Abstract

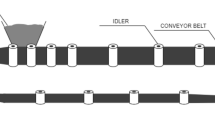

This paper presents a case study in indirect mass flow estimation of bulk material on conveyor belts, based on measuring the electric net energy demand of the drive motor. The aim is to replace traditional expensive measurement hardware, which results in benefits such as lowering overall costs as well as the possibility of working under harsh environmental conditions, such as dust, vibrations, weather, humidity, or temperature fluctuations. The data-driven model uses a dynamic estimation of the idle power in order to take into account time-varying influences. The case study has been developed in close collaboration between industry and scientific partners. Experiences gained from a first field prototype were used and incorporated to create an improved prototype setup, including a modular software infrastructure for automatically capturing all relevant measurement data. We discuss some of the challenges in development, like data quality, as well as our experiences in academia-industry collaboration. The presented case study showcases the importance to bring research into real-world applications for generating technology innovations.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Al-Thyabat, S., Miles, N., Koh, T.: Estimation of the size distribution of particles moving on a conveyor belt. Miner. Eng. 20(1), 72–83 (2007)

Deng, F., Liu, J., Deng, J., Fung, K.S., Lam, E.Y.: A three-dimensional imaging system for surface profilometry of moving objects. In: 2013 IEEE International Conference on Imaging Systems and Techniques (IST), pp. 343–347. IEEE (2013)

Djokorayono, R., Arfittariah, Priantama, D.B., Biyanto, T.R.: Design of belt conveyor weight scale using gamma radiation technique. In: AIP Conference Proceedings, vol. 2088, p. 020048. AIP Publishing LLC (2019)

Gebler, O.F., Hicks, B., Yon, J., Barker, M.: Characterising conveyor belt system usage from drive motor power consumption and rotational speed: a feasibility study. In: European Conference of the Prognostics and Health Management Society (PHM Society)

Guyot, O., Monredon, T., LaRosa, D., Broussaud, A.: Visiorock, an integrated vision technology for advanced control of comminution circuits. Miner. Eng. 17(11–12), 1227–1235 (2004)

Heinzl, B., Martinez-Gil, J., Himmelbauer, J., Roßbory, M., Hinterdorfer, C., Hinterreiter, C.: Indirect mass flow estimation based on power measurements of conveyor belts in mineral processing applications. In: Proceedings of the 19th International Conference on Industrial Informatics (INDIN), pp. 1–6 (2021). https://doi.org/10.1109/INDIN45523.2021.9557482

Hulthén, E.: Real-Time Optimization of Cone Crushers. Chalmers Tekniska Hogskola, Sweden (2010)

Itävuo, P., Hulthén, E., Yahyaei, M., Vilkko, M.: Mass balance control of crushing circuits, vol. 135, pp. 37–47. https://doi.org/10.1016/j.mineng.2019.02.033

Jeinsch, T., Sader, M., Ding, S., Engel, P., Jahn, W., Niemz, R.: A model-based information system for simulation and monitoring of belt conveyor systems. IFAC Proc. Volumes 33(26), 637–642 (2000)

Kaartinen, J.: Machine Vision in Measurement and Control of Mineral Concentration Process. http://lib.tkk.fi/Diss/2009/isbn9789512299553/

Mkwelo, S.: A machine vision-based approach to measuring the size distribution of rocks on a conveyor belt. Ph.D. thesis, University of Cape Town (2004)

Rehman, T., Tahir, W., Lim, W.: Kalman filtering for precise mass flow estimation on a conveyor belt weigh system. In: Zhang, D., Wei, B. (eds.) Mechatronics and Robotics Engineering for Advanced and Intelligent Manufacturing. LNME, pp. 329–338. Springer, Cham (2017). https://doi.org/10.1007/978-3-319-33581-0_25

Taskinen, A., Vilkko, M., Itävuo, P., Jaatinen, A.: Fast size distribution estimation of crushed rock aggregate using laserprofilometry. IFAC Proc. Volumes 44(1), 12132–12137 (2011)

Väyrynen, T., Itävuo, P., Vilkko, M., Jaatinen, A., Peltonen, M.: Mass-Flow Estimation in Mineral-Processing Applicationsm vol. 46(16), pp. 271–276. https://doi.org/10.3182/20130825-4-US-2038.00023,www.sciencedirect.com/science/article/pii/S1474667016313210

Yamazaki, T., Sakurai, Y., Ohnishi, H., Kobayashi, M., Kurosu, S.: Continuous mass measurement in checkweighers and conveyor belt scales. In: Proceedings of the 41st SICE Annual Conference. SICE 2002, vol. 1, pp. 470–474. IEEE (2002)

Zhao, L.: Typical failure analysis and processing of belt conveyor. Proc. Eng. 26, 942–946 (2011)

Acknowledgements

The research presented in this paper has been funded by the Austrian Federal Ministry for Climate Action, Environment, Energy, Mobility, Innovation and Technology (BMK), the Federal Ministry for Digital and Economic Affairs (BMDW), and the Province of Upper Austria in the frame of the COMET Competence Centers for Excellent Technologies Programme and the COMET Module S3AI managed by the Austrian Research Promotion Agency FFG.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Heinzl, B., Hinterreiter, C., Roßbory, M., Hinterdorfer, C. (2022). Challenges in Mass Flow Estimation on Conveyor Belts in the Mining Industry: A Case Study. In: Kotsis, G., et al. Database and Expert Systems Applications - DEXA 2022 Workshops. DEXA 2022. Communications in Computer and Information Science, vol 1633. Springer, Cham. https://doi.org/10.1007/978-3-031-14343-4_9

Download citation

DOI: https://doi.org/10.1007/978-3-031-14343-4_9

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-14342-7

Online ISBN: 978-3-031-14343-4

eBook Packages: Computer ScienceComputer Science (R0)