Abstract

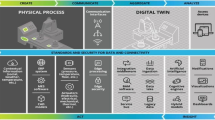

Cyber-physical manufacturing systems with industry 4.0 technologies have the ability to generate real-time data on the behavior of the system in each of its components, so predictions can be generated from this data. This article presents a method for the development of a predictive model where process mining techniques and data mining algorithms are combined. Through the discovery techniques of process mining, a descriptive analysis of the system is carried out to subsequently develop a predictive model with predictive data mining algorithms that provide information on the time remaining for a product that is in process to be completed. This prediction allows decision makers to reconfigure the manufacturing system variables and its schedule to optimize its performance. The method was applied in a production system that is currently installed in the Computer Integration Manufacturing Lab at Pontificia Universidad Javeriana.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Aalst, W.V.D.: Process Mining - Data Science in Action. Springer, Heidelberg (2016). https://doi.org/10.1007/978-3-662-49851-4

Aalst, W.V.D., Schonenberg, M.H., Song, M.: Time prediction based on process mining. Inf. Syst. 36(2), 450–475 (2011)

van der Aalst, W., et al.: Process mining manifesto. In: Daniel, F., Barkaoui, K., Dustdar, S. (eds.) BPM 2011. LNBIP, vol. 99, pp. 169–194. Springer, Heidelberg (2012). https://doi.org/10.1007/978-3-642-28108-2_19

Choueiri, A.C., Sato, D.M.V., Scalabrin, E.E., Santos, E.A.P.: An extended model for remaining time prediction in manufacturing systems using process mining. J. Manuf. Syst. 56, 188–201 (2020)

Dreher, S., Reimann, P., Gröger, C.: Application fields and research gaps of process mining in manufacturing companies. INFORMATIK 2020 (2021)

Hermann, M., Pentek, T., Otto, B.: Design principles for industries 4.0 scenarios. In: 2016 49th Hawaii international conference on system sciences (HICSS), pp. 3928–3937. IEEE (2016)

IBM: CRISP-DM help overview (2020). https://www.ibm.com/docs/en/spssmodeler/SaaS?topic=dm-crisp-help-overview. Accessed 2 May 2022

Jimenez, J.F., Zambrano-Rey, G., Aguirre, S., Trentesaux, D.: Using process mining for understating the emergence of self-organizing manufacturing systems. IFAC-PapersOnLine 51(11), 1618–1623 (2018)

Lee, E.A.: Cyber physical systems: design challenges. In: 2008 11th IEEE International Symposium on Object and Component-Oriented Real-Time Distributed Computing (ISORC), pp. 363–369. IEEE (2008)

Lee, J., Bagheri, B., Kao, H.A.: A cyber-physical systems architecture for industry 4.0-based manufacturing systems. Manuf. Lett. 3, 18–23 (2015)

López Castro, L., Martínez, S., Rodriguez, N., Lovera, L., Santiago Aguirre, H., Jimenez, J.-F.: Development of a predictive process monitoring methodology in a self-organized manufacturing system. In: Trentesaux, D., Borangiu, T., Leitão, P., Jimenez, J.-F., Montoya-Torres, J.R. (eds.) SOHOMA 2021. SCI, vol. 987, pp. 3–16. Springer, Cham (2021). https://doi.org/10.1007/978-3-030-80906-5_1

Lorenz, R., Senoner, J., Sihn, W., Netland, T.: Using process mining to improve productivity in make-to-stock manufacturing. Int. J. Prod. Res. 59(16), 4869–4880 (2021)

Lozano, C.V., Vijayan, K.K.: Literature review on cyber physical systems design. Procedia Manuf. 45, 295–300 (2020)

Nirdizati Org.: Why Nirdizati? (2020). http://nirdizati.org/why-nirdizati/. Accessed 30 April 2022

Schuh, G., Gützlaff, A., Schmitz, S., van der Aalst, W.M.: Data-based description of process performance in end-to-end order processing. CIRP Ann. 69(1), 381–384 (2020)

Shmueli, G., Bruce, P.C., Yahav, I., Patel, N.R., Lichtendahl, K.C. Jr.: Data Mining for Business Analytics: Concepts, Techniques, and Applications in R. Wiley (2017)

Teinemaa, I., Dumas, M., Rosa, M.L., Maggi, F.M.: Outcome-oriented predictive process monitoring: review and benchmark. ACM Trans. Knowl. Discovery Data (TKDD) 13(2), 1–57 (2019)

Van Dongen, B., van Luin, J., Verbeek, E.: Process mining in a multi-agent auctioning system. In: Proceedings of the 4th International Workshop on Modelling of Objects, Components, and Agents, Turku, pp. 145–160 (2006)

Veit, F., Geyer-Klingeberg, J., Madrzak, J., Haug, M., Thomson, J.: The proactive insights engine: process mining meets machine learning and artificial intelligence. In: BPM (Demos) (2017)

Yilmaz, S.E.: Overcoming the technology myopia of industry 4.0 (2020). https://eds-b-ebscohostcom.ezproxy.javeriana.edu.co/eds/pdfviewer/pdfviewervid=5&sid=9b9034fdd93c-405b-866c-a1fe06e1d94a%40sessionmgr101. Accessed 30 April 2022

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Aguirre, S., Zuñiga, L., Arias, M. (2022). Predictive Method Proposal for a Manufacturing System with Industry 4.0 Technologies. In: Figueroa-García, J.C., Franco, C., Díaz-Gutierrez, Y., Hernández-Pérez, G. (eds) Applied Computer Sciences in Engineering. WEA 2022. Communications in Computer and Information Science, vol 1685. Springer, Cham. https://doi.org/10.1007/978-3-031-20611-5_10

Download citation

DOI: https://doi.org/10.1007/978-3-031-20611-5_10

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-20610-8

Online ISBN: 978-3-031-20611-5

eBook Packages: Computer ScienceComputer Science (R0)