a significant reduction in financial resilience. CFB can be used as a measure of a company’s ability to manage operational risks and corresponding resilience. We investigate the existence of CFB and the traditional bullwhip effect (BWE) in a sample of 238 semiconductor companies over 2010-Q1 to 2020-Q4. These companies' average CFB and BWE are 3.95 and 2.77, respectively. We find that CFB and BWE of a semiconductor company are negatively associated with company size, degree of seasonality in demand, and company’s payment policy conservativeness; and positively associated with procurement and payment lead times.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Tangsucheeva, R., Prabhu, V.: Modeling and analysis of cash-flow bullwhip in supply chain. Int. J. Prod. Econ. 145, 431–447 (2013). https://doi.org/10.1016/j.ijpe.2013.04.054

Hofmann, E., Kotzab, H.: A supply chain-oriented approach of working capital management. J. Bus. Logist. 31, 305–330 (2010). https://doi.org/10.1002/j.2158-1592.2010.tb00154.x

Peng, J., Zhou, Z.: Working capital optimization in a supply chain perspective. Eur. J. Oper. Res. 277, 846–856 (2019). https://doi.org/10.1016/j.ejor.2019.03.022

Pirttilä, M., Virolainen, V.M., Lind, L., Kärri, T.: Working capital management in the Russian automotive industry supply chain. Int. J. Prod. Econ. 221, 107474 (2020). https://doi.org/10.1016/j.ijpe.2019.08.009

Lamzaouek, H., Drissi, H., El Haoud, N.: Cash flow bullwhip—literature review and research perspectives. In: Logist 2021, vol. 5, p. 8 5:8 (2021). https://doi.org/10.3390/LOGISTICS5010008

Ivanov, D.: Supply chain management and structural dynamics control. In: Structural Dynamics and Resilience in Supply Chain Risk Management. International Series in Operations Research & Management Science (ISOR), vol. 265. Springer, Cham (2018). https://doi.org/10.1007/978-3-319-69305-7_1

Dominguez, R., Cannella, S., Framinan, J.M.: On bullwhip-limiting strategies in divergent supply chain networks. Comput. Ind. Eng. 73, 85–95 (2014). https://doi.org/10.1016/j.cie.2014.04.008

Wang, X., Disney, S.M.: The bullwhip effect: progress, trends and directions. Eur. J. Oper. Res. 250, 691–701 (2016)

Patil, C., Prabhu, V.: Working capital distress caused by supply chain cash-flow bullwhip. Working paper (2021)

Chen, F., Drezner, Z., Ryan, J.K., Simchi-Levi, D.: Quantifying the bullwhip effect in a simple supply chain: the impact of forecasting, lead times, and information. Manage. Sci. 46, 436–443 (2000). https://doi.org/10.1287/mnsc.46.3.436.12069

Cachon, G.P., Randall, T., Schmidt, G.M.: In search of the bullwhip effect. Manuf. Serv. Oper. Manag. 9, 457–479 (2007). https://doi.org/10.1287/msom.1060.0149

Mönch, L., Chien, C.F., Dauzère-Pérès, S., et al.: Modelling and analysis of semiconductor supply chains. Int. J. Prod. Res. 56, 4521–4523 (2018)

Chen, Y.J., Chien, C.F.: An empirical study of demand forecasting of non-volatile memory for smart production of semiconductor manufacturing. Int. J. Prod. Res. 56, 4629–4643 (2018). https://doi.org/10.1080/00207543.2017.1421783

Vanek, F., Sun, Y.: Transportation versus perishability in life cycle energy consumption: a case study of the temperature-controlled food product supply chain. Transp. Res. Part D Transp. Environ. 13, 383–391 (2008). https://doi.org/10.1016/j.trd.2008.07.001

Ravindran, A.R., Warsing, D., Jr.: Supply Chain Engineering: Models and Applications. CRC Press, Boca Raton (2016)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 IFIP International Federation for Information Processing

About this paper

Cite this paper

Patil, C., Prabhu, V.V. (2021). Cash-Flow Bullwhip Effect in the Semiconductor Industry: An Empirical Investigation. In: Dolgui, A., Bernard, A., Lemoine, D., von Cieminski, G., Romero, D. (eds) Advances in Production Management Systems. Artificial Intelligence for Sustainable and Resilient Production Systems. APMS 2021. IFIP Advances in Information and Communication Technology, vol 631. Springer, Cham. https://doi.org/10.1007/978-3-030-85902-2_8

Download citation

DOI: https://doi.org/10.1007/978-3-030-85902-2_8

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-85901-5

Online ISBN: 978-3-030-85902-2

eBook Packages: Computer ScienceComputer Science (R0)