Abstract

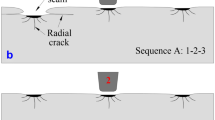

Cutterhead, cutterhead support and main beam are three main stressed components of TBM in tunneling process. To obtain the loadings on these components, a three-dimensional finite element model was established to simulate the excavating process, in which the progressive damage and failure model was introduced to simulate the formation and separation of cutting scraps. Then the stress and deformation distribution on these three components were analyzed based on the established model. Results reveal that the dangerous point appears in the intersection of corbel and cutterhead panel, with the max stress 237.7MPa which is less than the material yield limit 345MPa. The maximum deformation of the system is 1.96mm, which is a minute quantity comparing to structure size. So both the strength and stiffness of the components meet the requirements. This method can be utilized to get more useful information in complex conditions for the optimization of topological structure of the key components of TBM.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

Wang, L., Kang, Y., Cai, Z., Zhang, Q., Zhao, Y., Zhao, H., Su, P.: The energy method to predict disc cutter wear extent for hard rock TBMs. Tunn. Undergr. Space Technol. 28, 183–191 (2012)

Ramoni, M., Anagnostou, G.: Tunnel boring machines under squeezing conditions. Tunn. Undergr. Space Technol. 25, 139–157 (2010)

Hassanpour, J., Rostami, J., Zhao, J.: A new hard rock TBM performance prediction model for project planning. Tunn. Undergr. Space Technol. 26, 595–603 (2011)

Xia, Y., Wu, Y., Wu, F., Liu, W., Lin, L.: Study on simulation and mechanical properties of tunnel shield cutterhead. Computer Engineering and Applications 49, 248–251 (2013). (in Chinese)

Tao, L., Ning, X., He, F.: Finite element analysis for main beam of open-style TBM. Mechanical Engineering and Automation, 43–47 (2013). (in Chinese)

Qin, S., Li, R., Wang, D., Zhang, Y.: Finite element analysis of TBM ctterhead support based on ANSYS Workbench. Coal Mine Machinery 36, 238–240 (2015). (in Chinese)

Naderi-Boldaji, M., Alimardani, R., Hemmat, A., Sharifi, A., Keyhani, A., Tekeste, M.Z., Keller, T.: 3D finite element simulation of a single-tip horizontal penetrometer–soil interaction. Part I: Development of the Model and Evaluation of the Model Parameters Soil Tillage Res. 134, 153–162 (2013)

Abo-Elnor, M., Hamilton, R., Boyle, J.T.: 3D Dynamic analysis of soil–tool interaction using the finite element method. J. Terramech. 40, 51–62 (2003)

Hibbitt, Karlsson & Sorensen, Inc., ABAQUS Analysis User’s Manual Help Online, ABAQUS Documentation

Song, K., Wang, B.: Operation principle analysis of disc cutter on TBM. Construction Machinery, 71–74 (2007). (in Chinese)

Zhang, Q., Qu, C., Cai, Z., Kang, Y., Huang, T.: Modeling of the thrust and torque acting on shield machines during tunneling. Autom Constr. 40, 60–67 (2014)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer International Publishing Switzerland

About this paper

Cite this paper

Han, M., Cai, Z., Qu, C., Chen, K. (2015). Tunneling Simulation and Strength Analysis of Cutterhead System of TBM. In: Liu, H., Kubota, N., Zhu, X., Dillmann, R. (eds) Intelligent Robotics and Applications. Lecture Notes in Computer Science(), vol 9246. Springer, Cham. https://doi.org/10.1007/978-3-319-22873-0_40

Download citation

DOI: https://doi.org/10.1007/978-3-319-22873-0_40

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-22872-3

Online ISBN: 978-3-319-22873-0

eBook Packages: Computer ScienceComputer Science (R0)