Abstract

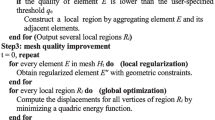

This paper describes a novel approach to improve the quality of non-manifold hexahedral meshes with feature preservation for microstructure materials. In earlier works, we developed an octree-based isocontouring method to construct unstructured hexahedral meshes for domains with multiple materials by introducing the notion of material change edge to identify the interface between two or more materials. However, quality improvement of non-manifold hexahedral meshes is still a challenge. In the present algorithm, all the vertices are categorized into seven groups, and then a comprehensive method based on pillowing, geometric flow and optimization techniques is developed for mesh quality improvement. The shrink set in the modified pillowing technique is defined automatically as the boundary of each material region with the exception of local non-manifolds. In the relaxation-based smoothing process, non-manifold points are identified and fixed. Planar boundary curves and interior spatial curves are distinguished, and then regularized using B-spline interpolation and resampling. Grain boundary surface patches and interior vertices are improved as well. Finally, the local optimization method eliminates negative Jacobians of all the vertices. We have applied our algorithms to two beta titanium datasets, and the constructed meshes are validated via a statistics study. Finite element analysis of the 92-grain titanium is carried out based on the improved mesh, and compared with the direct voxel-to-element technique.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

Asaro, R.: Micromechanics of Crystals and Polycrystals. Division of Applied Sciences 23, 1–115 (1983)

Blacker, T., Myers, R.: Seams and Wedges in Plastering: a 3D Hexahedral Mesh Generation Algorithm. Engineering With Computers 2, 83–93 (1993)

Cailletaud, G., Forest, S., Jeulin, D., Feyel, F., Galliet, I., Mounoury, V., Quilici, S.: Some Elements of Microstructural Mechanics. Acta Materialia 27, 351–374 (2003)

Canann, S., Tristano, J., Staten, M.: An Approach to Combined Laplacian and Optimization-based Smoothing for Triangular, Quadrilateral and Quad-dominant Meshes. In: 7th International Meshing Roundtable, pp. 479–494 (1998)

Chawla, N., Ganesh, V., Wunsch, B.: Three-Dimensional (3D) Microstructure Visualization and Finite Element Modeling of the Mechanical Behavior of SiC Particle Reinforced Aluminum Composites. Scripta Materialia 51, 161–165 (2004)

Dawson, P., Mika, D., Barton, N.: Finite Element Modeling of Lattice Misorientations in Aluminum Polycrystals. Scripta Materialia 47, 713–717 (2002)

Diard, O., Leclercq, S., Rousselier, G., Cailletaud, G.: Evaluation of Finite Element Based Analysis of 3D Multicrystalline Aggregates Plasticity Application to Crystal Plasticity Model Identification and the Study of Stress and Strain Fields near Grain Boundaries. International Journal of Plasticity 21, 691–722 (2005)

Field, D.: Laplacian Smoothing and Delaunay Triangulations. Communications in Applied Numerical Methods 4, 709–712 (1988)

Freitag, L.: On Combining Laplacian and Optimization-based Mesh Smoothing Techniques. Trends in Unstructured Mesh Generation 220, 37–43 (1997)

Ghosh, S., Moorthy, S.: Three dimensional Voronoi Cell Finite Element Model for Microstructures with Ellipsoidal Heterogeneties. Computational Mechanics 34, 510–531 (2004)

Groeber, M., Ghosh, S., Uchic, M., Dimiduk, D.: A Framework For Automated Analysis and Simulation of 3D Polycrystalline Microstructures: Part 1: Statistical Characterization. Acta Materialia 56, 1257–1273 (2008)

Huang, Y.: A User-Material Subroutine Incorporating Single Crystal Plasticity in the ABAQUS Finite Element Program. Division of Applied Sciences 23, 3647–3679 (1991)

Kanit, T., Forest, S., Galliet, I., Mounoury, V., Jeulin, D.: Determination of The Size of the Representative Volume Element for Random Composites: Statistical and Numerical Approach. International Journal of Solids and Structures 40, 3647–3679 (2003)

Knupp, P.: Achieving Finite Element Mesh Quality via Optimization of the Jacobian Matrix Norm and Associated Quantities. Part II - a Framework for Volume Mesh Optimization and the Condition Number of the Jacobian Matrix. International Journal for Numerical Methods in Engineering 48, 1165–1185 (2000)

Knupp, P.: Hexahedral and Tetrahedral Mesh Untangling. Engineering with Computers 17, 261–268 (2001)

Kral, M., Spanos, G.: Three-Dimensional Analysis of Proeutectoid Cementite Precipitates. Acta Materialia 47, 711–724 (1999)

Kumar, S., Kurtz, S.: Simulation of Material Microstructure Using a 3D Voronoi Tesselation: Calculation of Effective Thermal Expansion Coefficient of Polycrystalline Materials. Acta Metallurgica et Materialia 42, 3917–3927 (1994)

Lee, S., Rollett, A., Rohrer, G.: Three-Dimensional Microstructure Reconstruction Using FIB-OIM. Materials Science Forum, 915–920 (2007)

Lewis, A., Bingert, J., Rowenhorst, D., Gupta, A., Geltmacher, A., Spanos, G.: Two and Three Dimensional Microstructural Characterization of a Super-Austenitic Stainless Steel. Materials Science and Engineering 418, 11–18 (2005)

