Abstract

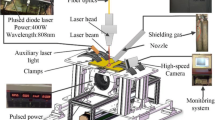

It is necessary to estimate the weld bead width and depth of penetration using suitable sensors during welding to monitor weld quality. Infra red sensing is the natural choice for monitoring welding processes as welding is inherently a thermal processing method. An attempt has been made to estimate the bead width and depth of penetration from the infra red thermal image of the weld pool using artificial neural network models. Real time infra red images were captured using IR camera during A-TIG welding. The image features such as length and width of the hot spot, peak temperature and other features are extracted using image processing techniques. These parameters along with their respective current values are used as inputs while the measured bead width and depth of penetration are used as output of the neural network models. Accurate ANN models predicting weld bead width and depth of penetration have been developed.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

Smith, J.S., Lucas, W.: Vision Based Systems for Controlling the Arc Welding operation and Inspecting the Weld Bead Profile. Welding in the World 43(suppl. issue), 10–22 (1999)

Houghton, M.A., Lucas, J.J., Lucas, W.: Vision Systems for Monitoring and Control of Arc Welding Operations. Soldagem Insp. Sao Paulo 12(4), 293–299 (2007)

Barry, J.M., Paley, Z., Adams Jr., C.M.: Heat conduction from moving Arc in Welding. Welding Journal 42(3), 97-s–104-s (1963)

Dorschu, K.E.: Control of Cooling rate in Steel Weld metal. Welding Journal 50(11), 49-s–62-s (1968)

Kannatey-Asibu Jr., E., Kikuchi, N., Jallard, A.R.: Experimental Finite Element Analysis of Temperature distribution during Arc Welding. Journal of Engineering Materials and Technology 111, 9–18 (1989)

Wickle, H.C., Chen, F., Nagarajan, S., Chin, B.A.: Survey of Infrared Sensing Techniques for Welding process Monitoring and Control. Journal of Chinese Institute of Engineers 21(6), 645–657 (1998)

Nagarajan, S., Chen, W.H., Chin, B.A.: Infrared Sensing for Adaptive Arc Welding. Welding Journal 68(11), 462-s – 466-s (1989)

Nagarajan, S., Banerjee, P., Chin, B.A.: Thermal imaging for Weld quality Control in Arc Welding processes. Transport Phenomena in Materials Processing 146, 171–178 (1990)

Chen, W., Chin, B.A.: Monitoring Joint Penetration using Infrared Sensing Techniques. Welding Journal 67, 181s–185s (1988)

Nagarajan, S., Banerjee, P., Chen, W.H., Chin, B.A.: Control of Welding Process using Infrared Sensors. IEEE Transactions on Robotics and Automation 8(1), 86–92 (1992)

Ghanty, P., Vasudevan, M., Chandrasekhar, N., Mukherjee, D., Maduraimuthu, V., Pal, N.R., Bhaduri, A.K., Bharat, P., Raj, B.: An Artificial Neural Network Approach for estimating weld bead width and depth of penetration from Infra red Thermal image of weld pool. Science and Technology of Welding and Joining 13(4), 395–401 (2008)

Wikle, H.C., Kottilingam, S., Zee, R.H., Chin, B.A.: Infrared Sensing Techniques for Penetration depth Control of the Submerged Arc Welding process. Journal of Materials Processing Technology 113, 228–233 (2001)

Menaka, M., Vasudevan, M., Venkatraman, B., Raj, B.: Estimating Bead Width and Depth of Penetration during Welding by Infrared Thermal imaging. Journal of British Institute of NDT 47(9), 564–568 (2005)

Rider, G.: Control of Weld pool size and position for Automatic and Robotic Sensory Welding. In: Proceedings of SPIE Third Inernational Conference on Robot Vision and Sensory Control, Cambridge, MA (November 1983)

Rider, G.: Measurement of Weld pool size by Self-scanned Photodiode Arrays. In: Proc. IEE International Conference on Low Light and Thermal Imaging Systems, London, pp. 3–5 (1975)

