Abstract

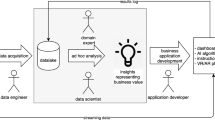

Plastic injection moulding requires careful management of machine parameters to achieve consistently high product quality. To avoid quality issues and minimize productivity losses, initial setup as well as continuous adjustment of these parameters during production are critical. Stakeholders involved in the parameterization rely on experience, extensive documentation in guidelines and Failure Mode and Effects Analysis (FMEA) documents, as well as a wealth of sensor data to inform their decisions. This disparate, heterogeneous, and largely unstructured collection of information sources is difficult to manage across systems and stakeholders, and results in tedious processes. This limits the potential for knowledge transfer, reuse, and automated learning. To address this challenge, we introduce a knowledge graph that supports injection technicians in complex setup and adjustment tasks. We motivate and validate our approach with a machine parameter recommendation use case provided by a leading supplier in the automotive industry. To support this use case, we created ontologies for the representation of parameter adjustment protocols and FMEAs, and developed extraction components using these ontologies to populate the knowledge graph from documents. The artifacts created are part of a process-aware information system that will be deployed within a European project at multiple use case partners. Our ontologies are available at https://short.wu.ac.at/FMEA-AP, and the software at https://short.wu.ac.at/KGSWC2022.

This research has received funding from the Teaming.AI project, which is part of the European Union’s Horizon 2020 research and innovation program under grant agreement No. 957402.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Bachhofner, S., Kiesling, E., Kabul, K., Sallinger, E., Waibel, P.: Knowledge graph modularization for cyber-physical production systems. In: International Semantic Web Conference (Poster), Virtual Conference, October 2021

Bellomarini, L., Fakhoury, D., Gottlob, G., Sallinger, E.: Knowledge graphs and enterprise AI: the promise of an enabling technology. In: 2019 IEEE 35th International Conference on Data Engineering (ICDE), Macau SAR, China, pp. 26–37. IEEE, April 2019

Bellomarini, L., Sallinger, E., Vahdati, S.: Knowledge graphs: the layered perspective. In: Janev, V., Graux, D., Jabeen, H., Sallinger, E. (eds.) Knowledge Graphs and Big Data Processing. LNCS, vol. 12072, pp. 20–34. Springer, Cham (2020). https://doi.org/10.1007/978-3-030-53199-7_2

Bozdana, A., Eyercioglu, Ö.: Development of an expert system for the determination of injection moulding parameters of thermoplastic materials: EX-PIMM. J. Mater. Process. Technol. 128(1), 113–122 (2002)

Buchgeher, G., Gabauer, D., Martinez-Gil, J., Ehrlinger, L.: Knowledge graphs in manufacturing and production: a systematic literature review. IEEE Access 9, 55537–55554 (2021)

Dittmann, L., Rademacher, T., Zelewski, S.: Performing FMEA using ontologies. In: 18th International Workshop on Qualitative Reasoning, Evanston, IL, USA, pp. 209–216, August 2004

Ebrahimipour, V., Rezaie, K., Shokravi, S.: An ontology approach to support FMEA studies. Expert Syst. Appl. 37(1), 671–677 (2010)

Hodkiewicz, M., Klüwer, J.W., Woods, C., Smoker, T., Low, E.: An ontology for reasoning over engineering textual data stored in FMEA spreadsheet tables. Comput. Ind. 131, 103496 (2021)

Hubauer, T., Lamparter, S., Haase, P., Herzig, D.M.: Use cases of the industrial knowledge graph at siemens. In: International Semantic Web Conference (P &D/Industry/BlueSky), Monterey, CA, USA, October 2018

ISO Central Secretary: Quality management systems - particular requirements for the application of ISO 9001:2000 for automotive production and relevant service part organizations. Standard ISO/TS 16949:2009 (2009)

Johnson, M., Vera, A.: No AI is an island: the case for teaming intelligence. AI Mag. 40(1), 16–28 (2019)

