Abstract

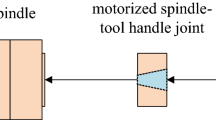

The clamping length of holder-tool often changes with the machining conditions and is the main factor affecting the stiffness and damping values of holder-tool interface. To avoid the need for repeating the measurements, the previous studies identify the joint stiffness-damping parameters based on genetic algorithm and calculate the joint parameters per unit area of holder-tool interface for response prediction. This paper proposes a simplified method to identify the joint parameters by simplifying the continuous contact interface to contact points in side of the clamping part. The equivalent joint stiffness-damping parameters are calculated by an inverse calculation method along the whole frequency band, which is more efficient than the genetic algorithm. The responses of holder-tool assembly with different clamping length are predicted based on the assumption of linear relationship between the stiffness-damping values and clamping length. At last, the experiment cases were carried out to verify the effective of the simplified method.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

Schmitz, T.L.: Predicting high-speed machining dynamics by substructure analysis. CIRP Ann. Manuf. Technol. 49, 303–308 (2000)

Schmitz, T.L., Davies, M.A., Kennedy, M.D.: Tool point frequency response prediction for high-speed machining by RCSA. J. Manuf. Sci. Eng. Trans. ASME 123, 700–707 (2001)

Schmitz, T.L., Scott Duncan, G.: Three-Component Receptance Coupling Substructure Analysis for Tool Point Dynamics Prediction. J. Manuf. Sci. Eng. Trans. ASME 127, 781–790 (2005)

Movahhedy, M.R., Gerami, J.M.: Prediction of spindle dynamics in milling by sub-structure coupling. Int. J. Mach. Tools Manuf. 46, 243–251 (2006)

Schmitz, T.L., Powell, K., Won, D., Duncan, G.S., Sawyer, W.G., Ziegert, J.C.: Shrink fit tool holder connection stiffness damping modeling for frequency response prediction in milling. Int. J. Mach. Tools Manuf. 47, 1368–1380 (2007)

Ahmadi, K., Ahmadian, H.: Modelling machine tool dynamics using a distributed parameter tool–holder joint interface. Int. J. Mach. Tools Manuf. 47, 1916–1928 (2007)

Ahmadian, H., Nourmohammadi, M.: Tool point dynamics prediction by a three-component model utilizing distributed joint interfaces. Int. J. Mach. Tools Manuf. 50, 998–1005 (2010)

Ghanati, M.F., Madoliat, R.: New Continuous Dynamic Coupling for Three Component Modeling of Tool–Holder-Spindle Structure of Machine Tools With Modified Effected Tool Damping. J. Manuf. Sci. Eng. Trans. ASME 134, 021015-1–021015-19 (2012)

Ertürk, A., Özgüven, H.N., Budak, E.: Analytical modeling of spindle-tool dynamics on machine tools using Timoshenko beam model and receptance coupling for the prediction of tool point FRF. Int. J. Mach. Tools Manuf. 46, 1901–1912 (2006)

Özsahin, O., Ertürk, A., Özgüven, H.N., Budak, E.: A closed-form approach for identification of dynamical contact parameters in spindle-holder-tool assemblies. Int. J. Mach. Tools Manuf. 49, 25–35 (2009)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer International Publishing Switzerland

About this paper

Cite this paper

Tang, X., Yan, R., Peng, F., Wu, P. (2015). A Simplified Method to Identify the Equivalent Joint Parameters of Holder-Tool Interface. In: Liu, H., Kubota, N., Zhu, X., Dillmann, R., Zhou, D. (eds) Intelligent Robotics and Applications. ICIRA 2015. Lecture Notes in Computer Science(), vol 9245. Springer, Cham. https://doi.org/10.1007/978-3-319-22876-1_51

Download citation

DOI: https://doi.org/10.1007/978-3-319-22876-1_51

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-22875-4

Online ISBN: 978-3-319-22876-1

eBook Packages: Computer ScienceComputer Science (R0)