Abstract

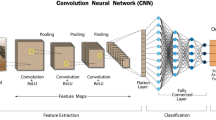

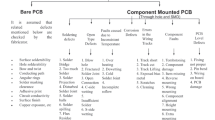

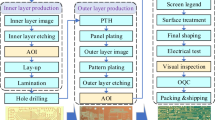

Today, the process of producing a printed circuit board assembly (PCBA) is growing rapidly, and this process requires cutting-edge debugging and testing of the boards. The Automatic Optical Inspection (AOI) process detects defects in the boards, components, or solder pads using image processing and machine learning (ML) algorithms. Although state-of-the-art approaches for identifying defects are well developed, due to three main issues, the ML algorithms and datasets are incapable of fully integrating into industrial plants. These issues are privacy limitations for sharing data, the distribution shifts in the PCBA industry, and the absence of a degree of freedom for reproducible and modifiable synthetic datasets.

This paper addresses these challenges and introduces “ReProInspect”, a comprehensive framework designed to meet these requirements. ReProInspect uses fabrication files from the designed PCBs in the manufacturing line to automatically generate 3D models of the PCBAs. By incorporating various techniques, the framework introduces controlled defects into the PCBA, thereby creating reproducible and differentiable defect datasets. The quality data produced by this framework enables an improved detection and classification scenario for AOI in industrial applications. The initial results of ReProInspect are demonstrated and discussed through detailed instances. Finally, the paper also highlights future work to improve the current state of the framework.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

Notes

- 1.

MarketWatch, The Prospects of Printed Circuit Board (PCB) Market 2023: Industry Trends and Challenges till 2030.

- 2.

Available (last seen on 18.08.2023): http://defectsdatabase.npl.co.uk/.

- 3.

Available: https://www.kicad.org/.

- 4.

Available (last seen on 18.08.2023):https://github.com/dmitrystu/Nucleo2USB.

References

Chen, M.C., et al.: A PCBA solder joint defects inspection system based on deep learning technology. In: 2023 IEEE International Conference on Consumer Electronics (ICCE), pp. 1–3. IEEE (2023)

Du, B., Wan, F., Lei, G., Xu, L., Xu, C., Xiong, Y.: YOLO-MBBi: PCB surface defect detection method based on enhanced YOLOv5. Electronics 12(13), 2821 (2023)

Du, Y., et al.: An automated optical inspection (AOI) platform for three-dimensional (3D) defects detection on glass micro-optical components (GMOC). Opt. Commun. 545, 129736 (2023)

Fridman, Y., Rusanovsky, M., Oren, G.: ChangeChip: a reference-based unsupervised change detection for PCB defect detection. In: 2021 IEEE Physical Assurance and Inspection of Electronics (PAINE), pp. 1–8. IEEE (2021)

Gamma, E., Helm, R., Johnson, R., Vlissides, J.: Design Patterns: Elements of Reusable Object-oriented Software. Pearson Education (1994)

Huang, W., Wei, P.: A PCB dataset for defects detection and classification. arXiv preprint arXiv:1901.08204 (2019)

Jessurun, N., et al.: FPIC: a novel semantic dataset for optical PCB assurance. ACM J. Emerg. Technol. Comput. Syst. 19(2), 1–21 (2023)

Kim, Y.G., Park, T.H.: SMT assembly inspection using dual-stream convolutional networks and two solder regions. Appl. Sci. 10(13), 4598 (2020)

Lavrik, E., Panasenko, I., Schmidt, H.R.: Advanced methods for the optical quality assurance of silicon sensors. Nucl. Instrum. Methods Phys. Res., Sect. A 922, 336–344 (2019)

Li, J., Gu, J., Huang, Z., Wen, J.: Application research of improved YOLO V3 algorithm in PCB electronic component detection. Appl. Sci. 9(18), 3750 (2019)

Li, Y.T., Kuo, P., Guo, J.I.: Automatic industry PCB board dip process defect detection system based on deep ensemble self-adaption method. IEEE Trans. Compon. Packag. Manuf. Technol. 11(2), 312–323 (2020)

Liao, X., Lv, S., Li, D., Luo, Y., Zhu, Z., Jiang, C.: YOLOv4-MN3 for PCB surface defect detection. Appl. Sci. 11(24), 11701 (2021)

Lu, H., Mehta, D., Paradis, O., Asadizanjani, N., Tehranipoor, M., Woodard, D.L.: FICS-PCB: a multi-modal image dataset for automated printed circuit board visual inspection. Cryptology ePrint Archive (2020)

Nau, J., Richter, J., Streitferdt, D., Kirchhoff, M.: Simulating the printed circuit board assembly process for image generation. In: 2020 IEEE 44th Annual Computers, Software, and Applications Conference, pp. 245–254. IEEE (2020)

Pennekamp, J., et al.: Privacy-preserving production process parameter exchange. In: Annual Computer Security Applications Conference, pp. 510–525 (2020)

Richter, J., Nau, J., Kirchhoff, M., Streitferdt, D.: KOI: an architecture and framework for industrial and academic machine learning applications. In: MDIS 2020. CCIS, vol. 1341, pp. 113–128. Springer, Cham (2021). https://doi.org/10.1007/978-3-030-68527-0_8

Shi, W., Lu, Z., Wu, W., Liu, H.: Single-shot detector with enriched semantics for PCB tiny defect detection. J. Eng. 2020(13), 366–372 (2020)

Tang, S., He, F., Huang, X., Yang, J.: Online PCB defect detector on a new PCB defect dataset. arXiv preprint arXiv:1902.06197 (2019)

Taori, R., Dave, A., Shankar, V., Carlini, N., Recht, B., Schmidt, L.: Measuring robustness to natural distribution shifts in image classification. Adv. Neural. Inf. Process. Syst. 33, 18583–18599 (2020)

Ulger, F., Yuksel, S.E., Yilmaz, A., Gokcen, D.: Solder joint inspection on printed circuit boards: a survey and a dataset. IEEE Trans. Instrum. Meas. 72, 1–21 (2023)

Wu, H., Lei, R., Peng, Y.: PCBNet: a lightweight convolutional neural network for defect inspection in surface mount technology. IEEE Trans. Instrum. Meas. 71, 1–14 (2022)

Acknowledgments

Thüringer Aufbaubank (TAB, 2021 FE 9036) provided financial support for this study.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2024 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Rezaei, A., Nau, J., Streitferdt, D., Schambach, J., Vangelov, T. (2024). ReProInspect: Framework for Reproducible Defect Datasets for Improved AOI of PCBAs. In: Kofroň, J., Margaria, T., Seceleanu, C. (eds) Engineering of Computer-Based Systems. ECBS 2023. Lecture Notes in Computer Science, vol 14390. Springer, Cham. https://doi.org/10.1007/978-3-031-49252-5_16

Download citation

DOI: https://doi.org/10.1007/978-3-031-49252-5_16

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-49251-8

Online ISBN: 978-3-031-49252-5

eBook Packages: Computer ScienceComputer Science (R0)