Malmuth, N.D., Hall, W.F., Davis, B.I., Rosen, C.D.: Transient Thermal Phenomena and Weld Geometry in GTAW. Welding Journal 53(9), 388–400 (1974)

Saeed, G., Zhang, Y.M.: Weld pool surface depth measurement using a Calibrated Camera and Structured light. Measurement Science and Technology 18, 2570–2578 (2007)

Pietrzak, K.A., Packer, S.M.: Vision based Weld Pool Width Control. ASME Journal of Engineering for Industry 116, 86–92 (1994)

Baneerjee, P., Liu, J.Y., Chin, B.A.: Infrared Thermography for Non-destructive Monitoring of Weld Penetration Variations. In: Liu, M. (ed.) Proceedings of the Japan U.S.A. Symposium on Flexible Automation, pp. 291–295. American Society of Mechanical Engineers (1992)

Govardhan, S.M., Chin, B.A.: Monitoring GTA Weld Puddle Geometry using Measured Temperature Gradients. In: David, S.A., Vitek, J.M. (eds.) Recent trends in Welding Science and Technology, pp. 383–386. American Society for Metals International Materials Park OH (1990)

Vasudevan, M.: Computational and Experimental Studies on Arc Welded Austenitic Stainless Steels. PhD Thesis, Indian Institute of Technology, Chennai (2007)

Nandhitha, N.M., Manoharan, N., Sheela Rani, B., Venkataraman, B., Vasudevan, M., Chandrasekar, Kalyana Sundaram, P., Raj, B.: Euclidean Distance Based Colour Image Segmentation Algorithm for Dimensional Characterization of Lack of Penetration from Weld Thermographs for Online Weld Monitoring. In: GTAW, 17th world Conference on Non-destructive testing WCNDT, Shanghai, China, October 26-28 (2008)

Lee, J.I., Um, K.W.: A Prediction of Welding process parameters by Prediction of Back bead geometry. Journal of Materials Processing and Technology 108, 106–113 (2000)

Chan, B., Pacey, J., Bibby, M.: Modeling Gas Metal Arc Weld Geometry using Artificial Neural Network Technology. Canadian Metallurgical Quarterly 38(1), 43–51 (1999)

Nandhitha, N.M., Manoharan, N., Sheela rani, B., Venkataraman, B., Vasudevan, M., Kalyana Sundaram, P., Raj, B.: Prediction of Torch Current Deviation using Feed Forward Neural Network for Monitoring Lack of Penetration from Thermal Images in GTAW of AISI Stainless Steel 316. International Journal of Intelligent Information Processing 3(2), 271–279 (2009)

Ghanty, P., Paul, S., Mukherjee, D.P., Vasudevan, M., Pal, N.R., Bhaduri, A.K.: Modelling Weld Bead geometry using Neural Networks for GTAW of an Austenitic Stainless Steel. Science and Technology of Welding and Joining 12(7), 649–658 (2007)

Vasudevan, M., Muruganath, M., Bhaduri, A.K., Raj, B., Prasad Rao, K.: Bayesian Neural Network Analysis of Ferrite number in Stainless Steel. Science and Technology of Welding and Joining 9(2), 109–120 (2004)

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2010 Springer-Verlag Berlin Heidelberg

About this paper

Cite this paper

Chokkalingham, S., Chandrasekhar, N., Vasudevan, M. (2010). Artificial Neural Network Modeling for Estimating the Depth of Penetration and Weld Bead Width from the Infra Red Thermal Image of the Weld Pool during A-TIG Welding. In: Deb, K., et al. Simulated Evolution and Learning. SEAL 2010. Lecture Notes in Computer Science, vol 6457. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-17298-4_28

Download citation

DOI: https://doi.org/10.1007/978-3-642-17298-4_28

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-642-17297-7

Online ISBN: 978-3-642-17298-4

eBook Packages: Computer ScienceComputer Science (R0)