Kagermann, H., Wahlster, W., Helbig, J., et al.: Recommendations for implementing the strategic initiative Industrie 4.0: final report of the Industrie 4.0 working group. Technical report, Berlin, Germany (2013)

Klingenberg, C.O., Borges, M.A.V., Antunes, J.A.V., Jr.: Industry 4.0 as a data-driven paradigm: a systematic literature review on technologies. J. Manuf. Technol. Manag. (2019)

Koji, Y., Kitamura, Y., Mizoguchi, R., et al.: Ontology-based transformation from an extended functional model to FMEA. In: 15th International Conference on Engineering Design, pp. 323–324. Melbourne, Australia, August 2005

Kronos Incorporated: Overall Labor Effectiveness (OLE): Achieving a highly effective workforce (2007). https://workforceinstitute.org/wp-content/uploads/2008/01/ole-achieving-highly-effective-workforce.pdf. Accessed: 02 June 2022

Lee, B.H.: Using FMEA models and ontologies to build diagnostic models. AI EDAM 15(4), 281–293 (2001)

Molhanec, M., Zhuravskaya, O., Povolotskaya, E., Tarba, L.: The ontology based FMEA of lead free soldering process. In: 34th International Spring Seminar on Electronics Technology (ISSE), Tratanska, Lomnica, Slovakia, pp. 267–273. IEEE, May 2011

Noy, N.F., McGuinness, D.L., et al.: Ontology development 101: a guide to creating your first ontology (2001)

OMG: Business Process Model and Notation (BPMN), Version 2.0.2, December 2013. http://www.omg.org/spec/BPMN/2.0.2

Rehman, Z., Kifor, C.V.: An ontology to support semantic management of FMEA knowledge. Int. J. Comput. Commun. Control 11(4), 507–521 (2016)

Russomanno, D.J., Bonnell, R.D., Bowles, J.B.: Functional reasoning in a failure modes and effects analysis (FMEA) expert system. In: Annual Reliability and Maintainability Symposium 1993 Proceedings, Atlanta, GA, USA, pp. 339–347. IEEE, January 1993

Salas, E., Sims, D.E., Burke, C.S.: Is there a “big five’’ in teamwork? Small Group Res. 36(5), 555–599 (2005)

Stamatis, D.H.: Failure Mode and Effect Analysis: FMEA from Theory to Execution. Quality Press, Milwaukee (2003)

Wu, Z., Liu, W., Nie, W.: Literature review and prospect of the development and application of FMEA in manufacturing industry. Int. J. Adv. Manuf. Technol. 112(5–6), 1409–1436 (2021)

Xiuxu, Z., Yuming, Z.: Application research of ontology-enabled process FMEA knowledge management method. Int. J. Intell. Syst. Appl. 34–40 (2012)

Zhao, X., Zhu, Y.: Research of FMEA knowledge sharing method based on ontology and the application in manufacturing process. In: 2nd International Workshop on Database Technology and Applications, Wuhan, China, pp. 1–4. IEEE, November 2010

Zhou, B., Svetashova, Y., Pychynski, T., Kharlamov, E.: Semantic ML for manufacturing monitoring at Bosch. In: International Semantic Web Conference (Demos/Industry), Virtual Conference, November 2020

Acknowledgements

This work received funding from the Teaming.AI project in the European Union’s Horizon 2020 research and innovation program under grant agreement No. 95740.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Bachhofner, S., Kurniawan, K., Kiesling, E., Revoredo, K., Bayomie, D. (2022). Knowledge Graph Supported Machine Parameterization for the Injection Moulding Industry. In: Villazón-Terrazas, B., Ortiz-Rodriguez, F., Tiwari, S., Sicilia, MA., Martín-Moncunill, D. (eds) Knowledge Graphs and Semantic Web . KGSWC 2022. Communications in Computer and Information Science, vol 1686. Springer, Cham. https://doi.org/10.1007/978-3-031-21422-6_8

Download citation

DOI: https://doi.org/10.1007/978-3-031-21422-6_8

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-21421-9

Online ISBN: 978-3-031-21422-6

eBook Packages: Computer ScienceComputer Science (R0)