Abstract

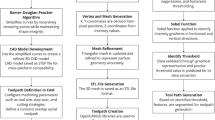

In this paper, we demonstrate a Hybrid Manufacturing software-HybridCAM. HybridCAM provides a variety of tool path generation methods for sculpture surfaces. The tool path patterns include contour-parallel pattern, zigzag pattern, and helical pattern. HybridCAM can input multiple format of models, such as IGS, STL, and STP, and can be applied to multi-axis Additive Manufacturing (AM) and multi-axis Subtractive Manufacturing (SM). We present several tool path patterns for different parts and different applications generated by HybridCAM. An actual experiment was carried out to verity the feasibility and practicality of the software.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Fessler, J., Merz, R., Nickel, A., Prinz, F.: Laser deposition of metals for shape deposition manufacturing. In: Solid Freeform Fabrication Symposium, pp. 117–124 (1996)

Lu, B.-H., Li, D.-C.: Development of the additive manufacturing (3D printing) technology. Mach. Build. Autom. 42, 1–4 (2013)

Turichin, G.A., Somonov, V.V., Babkin, K.D., Zemlyakov, E.V., Klimova, O.G.: High-speed direct laser deposition: technology. Equip. Mater. 125, 012009 (2016)

Gao, W., Zhang, Y., Ramanujan, D., Ramani, K., Chen, Y., Williams, C.B., et al.: The status, challenges, and future of additive manufacturing in engineering. Comput. Aided Des. 69, 65–89 (2015)

Bikas, H., Stavropoulos, P., Chryssolouris, G.: Additive manufacturing methods and modelling approaches: a critical review. Int. J. Adv. Manuf. Technol. 83, 389–405 (2016)

Griffith, M.L., Keicher, D.M., Atwood, C.L.: Free form fabrication of metallic components using laser engineered net shaping (LENS{trademark}). Office of Scientific & Technical Information Technical Reports (1996)

Thompson, S.M., Bian, L., Shamsaei, N., Yadollahi, A.: An overview of direct laser deposition for additive manufacturing; part I: transport phenomena, modeling and diagnostics. Addit. Manuf. 8, 36–62 (2015)

Ren, L., Sparks, T., Ruan, J., Liou, F.: Integrated process planning for a multiaxis hybrid manufacturing system. J. Manuf. Sci. Eng. 132, 237–247 (2010)

Kao, J.H., Prinz, F.B.: Optimal Motion Planning for Deposition in Layered Manufacturing (2001)

Eiamsa-Ard, K., Liou, F.W., Ren, L., Choset, H.: Spiral-like path planning without gap for material deposition processes. In: ASME 2006 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, pp. 983–991 (2006)

Foroozmehr, E., Kovacevic, R.: Effect of path planning on the laser powder deposition process: thermal and structural evaluation. Int. J. Adv. Manuf. Technol. 51, 659–669 (2010)

Tabernero, I., Calleja, A., Lamikiz, A.: Lacalle LNLD.: optimal parameters for 5-axis laser cladding ☆. Procedia Eng. 63, 45–52 (2013)

Calleja, A., Tabernero, I., Fernández, A., Celaya, A., Lamikiz, A.: Lacalle LNLD.: improvement of strategies and parameters for multi-axis laser cladding operations. Opt. Lasers Eng. 56, 113–120 (2014)

Ruan, J.: Automatic process planning and toolpath generation of a multiaxis hybrid manufacturing system. J. Manuf. Process. 7, 57–68 (2005)

Kobryn, P.A., Moore, E.H., Semiatin, S.L.: Effect of laser power and traverse speed on microstructure, porosity, and build height in laser-deposited Ti-6Al-4 V. Scripta Mater. 43, 299–305 (2000)

Acknowledgement

The authors gratefully acknowledge National Natural Science Foundation of China (51575386). The authors would also like to thank the experimental supporting from Wuhan HuaGong Laser Engineering Co., Ltd.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2017 Springer International Publishing AG

About this paper

Cite this paper

Zeng, X., Yan, C., Yu, J., He, S., Lee, CH. (2017). HybridCAM: Tool Path Generation Software for Hybrid Manufacturing. In: Huang, Y., Wu, H., Liu, H., Yin, Z. (eds) Intelligent Robotics and Applications. ICIRA 2017. Lecture Notes in Computer Science(), vol 10464. Springer, Cham. https://doi.org/10.1007/978-3-319-65298-6_78

Download citation

DOI: https://doi.org/10.1007/978-3-319-65298-6_78

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-65297-9

Online ISBN: 978-3-319-65298-6

eBook Packages: Computer ScienceComputer Science (R0)