Lewis, A., Geltmacher, A.: Image-Based Modeling of the Response of Experimental 3D Microstructures to Mechanical Loading. Scripta Materialia 55(9), 81–85 (2006)

Lewis, A., Jordan, K., Geltmacher, A.: Determination of Critical Microstructural Features in an Austenitic Stainless Steel Using Image-Based Finite Element Modeling. Metallurgical and Materials Transactions A: Physical Metallurgy and Materials Science 39(5), 1109–1117 (2008)

Mitchell, S., Tautges, T.: Pillowing Doublets: Refining a Mesh to Ensure That Faces Share at Most One Edge. In: 4th International Meshing Roundtable, pp. 231–240 (1995)

Nygards, M.: Number of Grains Necessary to Homogenize Elastic Materials with Cubic Symmetry. Mechanics of Materials 35, 1049–1057 (2003)

Price, M., Armstrong, C.: Hexahedral Mesh Generation by Medial Surface Subdivision: Part i. International Journal for Numerical Methods in Engineering 38, 3335–3359 (1995)

Price, M., Armstrong, C.: Hexahedral Mesh Generation by Medial Surface Subdivision: Part ii. International Journal for Numerical Methods in Engineering 40, 111–136 (1997)

Qidwai, M., Lewis, A., Geltmacher, A.: Image-based Computational Modeling and Analysis of a Beta Titanium Alloy. Acta Materialia, in review (2009)

Rollett, A., Lee, S., Campman, R., Rohrer, G.: Three-Dimensional Characterization of Microstructure by Electron Back-Scatter Diffraction. Annual Review of Materials Research 37, 627–658 (2007)

Rowenhorst, D., Gupta, A., Feng, C., Spanos, G.: 3D Crystallographic and Morphological Analysis of Coarse Martensite: Combining EBSD and Serial Sectioning. Scripta Materialia 55, 11–16 (2006)

Schneiders, R.: A Grid-based Algorithm for the Generation of Hexahedral Element Meshes. Engineering with Computers 12, 168–177 (1996)

Schneiders, R., Weiler, F.: Octree-Based Generation of Hexahedral Element Meshes. In: 5th International Meshing Roundtable, pp. 205–216 (1996)

Shephard, M., Georges, M.: Three-Dimensional Mesh Generation by Finite Octree Technique. International Journal for Numerical Methods in Engineering 32, 709–749 (1991)

Shepherd, J.: Topologic and Geometric Constraint-Based Hexahedral Mesh Generation. University of Utah (2007)

Shontz, S., Vavasis, S.: A Mesh Warping Algorithm Based on Weighted Laplacian Smoothing. In: 12th International Meshing Roundtable, pp. 147–158 (2003)

Spanos, G., Rowenhorst, D., Lewis, A., Geltmacher, A.: Combining Serial Sectioning, EBSD Analysis, and Image-Based Finite Element Modeling. MRS Bulletin 33, 597–602 (2008)

Tautges, T., Blacker, T., Mitchell, S.: The Whisker-Weaving Algorithm: a Connectivity Based Method for Constructing All-hexahedral Finite Element Meshes. International Journal for Numerical Methods in Engineering 39, 3327–3349 (1996)

Youssef, S., Maire, E., Gaertner, R.: Finite Element Modeling of the Actual Structure of Cellular Materials Determined by X-ray Tomography. Acta Materialia 53, 719–730 (2005)

Zhang, Y., Bajaj, C.: Adaptive and Quality Quadrilateral/Hexahedral Meshing from Volumetric Data. Computer Methods in Applied Mechanics and Engineering 195, 942–960 (2006)

Zhang, Y., Bajaj, C., Sohn, B.: 3D Finite Element Meshing from Imaging Data. The special issue of Computer Methods in Applied Mechanics and Engineering on Unstructured Mesh Generation 194, 5083–5106 (2005)

Zhang, Y., Bajaj, C., Xu, G.: Surface Smoothing and Quality Improvement of Quadrilateral/Hexahedral Meshes with Geometric Flow. In: 14th International Meshing Roundtable, pp. 449–468 (2005)

Zhang, Y., Hughes, T., Bajaj, C.: An Automatic 3D Mesh Generation Method for Domains with Multiple Materials. Computer Methods in Applied Mechanics and Engineering (in press, 2009)

Zhao, Y., Tryon, R.: Automatic 3D Simulation and Micro-Stress Distribution of Polycrystalline Metallic Materials. Computer Methods in Applied Mechanics and Engineering 193, 3919–3934 (2004)

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2009 Springer-Verlag Berlin Heidelberg

About this paper

Cite this paper

Qian, J., Zhang, Y., Wang, W., Lewis, A.C., Qidwai, M.A.S., Geltmacher, A.B. (2009). Quality Improvement of Non-manifold Hexahedral Meshes for Critical Feature Determination of Microstructure Materials. In: Clark, B.W. (eds) Proceedings of the 18th International Meshing Roundtable. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-04319-2_13

Download citation

DOI: https://doi.org/10.1007/978-3-642-04319-2_13

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-642-04318-5

Online ISBN: 978-3-642-04319-2

eBook Packages: EngineeringEngineering (R0)