Abstract

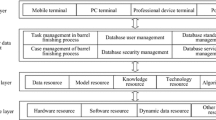

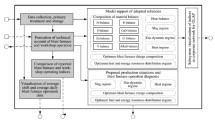

Blisks with integral structure are key component of the power system. Blade profile usually possesses high complexity and is hard to be milled. There are problems of vague data system and low interconnection in the process information management, which seriously impedes the improvement of the intelligence of milling process. This paper presents a modular information schema in the view of machining features, and the data integration model of blade milling process information is established. Furthermore, the composition of blade milling process database is proposed. Take the advantage of the CAM software specially for 5-axis milling blade and relational database technology, a prototype software system for data management of blade milling process, which is able to realize the function of automatic extraction, storage, and correlation interaction for relevant process data, is developed. It has been tested and verified that the data management model and prototype system are feasible and available by collecting and storing the process data of some simulated blade profiles. The work in this paper can be accepted as a technical support to the integrating information management, and the machining efficiency improvement of intelligent milling unit for the complex blade parts.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

González-Barrio, H., Calleja-Ochoa, A., Lamikiz, A.: Manufacturing processes of integral blade rotors for turbomachinery, processes and new approaches. Appl. Sci. 10(9), 3063 (2020)

Nandakumar, S., Shah, J.J.: Recognition of multi axis milling features: Part I-topological and geometric characteristics. J. Comput. Inf. Sci. Eng. 4(3), 242–250 (2004)

Nandakumar, S., Shah, J.J.: Recognition of multi-axis milling features: Part II—algorithms & implementation. J. Comput. Inf. Sci. Eng. 5(1), 25–34 (2005)

Ma, H., Zhou, X., Liu, W., Li, J., Niu, Q., Kong, C.: A feature-based approach towards integration and automation of CAD/CAPP/CAM for EDM electrodes. Int. J. Adv. Manuf. Technol. 98(9–12), 2943–2965 (2018). https://doi.org/10.1007/s00170-018-2447-2

Huang, R., Zhang, S., Bai, X.: Multi-level structuralized model-based definition model based on machining features for manufacturing reuse of mechanical parts. Int. J. Adv. Manuf. Technol. 75, 1035–1048 (2014)

Deja, M., Siemiatkowski, M.S.: Machining process sequencing and machine assignment in generative feature-based CAPP for mill-turn parts. J. Manuf. Syst. 48, 49–62 (2018)

Liang, Y., Zhang, D., Ren, J., Chen, Z.C., Xu, Y.: Accessible regions of tool orientations in multi-axis milling of blisks with a ball-end mill. Int. J. Adv. Manuf. Technol. 85(5–8), 1887–1900 (2016). https://doi.org/10.1007/s00170-016-8356-3

Brecher, C., Lohse, W.: Evaluation of toolpath quality: user-assisted CAM for complex milling processes. CIRP J. Manuf. Sci. Technol. 6(4), 233–245 (2013)

Zhang, N., Shi, Y., Yang, C.: Multi-objective optimization of processing parameters for disc-mill cutter machining blisk-tunnel based on GRA-RBF-FA method. J. Northwest. Polytech. Univ. 37(1), 160–166 (2019)

Acknowledgements

This work is supported by the National Natural Science Foundation of China (Grant No. 51875312).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Liu, S., Zhao, T., Zhang, H. (2022). Research on Modeling and Application of Milling Process Information of Blisk Blade. In: Liu, H., et al. Intelligent Robotics and Applications. ICIRA 2022. Lecture Notes in Computer Science(), vol 13455. Springer, Cham. https://doi.org/10.1007/978-3-031-13844-7_29

Download citation

DOI: https://doi.org/10.1007/978-3-031-13844-7_29

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-13843-0

Online ISBN: 978-3-031-13844-7

eBook Packages: Computer ScienceComputer Science (R0)