Abstract

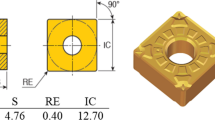

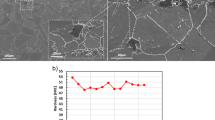

In aerospace industry, heat-resistant-super-alloys (HRSA) are widely used for its high strength, high hardness and low thermal diffusivity at high temperature. Flank milling is performed by employing the side of a cutter to touch the desired workpiece surface. Compared to traditional point milling, flank milling has attracted interest because of its high material removal rate and no scallops on the workpiece for single passage flank milling. Experimental investigation of the cutting performance in flank milling of HRSA is a preliminary step to the practical usage of HRSA, although this issue is absent to date. This paper firstly reviews the state of the art on the cutting forces and surface integrity in HRSA milling process. Then the experimental studies of cutting forces variation and surface integrity in flank milling of HRSA with PVD coated cemented carbide tools are presented. The cutting tests are performed at various cutting speeds (40–120 m/min), cutting depths (9–15 mm) and feed rates (0.03–0.09 mm/rev) in flank milling under lubricant condition. Additional measurements (surface roughness, residual stresses, microstructure and micro-hardness) are performed with the sample of the machined surface in addition to the cutting forces. The feed rate is the most influential parameter with surface roughness in flank milling operation. The tensile residual stresses are observed on the machined surface and a work hardening layer arises beneath the machined surface. The results show that the lower cutting forces and smaller micro-hardness generated with the higher cutting speed. The detailed analysis of the relationship between cutting parameters and surface micro-hardness is given in this paper.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

Smithberg, D.: Inconel 718 machining manual. In: Report 6M59-559. Manufacturing Research and Development, Boeing Commercial Airplane Company (1987)

Choudhury, I., El-Baradie, M.: Machinability of nickel-base super alloys: a general review. Journal of Materials Processing Technology 77, 278–284 (1998)

Alauddin, M., El Baradie, M., Hashmi, M.: End-milling machinability of Inconel 718. P I Mech Eng B-J Eng. 210, 11–23 (1996)

Richards, N., Aspinwall, D.: Use of ceramic tools for machining nickel based alloys. International Journal of Machine Tools and Manufacture 29, 575–588 (1989)

Liu, X.-W.: Five-axis NC cylindrical milling of sculptured surfaces. Computer-Aided Design 27, 887–894 (1995)

Bohez, E.L., Ranjith Senadhera, S., Pole, K., Duflou, J.R., Tar, T.: A geometric modeling and five-axis machining algorithm for centrifugal impellers. Journal of Manufacturing systems 16, 422–436 (1997)

Bedi, S., Mann, S., Menzel, C.: Flank milling with flat end milling cutters. Computer-Aided Design 35, 293–300 (2003)

Alauddin, M., Mazid, M., El Baradi, M., Hashmi, M.: Cutting forces in the end milling of Inconel 718. Journal of Materials Processing Technology 77, 153–159 (1998)

Devillez, A., Le Coz, G., Dominiak, S., Dudzinski, D.: Dry machining of Inconel 718, workpiece surface integrity. Journal of Materials Processing Technology 211, 1590–1598 (2011)

Pawade, R., Joshi, S.S., Brahmankar, P.: Effect of machining parameters and cutting edge geometry on surface integrity of high-speed turned Inconel 718. International Journal of Machine Tools and Manufacture 48, 15–28 (2008)

Zhou, J., Bushlya, V., Peng, R., Johansson, S., Avdovic, P., Stahl, J.: Effects of Tool Wear on Subsurface Deformation of Nickel-based Superalloy. In: 1st CIRP Conference on Surface Integrity. Bremen, Germany (2011)

Ezugwu, E., Wang, Z., Okeke, C.: Tool life and surface integrity when machining Inconel 718 with PVD-and CVD-coated tools. Tribology transactions 42, 353–360 (1999)

Jang, D., Watkins, T., Kozaczek, K., Hubbard, C., Cavin, O.: Surface residual stresses in machined austenitic stainless steel. Wear 194, 168–173 (1996)

Ducros, C., Benevent, V., Sanchette, F.: Deposition, characterization and machining performance of multilayer PVD coatings on cemented carbide cutting tools. Surface and Coatings Technology 163, 681–688 (2003)

Dudzinski, D., Devillez, A., Moufki, A., Larrouquere, D., Zerrouki, V., Vigneau, J.: A review of developments towards dry and high speed machining of Inconel 718 alloy. International Journal of Machine Tools and Manufacture 44, 439–456 (2004)

Outeiro, J., Pina, J.: R. M’saoubi, F. Pusavec, and I. Jawahir: Analysis of residual stresses induced by dry turning of difficult-to-machine materials. CIRP Annals-Manufacturing Technology 57, 77–80 (2008)

Ulutan, D., Ozel, T.: Machining induced surface integrity in titanium and nickel alloys: a review. International Journal of Machine Tools and Manufacture 51, 250–280 (2011)

Coelho, R., Silva, L., Braghini Jr, A., Bezerra, A.: Some effects of cutting edge preparation and geometric modifications when turning INCONEL 718™ at high cutting speeds. Journal of Materials Processing Technology 148, 147–153 (2004)

Sharman, A., Hughes, J., Ridgway, K.: Workpiece surface integrity and tool life issues when turning Inconel 718™ nickel based superalloy. Machining Science and Technology 8, 399–414 (2004)

Sharman, A., Hughes, J., Ridgway, K.: An analysis of the residual stresses generated in Inconel 718™ when turning. Journal of Materials Processing Technology 173, 359–367 (2006)

Axinte, D., Andrews, P., Li, W., Gindy, N., Withers, P., Childs, T.: Turning of advanced Ni based alloys obtained via powder metallurgy route. CIRP Annals-Manufacturing Technology 55, 117–120 (2006)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer International Publishing Switzerland

About this paper

Cite this paper

Zhuang, K., Zhang, X., Ding, H. (2015). Evaluation of Cutting Forces and Surface Integrity in Flank Milling of Heat-Resistant-Super-Alloys with Coated Cemented Carbide Tools. In: Liu, H., Kubota, N., Zhu, X., Dillmann, R., Zhou, D. (eds) Intelligent Robotics and Applications. ICIRA 2015. Lecture Notes in Computer Science(), vol 9245. Springer, Cham. https://doi.org/10.1007/978-3-319-22876-1_57

Download citation

DOI: https://doi.org/10.1007/978-3-319-22876-1_57

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-22875-4

Online ISBN: 978-3-319-22876-1

eBook Packages: Computer ScienceComputer Science (R0)