Abstract

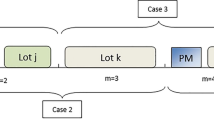

Given a short term mining plan, the task for an operational mine planner is to determine how the equipment in the mine should be used each day. That is, how crushers, loaders and trucks should be used to realise the short term plan. It is important to achieve both grade targets (by blending) and maximise the utilisation (i.e., throughput) of the mine. The resulting problem is a non-linear scheduling problem with maintenance constraints, blending and shared resources. In this paper, we decompose this problem into two parts: the blending, and the utilisation problems. We then focus our attention on the utilisation problem. We examine how to model and solve it using alternative approaches: specifically, constraint programming, MIQP and MINLP. We provide a repair heuristic based on an outer-approximation, and empirically demonstrate its effectiveness for solving the real-world instances of operational mine planning obtained from our industry partner.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

Aggoune, R.: Minimizing the makespan for the flow shop scheduling problem with availability constraints. European Journal of Operational Research 153(3), 534–543 (2004)

Bley, A., Boland, N., Froyland, G., Zuckerberg, M.: Solving mixed integer nonlinear programming problems for mine production planning with stockpiling. Tech. rep., University of New South Wales (2012). http://web.maths.unsw.edu.au/ froyland/bbfz.pdf

Burt, C.N., Lipovetzky, N., Pearce, A.R., Stuckey, P.J.: Approximate uni-directional Benders decomposition. In: Proceedings of PlanSOpt-15 Workshop on Planning, Search and Optimization AAAI-15 (2015)

Coal Shovel Clip Art: Accessed: 17/11/2014 (2014). gofreedownload.net/

Fox, M., Long, D.: PDDL2. 1: An extension to PDDL for expressing temporal planning domains. Journal of Artificial Intelligence Research 20, 61–124 (2003)

Gecode Team: Gecode: Generic constraint development environment (2006). http://www.gecode.org

HSL: a collection of Fortran codes for large scale scientific computation (2013). http://www.hsl.rl.ac.uk

Immersive Technologies: Accessed: 17/11/2014 (2014). http://www.immersivetechnologies.com/

Jamshidi, R., Esfahani, M.M.S.: Reliability-based maintenance and job scheduling for identical parallel machines. International Journal of Production Research 53(4), 1216–1227 (2015)

Khayat, G.E., Langevin, A., Riopel, D.: Integrated production and material handling scheduling using mathematical programming and constraint programming. In: Proceedings CPAIOR (2003)

Kubzin, M.A., Strusevich, V.A.: Planning machine maintenance in two-machine shop scheduling. Operations Research 54(4), 789–800 (2006)

Lipovetzky, N., Burt, C.N., Pearce, A.R., Stuckey, P.J.: Planning for mining operations with time and resource constraints. In: Proceedings of the Twenty-Fourth International Conference on Automated Planning and Scheduling, ICAPS 2014 (2014)

Moradi, E., Ghoma, S.F., Zandieh, M.: Bi-objective optimization research on integrated fixed time interval preventive maintenance and production for scheduling flexible job-shop problem. Expert Systems with Applications 38(6), 7169–7178 (2011)

Nethercote, N., Stuckey, P.J., Becket, R., Brand, S., Duck, G.J., Tack, G.R.: MiniZinc: towards a standard CP modelling language. In: Bessière, C. (ed.) CP 2007. LNCS, vol. 4741, pp. 529–543. Springer, Heidelberg (2007)

Sbihi, M., Varnier, C.: Single-machine scheduling with periodic and flexible periodic maintenance to minimize maximum tardiness. Computers & Industrial Engineering 55, 830–840 (2008)

Ta, C., Kresta, J., Forbes, J., Marquez, H.: A stochastic optimization approach to mine truck allocation. International Journal of Surface Mining 19, 162–175 (2005)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer International Publishing Switzerland

About this paper

Cite this paper

Burt, C.N., Lipovetzky, N., Pearce, A.R., Stuckey, P.J. (2015). Scheduling with Fixed Maintenance, Shared Resources and Nonlinear Feedrate Constraints: A Mine Planning Case Study. In: Michel, L. (eds) Integration of AI and OR Techniques in Constraint Programming. CPAIOR 2015. Lecture Notes in Computer Science(), vol 9075. Springer, Cham. https://doi.org/10.1007/978-3-319-18008-3_7

Download citation

DOI: https://doi.org/10.1007/978-3-319-18008-3_7

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-18007-6

Online ISBN: 978-3-319-18008-3

eBook Packages: Computer ScienceComputer Science (R0)