Abstract

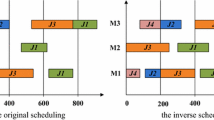

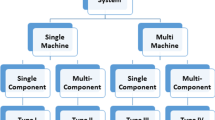

Job shop scheduling problem with machine maintenance has attracted the attention of many scholars over the past decades. However, only a limited number of studies investigate the availability of injection mould which is important to guarantee the regular production of plastic industry. Furthermore, most researchers only consider the situation that the maintenance duration and interval are fixed. But in reality, maintenance duration and interval may vary based on the resource age. This paper solves the job shop scheduling with mould maintenance problem (JSS-MMP) aiming at minimizing the overall makespan through a jointly schedule strategy. Particle Swarm Optimization Algorithm (PSO) and Genetic Algorithm (GA) are used to solve this optimization problem. The simulation results show that under the condition that the convergence time of two algorithms are similar, PSO is more efficient than GA in terms of convergence rate and solution quality.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Rajkumar, M., Asokan, P., Vamsikrishna, V.: A GRASP algorithm for flexible job-shop scheduling with maintenance constraints. Int. J. Prod. Res. 48(22), 6821–6836 (2010)

Berrichi, A., Amodeo, L., Yalaoui, F., Chatelet, E., Mezghiche, M.: Bi-objective optimization algorithms for joint production and maintenance scheduling: application to the parallel machine problem. J. Intell. Manuf. 20(4), 389–400 (2008)

Chan, T.S., Chan, L.Y., Chung, S.H., Finke, G., Timari, M.K.: Solving distributed FMS scheduling problems subject to maintenance: genetic algorithms approach. Robot. Comput. Integr. Manuf. 22(56), 493–504 (2006)

Chung, S.H., Lau, H.C.W., Ho, G.T.S., Ip, W.H.: Optimization of system reliability in multi-factory production networks by maintenance approach. Expert Syst. Appl. 36(6), 10188–10196 (2009)

Menges, G., Michaeli, W., Mohren, P.: How to make Injection Moulds, 3rd edn. Hanser Publishers, Munich (2001)

Wong, C.S., Chan, F.T.S., Chung, S.H.: A genetic algorithm approach for production scheduling with mould maintenance consideration. Int. J. Prod. Res. 50(20), 5683–5697 (2011)

Wong, C.S., Chan, F.T.S., Chung, S.H.: A joint production scheduling approach considering multiple resources and preventive maintenance tasks. Int. J. Prod. Res. 51(3), 883–896 (2013)

Niu, B., Bi, Y., Chan, F.T.S., Wang, Z.X.: SRBFO algorithm for production scheduling with mold and machine maintenance consideration. In: Huang, D.-S., Jo, K.-H., Hussain, A. (eds.) ICIC 2015. LNCS, vol. 9226, pp. 733–741. Springer, Cham (2015). doi:10.1007/978-3-319-22186-1_73

Kennedy, J., Eberhart, R.C.: Particle swarm optimization. In: Proceedings of IEEE International Conference on Neural Networks, Piscataway, NJ, USA, vol. 4, pp. 1942–1948 (1995)

Abdelhakim, A., Brahim, B., Mourad, B.: Branch-and-bound and PSO algorithms for no-wait job shop scheduling. J. Intell. Manuf. 27(3), 679–688 (2016)

Liu, L.L., Zhao, G.P., Ou’Yang, S.S., Yang, Y.J.: Integrating theory of constraints and particle swarm optimization in order planning and scheduling for machine tool production. Int. J. Adv. Manuf. Tech. 57(14), 285–296 (2011)

Shao, X.Y., Liu, W.Q., Liu, Q., Zhang, C.Y.: Hybrid discrete particle swarm optimization for multi-objective flexible job-shop scheduling problem. Int. J. Adv. Manuf. Tech. 67(9), 2885–2901 (2013)

Holland, J.H.: Adaptation in Natural and Artificial Systems. University of Michigan Press, Ann Arbor (1975)

Jia, Z.Y., Lu, X.H., Yang, J.Y., Jia, D.F.: Research on job-shop scheduling problem based on genetic algorithm. Int. J. Prod. Res. 49(12), 3585–3604 (2011)

Li, X.Y., Gao, L.: An effective hybrid genetic algorithm and tabu search for flexible job shop scheduling problem. Int. J. Prod. Eco. 174, 93–110 (2016)

Chan, T.S.F., Choy, K.L., Bibhushan, K.L.: A genetic algorithm-based scheduler for multiproduct parallel machine sheet metal job shop. Expert Syst. Appl. 38(7), 8703–8715 (2011)

Mosheiov, G., Sidney, J.B.: Scheduling a deteriorating maintenance activity on a single machine. J. Oper. Res. Soc. 61(5), 882–887 (2010)

Bean, J.C.: Genetic algorithms and random keys for sequencing and optimization. ORSA J. Comput. 6(2), 154–160 (1994)

Tasgetiren, M.F., Liang, Y.C., Sevkli, M., Gencyilmaz, G.: A particle swarm optimization algorithm for makespan and total flowtime minimization in the permutation flowshop sequencing problem. Eur. J. Oper. Res. 177(3), 1930–1947 (2007)

Acknowledgments

The work described in this paper was supported by grants from the Research Grants Council of the Hong Kong Special Administrative Region, China (Project No. PolyU 15201414). The Natural Science Foundation of China (Grant No. 71471158, 71571120, 71271140); and under student account code RUKH.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer International Publishing AG

About this paper

Cite this paper

Fu, X., Chan, F.T.S., Niu, B., Chung, S.H., Bi, Y. (2017). Minimization of Makespan Through Jointly Scheduling Strategy in Production System with Mould Maintenance Consideration. In: Huang, DS., Bevilacqua, V., Premaratne, P., Gupta, P. (eds) Intelligent Computing Theories and Application. ICIC 2017. Lecture Notes in Computer Science(), vol 10361. Springer, Cham. https://doi.org/10.1007/978-3-319-63309-1_51

Download citation

DOI: https://doi.org/10.1007/978-3-319-63309-1_51

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-63308-4

Online ISBN: 978-3-319-63309-1

eBook Packages: Computer ScienceComputer Science (R0)