Abstract

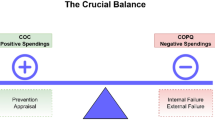

The cost of quality while a well-established measure in the manufacturing and other industries, has shown to have limited data available within the construction industry. This case study research article seeks to establish within the construction industry the cost of quality throughout the project lifecycle. The Lean Six Sigma methodology of Design, Measure, Analyse, Improve and Control was used to develop a framework to raise awareness and track the cost of quality both good and bad. The Prevention Appraisal Failure model was used to determine the cost of quality across a portfolio of construction projects completed. The research found that cost of failure was in excess of the cost of appraisal and prevention and thus was leading to non- value add effects waste. During the internal audit process a lack of adherence to documented processes within the quality system was identified as directly contributing to the cost of poor quality in a number of projects. An improvement in the tracking of costs was delivered due to the implementation of a structured framework for data capture and a training presentation to raise awareness. The framework is to be a robust structure and framework that could be adapted in other construction companies and possibly other industries.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Mahmood, S., Ahmed, S.M., Panthi, K., Ishaque Kureshi, N.: Determining the cost of poor quality and its impact on productivity and profitability. Built Environ. Proj. Asset Manag. 4, 296–311 (2014). https://doi.org/10.1108/BEPAM-09-2013

Zimon, D., Zimon, G.: The impact of implementation of standardized quality management systems on management of liabilities in group purchasing organizations. Qual. Innov. Prosperity 23, 60–73 (2019)

Construction Network Ireland: Ireland Construction Market Size, Trends and Forecasts by Sector - 2022–2026. Construction Network Ireland, Dublin (2022)

Abdelsalam, H.M.E., Gad, M.M.: Cost of quality in Dubai: an analytical case study of residential construction projects. Int. J. Project Manage. 27, 501–511 (2009). https://doi.org/10.1016/j.ijproman.2008.07.006

Heravi, G., Jafari, A.: Cost of quality evaluation in mass-housing projects in developing countries. J. Constr. Eng. Manage.-asce. 140, 04014004 (2014)

Garg, S., Misra, S.: Understanding the components and magnitude of the cost of quality in building construction. Eng. Constr. Archit. Manag. 29, 26–48 (2022). https://doi.org/10.1108/ECAM-08-2020-0642

Hoonakker, P.L.T., Carayon, P., Loushine, T.W.: Barriers and benefits of quality management in the construction industry: an empirical study. Total Qual. Manag. Bus. Excell. 21, 953–969 (2010)

Rosenfeld, Y.: Cost of quality versus cost of non-quality in construction: the crucial balance. Constr. Manag. Econ. 27, 107–117 (2009). https://doi.org/10.1080/01446190802651744

Hall, M., Tomkins, C.: A cost of quality analysis of a building project: towards a complete methodology for design and build. Constr. Manag. Econ. 19, 727–740 (2001). https://doi.org/10.1080/01446190110066146

Love, P.E.D., Li, H.: Quantifying the causes and costs of rework in construction. Constr. Manag. Econ. 18, 479–490 (2000). https://doi.org/10.1080/01446190050024897

Lyons, T.: How resilience and values helped Kirby create a €300 m business (2021). https://www.kirbygroup.com/how-resilience-and-values-helped-kirby-create-a-e300m-business-mark-flanagan-speaks-to-the-currency/

Vaxevanidis, N.M., Petropoulos, G., Avakumovic, J., Mourlas, A.: Cost of quality models and their implementation in manufacturing firms. Int. J. Qual. Res. 3, 27–36 (2009)

Bisgaard, S.: Quality management and Juran’s legacy. Qual. Reliab. Eng. Int. 23, 665–677 (2007). https://doi.org/10.1002/qre.860

Juran, J.M., Godfrey, A.B., Hoogstoel, R.E., Schilling, E.G.: The Quality Improvement Process. Juran’s Quality Handbook. McGraw-Hill, New York (1999)

