Abstract

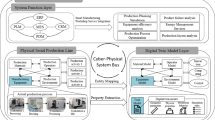

Commercial greenhouses require sophisticated energy management strategies to ensure optimal plant growth while minimizing operational costs. The ability to adapt energy usage flexibly in response to varying market prices and environmental conditions is crucial. This paper introduces a data-driven digital twin, incorporating discrete event simulations and symbolic regression, to model and optimize real-world processes within a commercial greenhouse. This approach enables precise control and adjustment of energy usage, enhancing flexibility. A case study of one of Denmark's largest commercial greenhouses is applied to demonstrate the digital twin's applicability and effectiveness. Implementation of the digital twin significantly enhanced the greenhouse's energy flexibility, allowing for adaptive energy consumption that aligns with fluctuating energy prices and availability without compromising plant growth. The results illustrate that digital twins can substantially improve energy flexibility, providing a valuable tool for greenhouse operators to optimize energy usage dynamically.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Howard, D.A., Ma, Z., Jørgensen, B.N.: Evaluation of industrial energy flexibility potential: a scoping review. In: 2021 22nd IEEE International Conference on Industrial Technology (ICIT) (2021)

Koulouris, A., Misailidis, N., Petrides, D.: Applications of process and digital twin models for production simulation and scheduling in the manufacturing of food ingredients and products. Food Bioprod. Process. 126, 317–333 (2021)

Tsubo, M., Walker, S.: Relationships between photosynthetically active radiation and clearness index at Bloemfontein, South Africa. Theoret. Appl. Climatol. 80(1), 17–25 (2004)

Choi, B.K., Kang, D., Modeling and Simulation of Discrete-Event Systems: Wiley. Hoboken (2013)

Qiao, D., Wang, Y.: A review of the application of discrete event simulation in manufacturing. In: IOP Conference Series: Earth and Environmental Science. IOP Publishing Ltd. (2021)

Yang, S.L., et al.: Verification of intelligent scheduling based on deep reinforcement learning for distributed workshops via discrete event simulation. Adv. Prod. Eng. Manage. 17(4), 401–412 (2022)

Aliunir, F., Zagloel, T.Y.M., Ardi, R.: Discrete-event simulation and optimization of spare parts inventory and preventive maintenance integration model considering cooling down and machine dismantling time factor. Evergreen 7(1), 79–85 (2020)

Rueda Delgado, R., et al.: A comparison between NARX neural networks and symbolic regression: an application for energy consumption forecasting. In: Medina, J., Ojeda-Aciego, M., Verdegay, J., Perfilieva, I., Bouchon-Meunier, B., Yager, R. (eds.) IPMU 2018. CCIS, vol. 855, pp. 16–27. Springer, Cham (2018). https://doi.org/10.1007/978-3-319-91479-4_2

Kabliman, E., et al.: Application of symbolic regression for constitutive modeling of plastic deformation. Appl. Eng. Sci. 6, 100052 (2021)

Mridula, M.R., Nair, A.S., Kumar, K.S.: Genetic programming based models in plant tissue culture: an addendum to traditional statistical approach. PLoS Comput. Biol. 14(2), e1005976 (2018)

Kantor, D., Zuben, F.J.V., Franca, F.O.d.: Simulated annealing for symbolic regression. In: Proceedings of the Genetic and Evolutionary Computation Conference, Lille, France, pp. 592–599. Association for Computing Machinery (2021)

Ashok, D., et al.: Logic Guided Genetic Algorithms (2020)

Angizeh, F., et al.: Optimal production scheduling for smart manufacturers with application to food production planning. Comput. Electr. Eng. 84, 106609 (2020)

Madoumier, M., et al.: Towards a holistic approach for multi-objective optimization of food processes: a critical review. Trends Food Sci. Technol. 86, 1–15 (2019)

Jafferali, M., Venkateshwaran, J., Son, Y.-J.: Performance comparison of search‐based simulation optimisation algorithms for operations scheduling. Int. J. Simul. Process Modell. 1, 58–71 (2005)

Eskandari, H., et al.: Performance analysis of commercial simulation-based optimization packages: OptQuest and wittness optimizer. In: Proceedings - Winter Simulation Conference, pp. 2358–2368 (2011)

McCree, K.J.: The action spectrum, absorptance and quantum yield of photosynthesis in crop plants. Agric. Meteorol. 9, 191–216 (1971)

Rhodes, B.: ephem (2022). https://pypi.org/project/ephem/. Accessed 26 July 2023

Qu, Y.: A Digital Twin Framework for Commercial Greenhouse Climate Control System, in Center for Energy Informatics, University of Southern Denmark: Syddansk Universitet. Det Tekniske Fakultet (2023)

Acknowledgments

The work is part of the Greenhouse Industry 4.0 project funded by the Energy Technology Development and Demonstration Program (64019-0018), and part of Project “IEA IETS Annex Task XVIII - Digitization, artificial intelligence and related technologies for energy efficiency and reduction of greenhouse gas emissions in industry” funded by EUDP (Case no.134-21010).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Ethics declarations

The authors have no competing interests to declare that are relevant to the content of this article.

Rights and permissions

Copyright information

© 2025 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Howard, D.A., Værbak, M., Ma, Z., Jørgensen, B.N., Ma, Z. (2025). Data-Driven Digital Twin Based Energy Flexibility Investigation for Commercial Greenhouse Production Process. In: Santos, M.F., Machado, J., Novais, P., Cortez, P., Moreira, P.M. (eds) Progress in Artificial Intelligence. EPIA 2024. Lecture Notes in Computer Science(), vol 14967. Springer, Cham. https://doi.org/10.1007/978-3-031-73497-7_16

Download citation

DOI: https://doi.org/10.1007/978-3-031-73497-7_16

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-73496-0

Online ISBN: 978-3-031-73497-7

eBook Packages: Computer ScienceComputer Science (R0)