Abstract

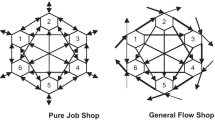

The traditional configurations of market response, make-to-order (MTO) and make-to-stock (MTS), are no more suitable in today’s competitive context, forcing companies to a transition towards hybrid solutions. Unfortunately, this has been neglected, in particular at the operational level where the Order Review and Release issue counts only two related articles but restricted to job shops. Therefore, researchers are moving towards flow shop configuration, particularly addressing the issue of bottleneck. Literature links this topic to the Theory of Constraints by Goldratt and Cox [14], from which Drum Buffer Rope (DBR) has been designed as a production planning and control tool. The objective of this paper has been defined as verifying how the decision on the release model changes considering the designed hybrid flow shop model. Simulation results are not clearly in favor of one over the other, since besides severity, there is another important factor to consider: the choice of control at dispatching level, and its connected trade-offs. In particular, implementing this control with bottleneck-based rule is effective for MTO performances, especially in case of high severity. Instead, when control at dispatching is absent, the workload control as release rule is preferred, leading also to the best lead times for low severity.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Francas, D., Löhndorf, N., Minner, S.: Machine and labor flexibility in manufacturing networks. Int. J. Prod. Econ. 131(1), 165–174 (2011)

Kingsman, B., Hendry, L., Mercer, A., De Souza, A.: Responding to customer enquiries in make-to-order companies problems and solutions. Int. J. Prod. Econ. 46–47, 219–231 (1996)

Kingsman, B., Hendry, L.: The relative contributions of input and output controls on the performance of a workload control system in make-to-order companies. Prod. Plan. Control 13(7), 579–590 (2002)

Kundu, K., Land, M.J., Portioli-Staudacher, A., Bokhorst, J.A.: Order review and release in make-to-order flow shops: analysis and design of new methods. Flex. Serv. Manuf. J., 1–33 (2020).https://doi.org/10.1007/s10696-020-09392-6

Rossini, M., Audino, F., Costa, F., Cifone, F.D., Kundu, K., Portioli-Staudacher, A.: Extending lean frontiers: a Kaizen case study in an Italian MTO manufacturing company. Int. J. Adv. Manuf. Technol. 104(5–8), 1869–1888 (2019). https://doi.org/10.1007/s00170-019-03990-x

Eivazy, H., Rabbani, M.: A novel production control model for manufacturing systems with pure MTS, pure MTO, and hybrid MTS-MTO products. In: 2009 International Conference on Computers and Industrial Engineering, CIE 2009 (2009)

Fernandes, N.O., Gomes, M., Carmo-Silva, S.: Workload control and order release in combined MTO-MTS production. Rom. Rev. Prec. Mech. Opt. Mechatron. 43, 33–39 (2013)

Małachowski, B., Korytkowski, P.: Competence-based performance model of multi-skilled workers. Comput. Ind. Eng. 91, 165–177 (2016)

Soman, C.A., Van Donk, D.P., Gaalman, G.: Combined make-to-order and make-to-stock in a food production system. Int. J. Prod. Econ. 90(2), 223–235 (2004)

Eivazy, H., Rabbani, M., Ebadian, M.: A developed production control and scheduling model in the semiconductor manufacturing systems with hybrid make-to-stock/make-to-order products. Int. J. Adv. Manuf. Tech. 45(9), 968–986 (2009)

Thürer, M., Stevenson, M., Silva, C., Qu, T.: Drum-buffer-rope and workload control in high-variety flow and job shops with bottlenecks: an assessment by simulation. Int. J. Prod. Econ. 188, 116–127 (2017)

Thürer, M., Stevenson, M.: Bottleneck-oriented order release with shifting bottlenecks: an assessment by simulation. Int. J. Prod. Econ. 197, 275–282 (2018)

Ashcroft, S.H.: Applying the principles of optimized production technology in a small manufacturing company. Eng. Cost. Prod. Econ. 17(1–4), 79–88 (1989)

Goldratt, E.M., Cox, J.: The Goal: A Process of Ongoing Improvement. North River Press, Croton-on-Hudson, NY (1984)

Thürer, M., Stevenson, M.: On the beat of the drum: improving the flow shop performance of the Drum–Buffer–Rope scheduling mechanism. Int. J. Prod. Res. 56(9), 3294–3305 (2018)

Thürer, M., Qu, T., Stevenson, M., Li, C.D., Huang, G.Q.: Deconstructing bottleneck shiftiness: the impact of bottleneck position on order release control in pure flow shops. Prod. Plan. Control 28(15), 1223–1235 (2017)

Spearman, M.L., Woodruff, D.L., Hopp, W.J.: CONWIP: a pull alternative to Kanban. Int. J. Prod. Res. 28(5), 879–894 (1990)

Framinan, J.M., González, P.L., Ruiz-Usano, R.: The CONWIP production control system: review and research issues. Prod. Plan. Control 14(3), 255–265 (2003)

Hopp, W., Spearman, M.: Basic factory dynamics. In: Factory Physics: Foundations of Manufacturing Management (1996)

Herer, Y.T., Masin, M.: Mathematical programming formulation of CONWIP based production lines; and relationships to MRP. Int. J. Prod. Res. 35(4), 1067–1076 (1997)

Spearman, M.L., Hopp, W.J., Woodruff, D.L.: A hierarchical control architecture for Constant Work-in-Process (CONWIP) production systems. J. Manuf. Opers. Manag. 2, 147–171 (1989)

Portioli-Staudacher, A., Costa, F., Thürer, M.: The use of labour flexibility for output control in workload controlled flow shops: a simulation analysis. Int. J. Ind. Eng. Comput. 11(3), 429–442 (2020)

Kundu, K., Rossini, M., Portioli-Staudacher, A.: Analysing the impact of uncertainty reduction on WLC methods in MTO flow shops. Prod. Manuf. Res. 6(1), 328–344 (2018)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 IFIP International Federation for Information Processing

About this paper

Cite this paper

Costa, F., Kundu, K., Portioli-Staudacher, A. (2021). An Assessment of Order Release Models in Hybrid MTO-MTS Flow Shop with Bottleneck. In: Dolgui, A., Bernard, A., Lemoine, D., von Cieminski, G., Romero, D. (eds) Advances in Production Management Systems. Artificial Intelligence for Sustainable and Resilient Production Systems. APMS 2021. IFIP Advances in Information and Communication Technology, vol 634. Springer, Cham. https://doi.org/10.1007/978-3-030-85914-5_30

Download citation

DOI: https://doi.org/10.1007/978-3-030-85914-5_30

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-85913-8

Online ISBN: 978-3-030-85914-5

eBook Packages: Computer ScienceComputer Science (R0)