Abstract

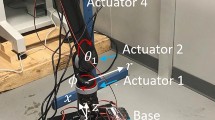

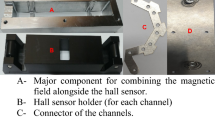

This paper addresses automated mapping of the remaining wall thickness of metallic pipelines in the field by means of an inspection robot equipped with Non-Destructive Testing (NDT) sensing. Set in the context of condition assessment of critical infrastructure, the integrity of arbitrary sections in the conduit is derived with a bespoke robot kinematic configuration that allows dense pipe wall thickness discrimination in circumferential and longitudinal direction via NDT sensing with guaranteed sensing lift-off (offset of the sensor from pipe wall) to the pipe wall, an essential barrier to overcome in cement-lined water pipelines. The data gathered represents not only a visual understanding of the condition of the pipe for asset managers, but also constitutes a quantative input to a remaining-life calculation that defines the likelihood of the pipeline for future renewal or repair. Results are presented from deployment of the robotic device on a series of pipeline inspections which demonstrate the feasibility of the device and sensing configuration to provide meaningful 2.5D geometric maps.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Ji, J., Robert, D., Zhang, C., Zhang, D., Kodikara, J.: Probabilistic physical modelling of corroded cast iron pipes for lifetime prediction. Struct. Saf. 64, 62–75 (2017)

Liu, Z., Kleiner, Y.: State of the art review of inspection technologies for condition assessment of water pipes. Measurement 46(1), 1–15 (2013)

Huang, C., Xinjun, W., Zhiyuan, X., Kang, Y.: Pulsed eddy current signal processing method for signal denoising in ferromagnetic plate testing. NDT E Int. 43(7), 648–653 (2010)

Xu, Z., Wu, X., Li, J., Kang, Y.: Assessment of wall thinning in insulated ferromagnetic pipes using the time-to-peak of differential pulsed eddy-current testing signals. NDT E Int. 51, 24–29 (2012)

Huang, C., Wu, X.: An improved ferromagnetic material pulsed eddy current testing signal processing method based on numerical cumulative integration. NDT E Int. 69, 35–39 (2015)

Ulapane, N., Alempijevic, A., Vidal-Calleja, T., Miro, J.V., Rudd, J., Roubal, M.: Gaussian process for interpreting pulsed eddy current signals for ferromagnetic pipe profiling. In: Conference on Industrial Electronics and Applications, pp. 1762–1767 (2014)

Skinner, B., Vidal-Calleja, T., Miro, J.V., De Bruijn, F., Falque, R.: 3D point cloud upsampling for accurate reconstruction of dense 2.5D thickness maps. In: Australasian Conference on Robotics and Automation, p. 7 (2014)

Xie, L., Scheifele, C., Xu, W., Stol, K.A.: Heavy-duty omni-directional mecanum-wheeled robot for autonomous navigation: System development and simulation realization. In: International Conference on Mechatronics, pp. 256–261. IEEE (2015)

Taheri, H., Qiao, B., Ghaeminezhad, N.: Kinematic model of a four mecanum wheeled mobile robot. Int. J. Comput. Appl. 113, 6–9 (2015)

Miro, J.V., Rajalingam, J., Vidal-Calleja, T., de Bruijn, F., Wood, R., Vitanage, D., Ulapane, N., Wijerathna, B., Su, D.: A live test-bed for the advancement of condition assessment and failure prediction research on critical pipes. Water Asset Manage. Int. 10(2), 3–8 (2014)

Rasmussen, C.E., Williams, C.K.: Gaussian Processes for Machine Learning. The MIT Press, MA, USA (2006)

Shi, L., Miro, J.V.: Towards optimized and reconstructable sampling inspection of pipe integrity for improved efficiency of NDT. In: World Water Congress, IWA, p. 8 (2016)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer International Publishing AG

About this paper

Cite this paper

Miro, J.V., Hunt, D., Ulapane, N., Behrens, M. (2018). Towards Automatic Robotic NDT Dense Mapping for Pipeline Integrity Inspection. In: Hutter, M., Siegwart, R. (eds) Field and Service Robotics. Springer Proceedings in Advanced Robotics, vol 5. Springer, Cham. https://doi.org/10.1007/978-3-319-67361-5_21

Download citation

DOI: https://doi.org/10.1007/978-3-319-67361-5_21

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-67360-8

Online ISBN: 978-3-319-67361-5

eBook Packages: EngineeringEngineering (R0)