Abstract

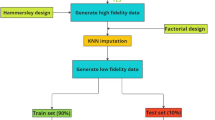

Welding residual stress (WRS) estimation is highly nonlinear process due to its association with high thermal gradients generated during welding. Accurate and fast estimation of welding induced residual stresses in critical weld geometries of offshore structures, piping components etc., becomes important from structural integrity perspective. Fitness for services (FFS) codes like API 579, BS7910 recommend residual stress profiles are mainly based on three approaches, out of which nonlinear finite element modelling (FEM) results coupled with residual stress experimental measurement, have been found to be most conservative and realistic. The residual stress estimation from thermo mechanical FEM models is computationally expensive as it involves a large degree of interactions between thermal, mechanical, metallurgical and phase transformations etc. The destructive and non-destructive measurement techniques also carry a large amount of uncertainly due to lack of standardization and interpretation variability of measurement results. To mitigate the aforementioned challenges, response surface models (RSMs) have been proposed in this study, for the estimation of WRS at a significant confidence. This paper examines the applicability of 12 different Response Surface Models (RSMs) for estimating WRS. The training and testing data is generated using FEM, Abaqus - 2D weld interface (AWI) plug-in. To compare the accuracy of the RSMs, three metrics, namely, Root Mean Square Error (RMSE), Maximum Absolute Error (AAE), and Explained Variance Score (EVS) are used. An illustrative case study to demonstrate the applicability of the response surface model to predict WRS is also presented.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Bhardwaj, S., Ratnayake, R.M.C.: Challenges due to welds fabricated at a close proximity on offshore structures, pipelines, and piping: state of the art. In: ASME 2020 39th International Conference on Ocean, Offshore and Arctic Engineering (2020)

Bhardwaj, S., et al.: Machine learning approach for estimating residual stresses in girth welds of topside piping. In: ASME 2020 39th International Conference on Ocean, Offshore and Arctic Engineering (2020)

Bhatti, A.A., Barsoum, Z., Khurshid, M.: Development of a finite element simulation framework for the prediction of residual stresses in large welded structures. Comput. Struct. 133, 1–11 (2014)

Dong, P., et al.: On residual stress prescriptions for fitness for service assessment of pipe girth welds. Int. J. Press. Vessels Pip. 123–124, 19–29 (2014)

Dong, P.: Residual stresses and distortions in welded structures: a perspective for engineering applications. Sci. Technol. Weld. Joining 10(4), 389–398 (2005)

Ficquet, X., et al.: Measurement and prediction of residual stress in a bead-on-plate weld benchmark specimen. Int. J. Press. Vessels Pip. 86(1), 20–30 (2009)

Francis, J.A., Bhadeshia, H.K.D.H., Withers, P.J.: Welding residual stresses in ferritic power plant steels. Mater. Sci. Technol. 23(9), 1009–1020 (2007)

Institute, A.P., API RP 579-1/ASME FFS-1. Houston, TX: American Petroleum Institute; USA, August 2007 (2007)

Brownlee, J.: A gentle introduction to the gradient boosting algorithm for machine learning (2020). http://machinelearningmastery.com/gentle-introduction-gradient-boosting-algorithm-machine-learning/. Accessed 30 Aug 2021

Keprate, A., Ratnayake, R.M.: Using gradient boosting regressor to predict stress intensity factor of a crack propagating in small bore piping (2017)

Keprate, A., Ratnayake, R.M.C., Sankararaman, S.: Comparing different metamodelling approaches to predict stress intensity factor of a semi-elliptic crack. In: ASME 2017 36th International Conference on Ocean, Offshore and Arctic Engineering (2017)

Mirzaee-Sisan, A., Wu, G.: Residual stress in pipeline girth welds- a review of recent data and modelling. Int. J. Press. Vessels Pip. 169, 142–152 (2019)

Smith, M.C., et al.: A review of the NeT Task Group 1 residual stress measurement and analysis round robin on a single weld bead-on-plate specimen. Int. J. Press. Vessels Pip. 120–121, 93–140 (2014)

Song, S., Pei, X., Dong, P.: An analytical interpretation of welding linear heat input for 2D residual stress models. In: ASME 2015 Pressure Vessels and Piping Conference (2015)

Standard, B.: BS 7910 Guide to methods for assessing the acceptability of flaws in metallic structures, UK (2019)

Ueda, Y., Murakawa, H., Ma, N.: Introduction to measurement and prediction of residual stresses with the help of inherent strains. In: Ueda, Y., Murakawa, H., Ma, N. (eds.) Welding Deformation and Residual Stress Prevention, pp. 35–53. Butterworth-Heinemann, Boston (2012)

Withers, P.J., Bhadeshia, H.K.D.H.: Residual stress. Part 2 – Nature and origins. Mater. Sci. Technol. 17(4), 366–375 (2001)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Bhardwaj, S., Keprate, A., Ratnayake, R.M.C. (2022). Residual Stress Prediction of Welded Joints Using Gradient Boosting Regression. In: Sanfilippo, F., Granmo, OC., Yayilgan, S.Y., Bajwa, I.S. (eds) Intelligent Technologies and Applications. INTAP 2021. Communications in Computer and Information Science, vol 1616. Springer, Cham. https://doi.org/10.1007/978-3-031-10525-8_4

Download citation

DOI: https://doi.org/10.1007/978-3-031-10525-8_4

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-10524-1

Online ISBN: 978-3-031-10525-8

eBook Packages: Computer ScienceComputer Science (R0)