Abstract

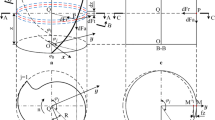

This paper presents the prediction of cutting forces in micro end-milling process based on the orthogonal cutting finite element simulation, which includes the exact tool trajectory with run-out, edge radius, rake angle, tool-chip contact and material mechanical and physical properties. The Johnson-Cook constitutive model parameters and sliding friction coefficient on the tool-chip interface are determined by the orthogonal cutting experiments. The finite element simulations of the micro orthogonal cutting process are carried out to determine the relations between tangential and feed cutting forces and uncut chip thickness by using the AdvantEdge FEM software. The effect of the run-out on the tool trajectory is considered to determine the exact uncut chip thickness. The cutting forces model is validated by micro slot end-milling experiments carried out on a three-axis ultra-precision machine. The predicted cutting forces are in good agreement with the experimental results.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

Waldort, D.J., DeVor, R.E., Kapoor, S.G.: A slip line field for ploughing during orthogonal cutting. ASME J. Manuf. Sci. Eng. 120, 693–699 (1998)

Vogler, M.P., Kapoor, S.G., Devor, R.E.: On the modeling and analysis of machinging performance in micro-endmilling, Part II: Cutting force prediction. ASME J. Manuf. Sci. Eng. 126, 695–705 (2004)

Woon, K.S., Rahman, M., Neo, K.S., Liu, K.: The effect of tool edge radius on the contact phenomenon of tool-based micromachining. Int. J. Mach. Tools Manuf. 49, 865–875 (2009)

Bissacco, G., Hansen, H.N., Slunsky, J.: Modelling the cutting edge radius size effect for force prediction in micro milling. CIRP Ann. 57(1), 113–116 (2008)

Malekian, M., Park, S.S., Jun, M.B.G.: Modeling of dynamic micro-milling cutting forces. Int. J. Mach. Tools Manuf. 49, 586–598 (2009)

Fang, N.: Slip-line modelling of machining with a rounded-edge tool, Part I: New model and theory. J. Mech. Phys. Solids. 51, 715–742 (2003)

Jin, X., Altintas, Y.: Slip-line field model of micro-cutting process with round tool edge effect. J. Mater. Process. Technol. 211, 339–355 (2011)

Lai, X., Li, H., Li, C., Ni, J.: Modelling and analysis of micro scale milling considering size effect, micro cutter edge radius and minimum chip thickness. Int. J. Mach. Tools Manuf. 48, 1–14 (2008)

Afazov, S.M., Ratchev, S.M., Segal, J.: Modelling and simulation of micro-milling cutting forces. J. Mater. Process. Technol. 210, 2154–2162 (2010)

Johnson, G.H., Cook, W.H.: A constitutive model and data for metals subjected to large strains, high strain rates and high temperatures. In: Proceedings of the Seventh International Symposium on Ballistics, pp. 541–547. The Haque, The Netherlands (1983)

Oxley, P.L.B., Stevenson, M.G.: Measuring stress/strain properties at very high strain rates using a machining tests. J. Inst. Metals. 95, 308–313 (1967)

Ozlu, E., Budak, E., Molinari, A.: Analytical and experimental investigation of rake contact and friction behavior in metal cutting. Int. J. Mach. Tools Manuf. 49, 865–875 (2009)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2015 Springer International Publishing Switzerland

About this paper

Cite this paper

Zhou, L., Peng, F., Yan, R., Dong, Q., Yang, C. (2015). Prediction and Experimental Validation of Micro End-Milling Forces with Finite Element Method. In: Liu, H., Kubota, N., Zhu, X., Dillmann, R., Zhou, D. (eds) Intelligent Robotics and Applications. ICIRA 2015. Lecture Notes in Computer Science(), vol 9245. Springer, Cham. https://doi.org/10.1007/978-3-319-22876-1_58

Download citation

DOI: https://doi.org/10.1007/978-3-319-22876-1_58

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-22875-4

Online ISBN: 978-3-319-22876-1

eBook Packages: Computer ScienceComputer Science (R0)