Abstract

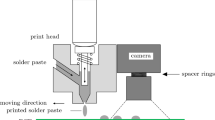

Laser bonding is one of important technology for devices Micro-interconnection and encapsulation. Laser has a characteristic of focusing, which makes the temperature of irradiate region dramatically increase in a short time, while the entire sample keeps a low temperature. Therefore, laser bonding has broad application prospects in micro-welding field. However, the welding path planning and positioning for micro-area welding need to overcome the shortcoming of low accuracy via using positioning blocks during traditional welding manner. This paper develops a visual identification and location system using a CCD (charge coupled device) camera. Based on the figure captured by CCD camera, an image processing system is used to extract the position and the size of the solder by PC software LabVIEW. Combined the collected information with the process requirements, the process planning system specifies the servo motor operating parameters and laser power parameters. This system can locate and identify arbitrary rectangular frame in the CCD field of view instead of pre-setting the size and position of solder. What’s more, based on the planned parameter, the switch of laser and the laser power value can adjust to laser path, making the laser processing more flexible.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

Fuyuan, L., Gonga, M., Xueb, H., et al.: Analysis on the temperature distribution and thermal effects in corner-pumped slab lasers. Optics and Lasers in Engineering 45, 43–48 (2007)

Mohan, A., Neal, C.B.O., Malshe, A.P., Foster, R.B.: A wafer-level packaging approach for MEMS & related microsystems using selective laser-assisted bonding (LAB). In: ECTC, vol. 21, pp. 099−1102 (2005)

Tao, Y., Malshe, A.P., Brown, W.D.: Selective bonding and encapsulation for wafer-level vacuum packaging of MEMS and related micro systems. Microelectronics Reliability 44(2), 251–258 (2004)

Lia, X., Wanga, L., Yanga, L., et al.: Modeling of temperature field and pool formation during linearlaser welding of DP1000 steel. Journal of Materials Processing Technology 214, 1844–1851 (2014)

Dai, Y., Li, P., Liu, Y., et al.: Integrated real-time monitoring system for strain/temperature distribution based on simultaneous wave length and time division multiplexing technique. Optics and Lasers in Engineering 59, 19–24 (2014)

Mathieu, A., Shabadi, R., Deschamps, A., Suery, M., et al.: Dissimilar material joining using laser (aluminum to steel using zinc-based filler wire). Optics & Laser Technology 39(3), 652–661 (2007)

Tan, A.W.Y., Tay, F.E.H.: Localized laser assisted eutectic bonding of quartz and silicon by Nd:YAG pulsed-laser. Sensor Actuators A 120(2), 550–561 (2005)

Bardin, F., Kloss, S., Wang, C., et al.: Laser bonding of glass to silicon using polymer for microsystems packaging. Microelectromechine System 16(3), 571–580 (2007)

Shuja, S.Z., Yilbas, B.S.: Laser heating of a moving slab: Influence pulse intensity parameter on temperature and stress fields. Optics & Laser Technology 70, 7–16 (2015)

Huang, Y., Li, M., Lai, Y., Chen, Z., Zhang, J.: Laser Bonding System for Semiconductor Device and MEMS Encapsulation. In: ICEPT-HDP, pp. 745−748 (2011)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer International Publishing Switzerland

About this paper

Cite this paper

Xiao, Y., Zhang, J. (2015). The Automatic Alignment System for Laser Bonding Based on Visual Identification and Location. In: Liu, H., Kubota, N., Zhu, X., Dillmann, R., Zhou, D. (eds) Intelligent Robotics and Applications. ICIRA 2015. Lecture Notes in Computer Science(), vol 9245. Springer, Cham. https://doi.org/10.1007/978-3-319-22876-1_46

Download citation

DOI: https://doi.org/10.1007/978-3-319-22876-1_46

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-22875-4

Online ISBN: 978-3-319-22876-1

eBook Packages: Computer ScienceComputer Science (R0)