Abstract

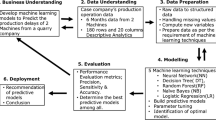

In the industrial context, thousands of data are generated every day, which, once processed, can be transformed into valuable information for the business and to support decision-making. This paper is applied to the case study of the textile industry - one of Portugal's oldest and most important industries, which has been reorganizing itself over the years to keep up with changes in the market. However, regarding data exploitation, decisions are primarily based on opinions and assumptions, not based on the daily data. This study aims to apply a set of data mining techniques to solve the classification problem in the textile industry: predicting, when planning production, whether an order will be delayed. In the study, 28 models were included. These models are designed based on business knowledge, considering variables that can influence the target. Overall, this study shows the potential of applying these models in an industrial context and using them to help plan orders. The best model developed has an accuracy of 94%, a sensitivity of 90%, a specificity of 98%, a precision of 97% and an F-Measure of 93%.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

de Medeiros, M.M., Hoppen, N., Maçada, A.C.G.: Data science for business: benefits, challenges and opportunities. Bottom Line 33(2), 149–163 (2020). https://doi.org/10.1108/BL-12-2019-0132

Provost, F., Fawcett, T.: Data science for business, p. 409 (2013)

Vicario, G., Coleman, S.: A review of data science in business and industry and a future view. Appl. Stoch. Models Bus. Ind. 36(1), 6–18 (2020). https://doi.org/10.1002/asmb.2488

Meter, H.: Revising the DIKW pyramid and the real relationship between data, information, knowledge and wisdom. Law Technol. Hum. 2, 69–80 (2020). https://doi.org/10.5204/lthj.1470

Zeferino, D.: Dados, Informação e Conhecimento: Qual a Diferença dos Conceitos?’ Certifiquei. https://www.certifiquei.com.br/dados-informacao-conhecimento/. Accessed 11 Feb 2023

Zaroni, H.W.P.: PROGRAMA DE PÓS-GRADUAÇÃO EM ENGENHARIA DE PRODUÇÃO, p. 93 (2019)

Direção-Geral das Atividades Económicas, ‘Sinopse Indústria Têxtil e Vestuário’ (2018)

Pérez Soto, D.M.C.: Caracterização ambiental do setor têxtil em Portugal (2018)

Aggarwal, C.C.: Data Mining: The Textbook. Springer, Cham (2015). https://doi.org/10.1007/978-3-319-14142-8

Lewandowski, S., Stańczyk, T.: Identification and classification of spliced wool combed yarn joints by artificial neural networks - Part I: developing an artificial neural network model. Fibres Text. East. Eur. 13, 39–43 (2005)

'Using an online platform for the improvement of industrial symbiosis and circular economy (in Western Macedonia, Greece)’. Glob. NEST J. 21(1), 76–81, January 2019. https://doi.org/10.30955/gnj.002735

Akyol, U., Tufekci, P., Kahveci, K., Cihan, A.: A model for predicting drying time period of wool yarn bobbins using computational intelligence techniques. Text. Res. J. 85, 1367–1380 (2015). https://doi.org/10.1177/0040517514553879

Seçkin, M., Seçkin, A.Ç., Coşkun, A.: Production fault simulation and forecasting from time series data with machine learning in glove textile industry. J. Eng. Fibers Fabr. 14, 155892501988346 (2019). https://doi.org/10.1177/1558925019883462

Yildirim, P., Birant, D., Alpyildiz, T.: Data mining and machine learning in textile industry. Wiley Interdisc. Rev.: Data Min. Knowl. Discovery 8(1), e1228 (2018). https://wires.onlinelibrary.wiley.com/doi/abs/10.1002/widm.1228

Acknowledgements

This work has been supported by FCT – Fundação para a Ciência e Tecnologia within the R&D Units Project Scope: UIDB/00319/2020.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2025 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Miranda, R., Portela, F. (2025). Data Mining Models to Predict Order with Delays: A Textile Case Study. In: Santos, M.F., Machado, J., Novais, P., Cortez, P., Moreira, P.M. (eds) Progress in Artificial Intelligence. EPIA 2024. Lecture Notes in Computer Science(), vol 14967. Springer, Cham. https://doi.org/10.1007/978-3-031-73497-7_30

Download citation

DOI: https://doi.org/10.1007/978-3-031-73497-7_30

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-73496-0

Online ISBN: 978-3-031-73497-7

eBook Packages: Computer ScienceComputer Science (R0)