Abstract

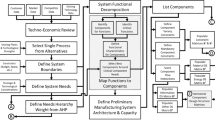

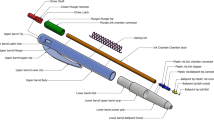

In the current developing world, Technical Systems are required to satisfy variable customers’ needs. This means they should be designed to facilitate multifunctionality with a simultaneous reduction in resource usage consumed for products with many components having minimal functionality index. The proposed approach is to develop a method for components clustering on a functional level to identify functional modules being sets of components that perform a main function on a target component. Such clustering is quantified as a novel modularity index derived from the value equation used in TRIZ and coupled with existing modularity metrics. As a result of the work, a clustering mechanism for Technical System Components was proposed that facilitates the design of modular, multi-variant products. Additionally, the proposed method can help to assess the design from the point of view of its modular structure, indicating areas for further development, including Trimming and Contradiction Defining approaches. The proposed method can reduce the time and costs associated with a modular design. Additionally, designed Technical Systems can be more prone to modifications. In total, this approach can improve the adaptivity of a Technical System, reducing manufacturing costs.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Mysior, M.: Modular Ideality for Systematic Segmentation. In: Nowak, R., Chrząszcz, J., and Brad, S. (eds.) Systematic Innovation Partnerships with Artificial Intelligence and Information Technology. TFC 2022. IFIP Advances in Information and Communication Technology, vol. 655, pp. 145–153. Springer, Cham (2022). https://doi.org/10.1007/978-3-031-17288-5_13

Altshuller, G.: And Suddenly the Inventor Appeared: TRIZ, the Theory of Inventive Problem Solving. Technical Innovation Center Inc, Worcester, Mass (1996)

Altshuller, G.: Creativity as an Exact Science: the Theory of the Solution of Inventive Problems. Gordon and Breach Science Publishers, New York (1984)

Lyubomirskiy, A., Litvin, S., Ikovenko, S., Thurnes, C.M., Adunka, R.: Trends of Engineering System Evolution (TESE): TRIZ paths to innovation. TRIZ Consulting Group, Sulzbach-Rosenberg (2018)

Ghane, M., Ang, M.C., Cavallucci, D., Kadir, R.A., Ng, K.W., Sorooshian, S.: TRIZ trend of engineering system evolution: a review on applications, benefits, challenges and enhancement with computer-aided aspects. Comput. Ind. Eng. 174, 108833 (2022). https://doi.org/10.1016/j.cie.2022.108833

Cascini, G., Rotini, F., Russo, D.: Functional modeling for TRIZ-based evolutionary analyses. In: Presented at the International Conference on Engineering Design , Stanford University, Stanford, CA, USA (2009)

Makino, K., Sawaguchi, M., Miyata, N.: Research on functional analysis useful for utilizing TRIZ. Procedia Eng. 131, 1021–1030 (2015). https://doi.org/10.1016/j.proeng.2015.12.420

Mayer, O.: Flexible lighting distribution on party ships. Zeszyty Naukowe Akademii Morskiej w Szczecinie, 49(121), 9–16 (2017). https://doi.org/10.17402/195

Dong, Y..-F., Zhang, P., Tan, R.-H., Liu, W., Wang, R.-Q., Sun, J.-G.: Study on establishing functional periodicity of new products based on TRIZ. In: Cavallucci, D., De Guio, R., Koziołek, S. (eds.) TFC 2018. IAICT, vol. 541, pp. 113–125. Springer, Cham (2018). https://doi.org/10.1007/978-3-030-02456-7_10

Schulz, A.P., Clausing, D.P., Fricke, E., Negele, H.: Development and integration of winning technologies as key to competitive advantage. Syst. Eng. 3, 180–211 (2000). https://doi.org/10.1002/1520-6858(2000)3:4%3c180::AID-SYS2%3e3.0.CO;2-H

Abramov, O.: Triz-Based cause and effect chains analysis vs root cause analysis. In: Presented at the TRIZ-Fest , Seoul, Korea (2015)

Li, M., Ming, X., He, L., Zheng, M., Xu, Z.: A TRIZ-based trimming method for patent design around. Comput. Aided Des. 62, 20–30 (2015). https://doi.org/10.1016/j.cad.2014.10.005

Sheu, D.D., Hou, C.T.: TRIZ-based systematic device trimming: theory and application. Procedia Eng. 131, 237–258 (2015). https://doi.org/10.1016/j.proeng.2015.12.385

Sheu, D.D., Hou, C.T.: TRIZ-based trimming for process-machine improvements: slit-valve innovative redesign. Comput. Ind. Eng. 66, 555–566 (2013). https://doi.org/10.1016/j.cie.2013.02.006

