Abstract

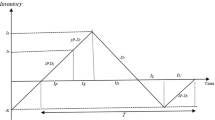

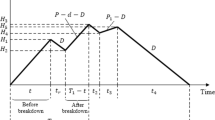

Producing new or recovering defective products often takes place on a common facility, with these activities carried out in lots. Consequently, there is a necessity to coordinate the production and rework activities with respect to the timing of operations and also with regard to appropriate lot sizes for both processes while completely satisfying a given demand. Thereby, it has to be taken into account whether the state of defective items that await rework worsens in the course of time or not. In this paper we present an EPQ model which addresses all of these aspects. Considering set-up and inventory holding costs, optimization algorithms are developed covering different planning situations.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

Flapper SDP, Fransoo JC, Broekmeulen RACM, and Inderfurth K (2002) Planning and control of rework in the process industries: a review. Production Planning & Control 13: 26-34

Goyal SK and Giri BC (2001) Recent trends in modeling of deteriorating inventory. European Journal of Operational Research 134: 1-16

Inderfurth K, Lindner G and Rahaniotis NP (2002) Lotsizing in a Production System with Rework and Product Deterioration. Working Paper, Otto-vonGuericke-University Magdeburg, Germany

Lindner G and Buscher U (2002) An Optimal Lot and Batch Size Policy for a Single Item Produced and Remanufactured on One Machine in the Presence of Limitations on the Manufacturing and Handling Capacity. Working Paper, Otto-von-Guericke-University Magdeburg, Germany

Minner S (2001) Economic Production and Remanufacturing Lot-sizing Under Constant Demands and Returns. In: B. Fleischmann et al. (eds) Operations Research Proceedings 2000. Springer, Berlin et al., pp 328-332

Misra RB (1975) Optimum production lot size for a system with deteriorating inventory. International Journal of Production Research 13: 495-505

Teunter RH and Flapper SDP (2003) Lot-sizing for a single-stage singleproduct production system with rework of perishable rework defectives. OR Spectrum forthcoming

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2003 Springer-Verlag Berlin Heidelberg

About this paper

Cite this paper

Inderfurth, K., Lindner, G., Rahaniotis, N.P. (2003). Lotsizing in a Production System with Rework and Product Deterioration. In: Leopold-Wildburger, U., Rendl, F., Wäscher, G. (eds) Operations Research Proceedings 2002. Operations Research Proceedings 2002, vol 2002. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-55537-4_16

Download citation

DOI: https://doi.org/10.1007/978-3-642-55537-4_16

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-540-00387-8

Online ISBN: 978-3-642-55537-4

eBook Packages: Springer Book Archive