Escobar, C.A., Morales-Menendez, R.: Machine learning techniques for quality control in high conformance manufacturing environment. Adv. Mech. Eng. 10, 1687814018755519 (2018)

Haupt, T.C., Whiteman, D.E.: Inhibiting factors of implementing total quality management on construction sites. TQM Mag. 16, 166–173 (2004). https://doi.org/10.1108/09544780410532891

Alwi, S., Hampson, K., Mohamed, S.: Non value-adding activities: a comparative study of Indonesian and Australian construction projects. Presented at the (2002)

Aziz, R.F., Hafez, S.M.: Applying lean thinking in construction and performance improvement. Alex. Eng. J. 52, 679–695 (2013)

McDermott, O., Nelson, S.: Readiness for Industry 4.0 in west of Ireland small and medium and micro enterprises. College of Science and Engineering, University of Galway (2022). https://doi.org/10.13025/8sqs-as24

Sauce, B., Matzel, L.D.: Inductive Reasoning. In: Vonk, J. and Shackelford, T. (eds.) Encyclopedia of Animal Cognition and Behavior, pp. 1–8. Springer International Publishing, Cham (2017). https://doi.org/10.1007/978-3-319-47829-6_1045-1

Robsen, C.: Real World Research: A Resource for Social Scientists and Practitioner- Researchers. Blackwell Publishers, Oxford (2002)

International Organisation for Standardisation: ISO 9001:2015. https://www.iso.org/obp/ui/#iso:std:iso:9001:ed-5:v1:en. Accessed 15 Feb 2021

Arnheiter, E.D., Maleyeff, J.: The integration of lean management and six sigma. TQM Mag. 17, 5–18 (2005). https://doi.org/10.1108/09544780510573020

de Mast, J., Lokkerbol, J.: An analysis of the six sigma DMAIC method from the perspective of problem solving. Int. J. Prod. Econ. 139, 604–614 (2012). https://doi.org/10.1016/j.ijpe.2012.05.035

ISO 19001:2018. https://www.iso.org/cms/render/live/en/sites/isoorg/contents/data/standard/07/00/70017.html. Accessed 17 Nov 2022

Xiao, H., Proverbs, D.: The performance of contractors in Japan, the UK and the USA: a comparative evaluation of construction cost. Constr. Manag. Econ. 20, 425–435 (2002). https://doi.org/10.1080/01446190210145859

Sebastian, B., Jan, G., Monika, P., Wojciech, S.: The most economically advantageous tender in the public procurement system in the European union. In: Bilgin, M.H., Danis, H., Karabulut, G., Gözgor, G. (eds.) Eurasian Economic Perspectives. ESBE, vol. 12/1, pp. 403–420. Springer, Cham (2020). https://doi.org/10.1007/978-3-030-35040-6_26

Rother, M., Shook, J.: Learning to See: Value Stream Mapping to Add Value and Eliminate Muda. Lean Enterprise Institute, Cambridge (2003)

Chiarini, A.: Japanese total quality control, TQM, deming’s system of profound knowledge, BPR, Lean and six sigma: comparison and discussion. Int. J. Lean Six Sigma. 2, 332–355 (2011). https://doi.org/10.1108/20401461111189425

Abdul-Aziz, A.: The realities of applying total quality management in the construction industry. Struct. Surv. 20, 88–96 (2002). https://doi.org/10.1108/02630800210433864

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 IFIP International Federation for Information Processing

About this paper

Cite this paper

O’Connor, C., McDermott, O. (2023). Cost of Quality in Construction. In: McDermott, O., Rosa, A., Sá, J.C., Toner, A. (eds) Lean, Green and Sustainability. ELEC 2022. IFIP Advances in Information and Communication Technology, vol 668. Springer, Cham. https://doi.org/10.1007/978-3-031-25741-4_26

Download citation

DOI: https://doi.org/10.1007/978-3-031-25741-4_26

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-25740-7

Online ISBN: 978-3-031-25741-4

eBook Packages: Computer ScienceComputer Science (R0)