Chrząszcz, J., Bertoncelli, T., Gronauer, B., Oliver Mayer, Nähler, H.: Modeling IT systems in TRIZ. In: Nowak, R., Chrząszcz, J., and Brad, S. (eds.) Systematic Innovation Partnerships with Artificial Intelligence and Information Technology. TFC 2022. IFIP Advances in Information and Communication Technology, vol. 655, pp. 248–260. Springer, Cham (2022). https://doi.org/10.1007/978-3-031-17288-5_22

Mattson, C.A., Magleby, S.P.: the influence of product modularity during concept selection of consumer products. In: Volume 4: 13th International Conference on Design Theory and Methodology, pp. 299–308. American Society of Mechanical Engineers, Pittsburgh, Pennsylvania, USA (2001). https://doi.org/10.1115/DETC2001/DTM-21712

Ulrich, K.T., Eppinger, S.D.: Product Design and Development, 5th edn. McGraw-Hill Education, New York (2011)

Gershenson, J.K., Prasad, G.J., Zhang, Y.: Product modularity: measures and design methods. J. Eng. Des. 15, 33–51 (2004). https://doi.org/10.1080/0954482032000101731

Gershenson, J.K., Prasad, G.J., Zhang, Y.: Product modularity: definitions and benefits. J. Eng. Des. 14, 295–313 (2003). https://doi.org/10.1080/0954482031000091068

Newcomb, Rosen, Bras: Life cycle modularity metrics for product design. In: 2003 EcoDesign 3rd International Symposium on Environmentally Conscious Design and Inverse Manufacturing, pp. 251–258. IEEE, Tokyo, Japan (2003). https://doi.org/10.1109/ECODIM.2003.1322671

Gao, F., Xiao, G., Simpson, T.W.: Identifying functional modules using generalized directed graphs: definition and application. Comput. Ind. 61, 260–269 (2010). https://doi.org/10.1016/j.compind.2009.09.007

Fiorineschi, L., Rotini, F.: Linking design problems and modular solutions. Int. J. Prod. Dev. 23, 15 (2019). https://doi.org/10.1504/IJPD.2019.098396

Li, Z., Wang, S., Yin, W.: Determining optimal granularity level of modular product with hierarchical clustering and modularity assessment. J. Braz. Soc. Mech. Sci. Eng. 41, 342 (2019). https://doi.org/10.1007/s40430-019-1848-y

Koziołek, S.: Design for change: disaggregation of functions in system architecture by TRIZ-based design. In: Chechurin, L., Collan, M. (eds.) Advances in Systematic Creativity, pp. 17–26. Springer, Cham (2019). https://doi.org/10.1007/978-3-319-78075-7_2

Hölttä-Otto, K., Chiriac, N.A., Lysy, D., Suk Suh, E.: Comparative analysis of coupling modularity metrics. J. Eng. Des. 23, 790–806 (2012). https://doi.org/10.1080/09544828.2012.701728

Morrison, J.R., Azhar, M., Lee, T., Suh, H.: Axiomatic design for eco-design: eAD+. J. Eng. Des. 24, 711–737 (2013). https://doi.org/10.1080/09544828.2013.822150

Erikstad, S. O.: Design for modularity. In: Papanikolaou, A. (ed.) A Holistic Approach to Ship Design, pp. 329–356. Springer, Cham (2019). https://doi.org/10.1007/978-3-030-02810-7_10

Erixon, G.: Design for modularity. In: Huang, G.Q. (ed.) Design for X, pp. 356–379. Springer, Dordrecht (1996). https://doi.org/10.1007/978-94-011-3985-4_18

Hölttä-Otto, K.: Modular Product Platform Design (2005)

Acknowledgements

The presented method was developed as part of a research task “Forecasting development of sandwich panels in modular technical systems” financed by a pro-quality subsidy for the development of the research potential of the Faculty of Mechanical Engineering of the Wroclaw University of Science and Technology in 2022. The case study was prepared based on the results of the project “Flexible production system (ESPP) of modular car trailers with GW up to 3500kg manufactured in HoneyTech technology”, project no.: POIR.01.01.01–00-0589/19, realized within Measure 1.1 „R&D projects of enterprises”, Sub-measure 1.1.1 „Industrial research and development work implemented by enterprises”, Project co-financed by the European Union from the European Regional Development Fund under the Smart Growth Operational Programme 2014–2020.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 IFIP International Federation for Information Processing

About this paper

Cite this paper

Mysior, M., Koziołek, S. (2023). Use of Function Analysis in the Design of Multi-Functional Products. In: Cavallucci, D., Livotov, P., Brad, S. (eds) Towards AI-Aided Invention and Innovation. TFC 2023. IFIP Advances in Information and Communication Technology, vol 682. Springer, Cham. https://doi.org/10.1007/978-3-031-42532-5_25

Download citation

DOI: https://doi.org/10.1007/978-3-031-42532-5_25

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-42531-8

Online ISBN: 978-3-031-42532-5

eBook Packages: Computer ScienceComputer Science (R0)